It was a typical late winter day in Chicago — overcast and in the low 50s. My student, Joe, was getting close to his instrument checkride and wanted to get some actual IFR practice in and, since I am reluctant to sign a student off for the instrument rating without some cloud time, I agreed.

It was a typical late winter day in Chicago — overcast and in the low 50s. My student, Joe, was getting close to his instrument checkride and wanted to get some actual IFR practice in and, since I am reluctant to sign a student off for the instrument rating without some cloud time, I agreed.

Joe and I met at the National Weather Service Office at Midway Airport to go over the weather and it sure did look like a perfect day for our mission. The current observation was 800 overcast and four miles visibility and the weather guessers expected a slow improvement from that to 3,000 and five with a slight chance of 500 and 1. That’s also standard in the Midwest — it seems like all winter there’s a chance of 500 and 1 just like all summer the forecast includes a chance of thunderstorms. I decided we’d go to the Michiana Regional Airport (SBN) in South Bend, Ind., to do multiple approaches. SBN is just over 50 miles from Midway and has all types of approaches so, while Joe did the walk around, I filed the flight plan.

Routine Flight?

Joe was one of my best students so my job that day was mainly to keep him legal and make suggestions on how to perfect his almost flawless technique. After several well-executed approaches, we decided to stop for lunch at the terminal restaurant. After lunch, we stopped by the FSS to recheck the weather and file and learned that the weather hadn’t changed since we left Midway, although the forecast improvement was somewhat slow in arriving there was no clue that the weather was going to rapidly deteriorate. Since I never feel an airplane has too much fuel, we topped off the Cherokee and launched for Midway. St. Louis, Mo., was the closest airport that didn’t have the chance of 500 and 1 in the forecast and that became our alternate for the return flight.

Imagine That, The Forecast Is Wrong!

When we got closer to Midway we began to get clues that all was not going to be as planned. Although the Midway ATIS was still reporting 400 and 1-1/2, I began to hear disturbing things on the approach frequency. Helicopter pilots were beginning to report in with messages like, "Midway, we see a parking lot here below us and we’re gonna put it down here." Now it’s been my experience that when it gets too cruddy for the helo guys to make it back home, there’s not much chance that little Cherokees are going to find the airport, but we were vectored for the ILS 13R approach to MDW. Just as I had trained him, Joe shot a flawless approach but when we got to DH and saw not even a glow through the clouds — and since the ATIS was now reporting indefinite 100 and in fog — we missed the approach and elected to proceed towards our filed alternate.

When we got closer to Midway we began to get clues that all was not going to be as planned. Although the Midway ATIS was still reporting 400 and 1-1/2, I began to hear disturbing things on the approach frequency. Helicopter pilots were beginning to report in with messages like, "Midway, we see a parking lot here below us and we’re gonna put it down here." Now it’s been my experience that when it gets too cruddy for the helo guys to make it back home, there’s not much chance that little Cherokees are going to find the airport, but we were vectored for the ILS 13R approach to MDW. Just as I had trained him, Joe shot a flawless approach but when we got to DH and saw not even a glow through the clouds — and since the ATIS was now reporting indefinite 100 and in fog — we missed the approach and elected to proceed towards our filed alternate.

A word here about alternates. As I’ve said before, St. Louis, Mo., was our legal filed alternate since it was the closest airport that didn’t have the chance of 500 and 1 included in its forecast. I did not intend to go all the way to St. Louis, however. I planned to land at the first airport we came across that was above minimums for the approaches available. There were several ILS-equipped airports on the way to STL and so I figured we’d soon be on the ground having another cup of coffee and bemoaning the midwestern weather.

The Problem Emerges

We were approaching Springfield, Ill., and talking to Capital Approach when I began to notice some abnormalities in the airspeed indicator. Every time Joe banked to make a course correction, the airspeed indicator needle would swing. This didn’t seem right and I asked Joe for control of the airplane. A few maneuvers convinced me that we had lost the pitot/static instruments. The lowest outside air temperature we had seen was 40 F so ice didn’t seem to be likely. This particular Cherokee had neither pitot heat nor an alternate static source so there were no quick and easy answers to our dilemma.

Now, I know that I’m going to get email suggesting that I should have broken the glass on the vertical speed indicator (VSI). Well, I tried that. It had always sounded like a good solution to me when it was presented in ground schools or hangar-flying sessions. Reality was another story. The problem with this solution is the position of the VSI in most small aircraft — behind the yoke. It’s impossible to get a good enough swing at the face of the instrument to have a hope of breaking the glass. Perhaps a hammer and/or a screwdriver would have helped, but I had left my tool chest at home that day!

Do You Want To Declare An Emergency? — You Betcha I Do!

