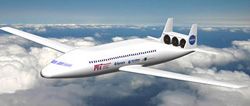

CNN Thursday highlighted the 70-percent fuel savings of an MIT-designed airliner built at least in part with technology and parts that don’t presently exist — but thanks to another effort altogether, fuel-saving shark-skin paint does. The MIT design would incorporate lifting body aerodynamics to greatly reduce the weighty load-bearing structure of its wings while also increasing stability, thus allowing for more structural weight savings at the tail. One stumbling block stalling production is that the aircraft’s engines are based on forecast technology … as is much of the aircraft’s structure and manufacturing process. As for present technology, a team in Bremen, Germany, has designed, created and applied a paint that mimics the exceptionally low drag features of sharks’ skin. Taking practical application of the technology one step further, the team has also developed the associated manufacturing technology to apply the paint on a production scale — right now — -but some challenges remain.

Yet to be determined is whether the cost of the paint would offset the single-digit efficiency increases it could produce (and the millions of tons of fuel that would save) if applied, globally. The paint’s creators believe their product could save nearly 4.5 million tons of fuel per year, if applied to every aircraft in the world. That, of course, would also lower operational costs while reducing CO2 emissions. One key to the paint is the nanoparticles it incorporates to provide sufficient protection from UV radiation, temperature changes and mechanical loads suffered by aircraft as a matter of course. Key to the production level application process is the stencil that creates the sharkskin structure. Complicating factors are the need to evenly apply the paint in the proper level over the stencil, which is detached from the base after UV radiation hardens the paint.