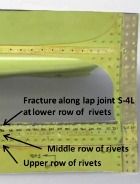

NTSB inspectors examining parts of the Southwest 737 fuselage that ruptured in flight on April 1 reported Monday that they found some rivets didn’t fit properly into their holes, and some of the holes were slightly offset or irregular in shape. While the NTSB update was purely factual, with no analysis, The New York Times said that according to experts, the findings may reveal manufacturing defects. “It means the assembly was wrong, it means the wrong tools were used, it means they were careless in drilling the holes, and maybe the drill was dull,” John J. Goglia, a former NTSB member, told the Times. Rivet holes that are irregular in shape would not disperse the stress of pressurization/depressurization cycles as evenly as a perfectly round hole would, Goglia told the Times. Boeing had no comment on the report.

The flight was at 34,000 feet when the rupture occurred, opening a hole in the fuselage 9 inches wide and 59 inches long, causing depressurization of the cabin. The flight crew conducted an emergency descent and diverted to Yuma International Airport, Yuma, Ariz. The aircraft has been delivered to Southwest in June 1996, and at the time of the accident, it had accumulated 48,740 hours of service and 39,781 cycles (a cycle is a takeoff and landing), the NTSB said.Inspections that were mandated after the accident turned up four 737s with crack indications at a single rivet and one with crack indications at two rivets. All of those aircraft had flown between 40,000 and 45,000 cycles, the NTSB said. The NTSB investigation is continuing.