Capital ATIS informed us that the weather in Springfield was now down to 300 and 1 — still doable on an ILS, but definitely on the way down. We had just contacted Capital Approach and I decided the best course of action was to confess our problem to ATC and ask for vectors to an ILS at Springfield. The controller asked if we wanted to declare an emergency and I told him we would do that. (Don’t ever be reluctant to declare an emergency when the situation warrants it. The horror stories you may have heard about the overly burdensome paperwork are mostly urban legend and the emergency handling gives you some advantages you wouldn’t otherwise have.)

Capital ATIS informed us that the weather in Springfield was now down to 300 and 1 — still doable on an ILS, but definitely on the way down. We had just contacted Capital Approach and I decided the best course of action was to confess our problem to ATC and ask for vectors to an ILS at Springfield. The controller asked if we wanted to declare an emergency and I told him we would do that. (Don’t ever be reluctant to declare an emergency when the situation warrants it. The horror stories you may have heard about the overly burdensome paperwork are mostly urban legend and the emergency handling gives you some advantages you wouldn’t otherwise have.)

The controller, in his desire to be helpful, started giving dual. He wanted me to select the alternate static source and turn on the pitot heat. When I told him we were not so equipped, he suggested breaking the face of the VSI. I thanked him for his help and told him that all I really wanted was vectors to the localizer about four miles outside the marker. He then gave us a heading and cleared us down to 2,600 feet. Now, if we had known where 2,600 feet was I probably wouldn’t have been having this discussion with the controller at all, but we just rogered the clearance and headed for the localizer.

The ILS

So, how does one shoot an approach with no altimeter, airspeed indicator or VSI? It’s not really as hard as it may seem. Remember being taught that pitch plus power equals performance? Well, I’m here to tell you how well that works. We had no idea how high we really were. We had been cruising at 4,000 feet before the failure and I figured we were still somewhere in that area, but I had no real way of knowing. I did know, however that 2,100 RPM in level flight in the Cherokee would give us about 90 KIAS and 1,700 RPM on a glideslope would also give us 90 KIAS and the proper rate of descent. So, an ILS was vital.

I told Joe that I thought he was an excellent instrument pilot, but that if it was all the same to him, this was going to be my approach. It was my job to hold the localizer and glideslope and it was Joe’s job to tell me when he saw runway lights. The last weather I heard gave the ceiling at 100 feet and the visibility at 1/8 mile. Certainly not VFR, but not illegal because of the declaration of emergency status.

The Landing

Just as the glideslope flared (usually about 50 feet AGL) Joe called the runway lights in sight. That was comforting since I had just reduced the power to idle and pitched the nose up a few degrees. The landing (arrival) was firm, but the airplane was reusable, so we declared the maneuver successful. By this time the fog was so thick that the follow-me truck sent out to fetch us almost ran into the wing. After the landing, I noted that the altimeter showed we were still at 3,200 feet and the airspeed indicator showed about 95 knots. Stopped. On the ground.

And The Problem Was…

The next day we had a mechanic look at the airplane he found that an accumulation of water in the pitot/static system had caused its failure. It was at that point that I put an alternate static source and pitot heat on my minimum equipment list for flight in clouds! Use of pitot heat would have helped to prevent the water ingestion — the reason use of an alternate static source is obvious.

Varying Symptoms

|

I noticed the problem because the instruments were giving indications that did not make sense under the circumstances. Every time Joe banked the airplane, the airspeed indicator swung. That’s not normal. Now, the cornerstone of instrument flying is that you believe your instruments, not your bodily sensations. The instruments don’t often lie to you, but when they do, you have to realize it quickly to avoid problems. Pitot/static system failures can present varied and contradictory symptoms, but the key is to recognize the erroneous readings.

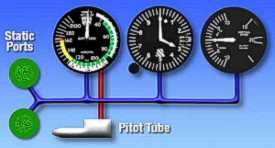

Let’s take a quick tour of the pitot/static system. I know you’ve studied this in ground school, but a review never hurts. Refer to Figure 1. The instruments that comprise the pitot/static system are the airspeed indicator, the altimeter, and the vertical speed indicator. The pitot tube is installed to point into the relative wind and measure the pressure of the ram air being forced into its opening by the speed of the airplane through the air. The static ports are located on the airplane in an area where they can measure the pressure of the undisturbed air around the airplane. This location can be on the sides of the fuselage, or, in the case of the Cherokees, on the back of the pitot mast.

Airspeed

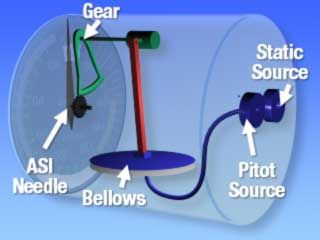

Figure 2.

|

The airspeed indicator uses inputs from both the pitot tube and the static ports and so it will be affected by a failure in either subsystem. It measures the difference between the ram air pressure from the pitot tube and the undisturbed air pressure from the static ports and displays this measurement as indicated airspeed. It’s an elegant system.

