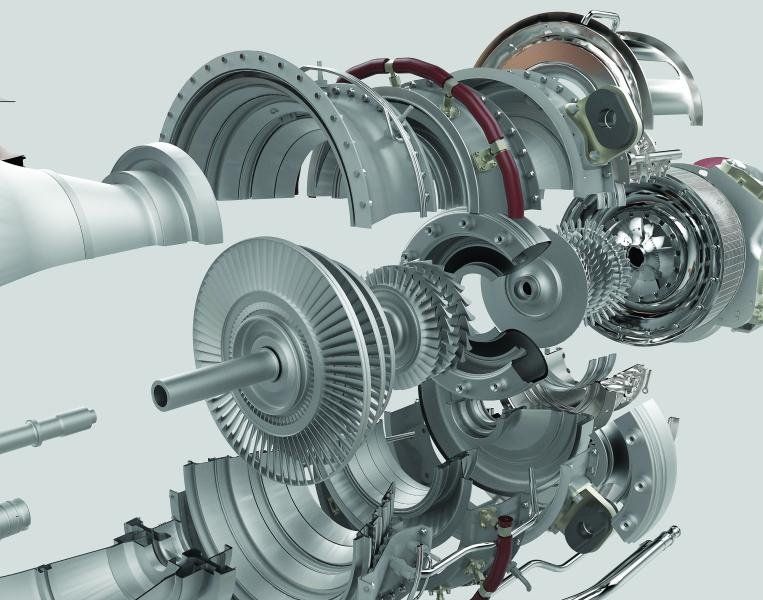

GE has test run a developmental version of its Advanced Turboprop (ATP) engine that contains 35 percent 3D printed parts. The ATP will be used in Cessna’s new Denali single and is a big part of the sales pitch for the aircraft. GE says 3D printing saves weight and is more precise than traditional construction methods. “With subtractive manufactured parts and assemblies, you traditionally use bolts, welds or other interfaces to attach the parts together, which adds weight to the engine,” Gordon Follin, who runs GE’s 3D printing department, told New Atlas. “On the ATP, additive reduces weight by eliminating those attaching features while also optimizing design of the parts.” The engine tested this week is just the beginning of the development process.

GE says that the final design will reduce 855 conventional parts in the engine to just 12 printed parts. Those parts include the sumps, bearing housings, frames, exhaust case, combustor liner, heat exchangers and stationary flowpath component. When it’s done, GE claims it will use 20 percent less fuel and provide 10 percent more power than comparable engines. Despite the record-setting achievement, the prototype was developed in a fraction of the time it normally takes because 3D printing makes the prototyping process so much faster. Parts that formerly took months to create in the conventional manner are printed in a few days and that speeds up the whole development process. The finished version of the engine is expected by the end of next year. AVweb’s Paul Bertorelli prepared a video report on the engine at NBAA 2015.