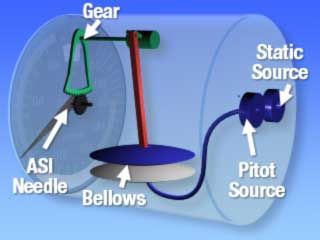

Take a look at Figure 2. The input from the pitot tube is routed to a bellows in the instrument. The static input goes into the case surrounding the bellows. An increase in pitot pressure expands the bellows as long as the static pressure does not also increase, as shown in Figure 3. The expansion of the bellows rotates a gear that turns the needle on the face of the airspeed indicator and displays indicated airspeed.

Should the pitot tube become suddenly blocked (along with its drain hole) — by ice, an insect or some other foreign material — it would probably go unnoticed in level flight. In a climb or a descent, however, an airspeed indicator relying on a blocked pitot tube would behave like an altimeter. The trapped pitot pressure is then measured against the varying static pressure and the result is displayed on the indicator. As you climb, the static pressure will become less, the trapped pitot pressure will remain the same, and the increasing difference between the two would be shown as increasing airspeed.

Figure 3. |

You might think this would be easy to diagnose, but a 727 crew died several years ago because they didn’t realize this problem. As they climbed to altitude, the airspeed kept increasing — beyond the capabilities of the airplane — and the crew kept pitching the nose up. They kept pitching the nose up until the airplane stalled and spun in. They airplane was on a ferry flight so no passengers were on board, but the crew perished because they didn’t recognize the problem.

A pitot tube that is slowly freezing over will probably cause the airspeed to decrease — possibly all the way to zero. This will probably get your attention because decreasing airspeed is perceived by most pilots to be a greater problem than increasing airspeed.

A blocked static port will cause varying symptoms depending upon the degree of blockage and the altitude at which it occurs. Generally, however, static port blockages will cause the airspeed indicator to increase with decreasing altitudes and decrease during a climb. The static pressure will be compared against the non-varying pitot pressure and the result displayed as airspeed. You can see that if the static port is blocked at a relatively high altitude there will be an increasing difference between static and pitot pressure as the airplane descends.

Altimeter and VSI

Since the altimeter and VSI rely only on static pressure input, they won’t be affected by blockages of the pitot tube. A pitot tube is more likely to be blocked by ice than the static port and so (usually, not always) there are fewer altimeter and VSI problems caused by ice. An altimeter affected by a blocked static system will simply continue to show the same reading it had when the blockage occurred.

Altimeters compare the incoming static pressure with the pressure within its internal sealed "aneroid wafers." As the outside static pressure decreases with altitude, the aneroid wafers expand and cause the altimeter needle to rotate around the dial. Blockage of the static source will stop the altimeter since it stops any change in pressure. The same effect will usually be noted with the VSI.

Some Do’s and Don’ts

So, what’s a pilot to do? As you scan the instrument panel during an instrument flight, you will usually only pick out those instruments that are abnormal. That’s what you’re looking for. The normal is what you want and you don’t have time or attention available to take note of normal. Here are a few do’s and don’ts to help you sort it all out.

So, what’s a pilot to do? As you scan the instrument panel during an instrument flight, you will usually only pick out those instruments that are abnormal. That’s what you’re looking for. The normal is what you want and you don’t have time or attention available to take note of normal. Here are a few do’s and don’ts to help you sort it all out.

DO consider pitot heat and alternate static sources as mandatory instruments for flight in actual instrument conditions.

DO conduct a careful preflight of all instrument systems.

DO keep your scan moving and identify any instrument(s) that give you conflicting information.

DO identify the instrument or system that is in error by determining what makes sense and what doesn’t. If the 727 crew had used this method, they might have identified a frozen pitot tube.

DO eliminate the offending instrument or system from your attention. Carrying instrument covers (usually used by diabolical CFIIs for partial-panel training) to cover the inoperative instruments can keep them from becoming a constant source of distraction. Remember, your scan will tend to pick up the abnormal.

DO remember that pitch plus power equals performance. As long as you have vacuum instruments available, you can keep the airplane level. Set the pitch and power for the performance you want and trust that the airplane will deliver.

DO consider a backup altimeter for serious instrument flying. Even the altimeter watches are good enough to keep you out of the terrain. Sky diving altimeters are also useful as a backup in an emergency.

DON’T allow your attention to become fixated on any one instrument or system. If you can’t figure out why an instrument is giving you the reading it is, there’s a good chance there’s a problem. Integrate the readings from all other instruments and determine which instrument is lying to you. Eliminate it.

In Conclusion

Pitot/static failures can take on many forms and the readings shown on the instruments can be many and varied. Your job as a pilot is to identify erroneous readings and decide how best to complete the flight without the offending instrument. There is little that can be done in flight other than turning on pitot heat or selecting alternate static sources to fix things.

Oh, and the paperwork required by the emergency Joe and I had? Minimal! The FAA met us on the ramp after the follow-me truck brought us in. Their main concern was with what had caused the failure in the first place. The paperwork was done quickly and the inspectors then showed us their favorite steak house where we had a good meal, a couple of drinks and a lot of hangar flying!