Braly’s article is followed by AVweb’s own comments (by Doug Ritter).

“I’m from the FAA and I’m here to help you.” When most of us hear thisphrase, we think of some poor pilot about to be given a lesson in bureaucraticarbitrariness courtesy of the FAA. Unfortunately, it’s not only pilots who must deal witha sometimes quixotic FAA. So do A&Ps, manufacturers and just about everyone who hasanything to do with aviation. There are times when it seems that it’s the good guys thatare singled out for persecution.

“I’m from the FAA and I’m here to help you.” When most of us hear thisphrase, we think of some poor pilot about to be given a lesson in bureaucraticarbitrariness courtesy of the FAA. Unfortunately, it’s not only pilots who must deal witha sometimes quixotic FAA. So do A&Ps, manufacturers and just about everyone who hasanything to do with aviation. There are times when it seems that it’s the good guys thatare singled out for persecution.

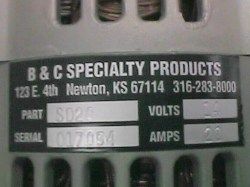

Bill Bainbridge, owner of B&C Specialty Products is anexample of one such individual whose situation remains unresolved. His story came to theattention of the general aviation community during the “Meet The Administrator”session at Oshkosh, last August. Bainbridge confronted outgoing (acting) FAA AdministratorBarry Valentine with the incongruous tale of the FAA’s enforcement action against himseeking a two thousand dollar fine for shipping one alternator and one voltage regulatorto Alaska, for installation under a Form 337 Field Approval in a Piper Super Cub. This,after 60 such installations had been previously supplied and ultimately approved in thesame manner.

Bill Bainbridge, owner of B&C Specialty Products is anexample of one such individual whose situation remains unresolved. His story came to theattention of the general aviation community during the “Meet The Administrator”session at Oshkosh, last August. Bainbridge confronted outgoing (acting) FAA AdministratorBarry Valentine with the incongruous tale of the FAA’s enforcement action against himseeking a two thousand dollar fine for shipping one alternator and one voltage regulatorto Alaska, for installation under a Form 337 Field Approval in a Piper Super Cub. This,after 60 such installations had been previously supplied and ultimately approved in thesame manner.

A recent interview with Bainbridge, of Newton, Kansas, reveals no progress in bringingthis dispute to an end, despite having brought the bizarre nature of this enforcementaction to the attention of the FAA at the highest levels, in the most public way, atOshkosh. Four months later the dispute remains unresolved, in spite of multiplerepresentations by various officials at the FAA that it would be dealt with expeditiously.

Bainbridge is responsible for developing a line of innovative,state of the art, and widely respected aircraft electrical components and systems for bothexperimental and certified aircraft. These include B&C’s popular lightweight startersfor Lycoming engines, high energy, low-maintenance gas recombinant batteries, andrecently, a 20 amp alternator based upon a widely used reliable Japanese automotivealternator, carefully adapted for aircraft use.

Bainbridge is responsible for developing a line of innovative,state of the art, and widely respected aircraft electrical components and systems for bothexperimental and certified aircraft. These include B&C’s popular lightweight startersfor Lycoming engines, high energy, low-maintenance gas recombinant batteries, andrecently, a 20 amp alternator based upon a widely used reliable Japanese automotivealternator, carefully adapted for aircraft use.

A popular figure year after year at his booth at Oshkosh, Bainbridge is almost alwaysfound dispensing experience and advice on all matters electrical to legions ofhomebuilders and certified aircraft owners, alike. Sadly, his ongoing experience with theFAA has soured him to such an extent that those flying certified aircraft may soon have toforego his quality products.

“I am seriously considering dropping all of my STCs and PMA’d parts, and justdealing with the homebuilt community,” remarked Bainbridge. This statement, by one ofgeneral aviation’s widely regarded “good guys,” is an indication of the depth ofthe crisis now threatening the ability of general aviation to maintain and upgrade itsfleet of aging aircraft.

FAA’s Rationale

The FAA has taken the position that sending along the sample Form 337 is evidence thatBainbridge intended the non-PMA’d parts to be installed on “certified” aircraft,in violation of FAR 21.303(a). That provision reads:

(a) Except as provided in paragraph (b) of this section, no person may produce a modification or replacement part for sale for installation on a type certificated product unless it is produced pursuant to a Parts Manufacturer Approval issued under this subpart.

(b) This section does not apply to the following:

(1) Parts produced under a type or production certificate.

(2) Parts produced by an owner or operator for maintaining or altering his own product

(3) Parts produced under an FAA Technical Standards Order.

(4) Standard parts (such as bolts and nuts) conforming to established industry or U.S. specification.

On its face, section 303(a) is violated when anyone (other than the original airframemanufacturer) ships any part for installation on a certified aircraft, unless it is aTSO’d or PMA’d part, or a nut or a bolt or similar standard industry part. It is easy tosee how the FAA might well interpret the shipment of B&C’s alternator, along with acopy of a previously approved Form 337, to fall within the scope of the forbidden partsshipments described in section 303(a).

However, that is not the end of it. According to Bainbridge the FAA said, early on,that it would drop the case if he would agree to just quit furnishing the Form 337s. Herefused, explaining, “they are public documents. Anyone can get them from the filesin Oklahoma City. How can they take away my free speech rights? Someone has to stand upand see this issue through.” Bainbridge also points out that there is a web site thatlists many examples of Form 337s that have been approved and more are being added to thelist everyday.

Bainbridge Surprised

Bainbridge was astonished to receive the letter from the FAAproposing a fine of $1,000 each, for shipping the alternator and the voltage regulator toa customer in Alaska. Bainbridge notes that he is very careful to notify his customersthat these parts are not STC’d and not PMA’d and adds that he has lost plenty of sales asa result. B&C makes it clear that the customer will have to obtain approval of theinstallation themselves. As a courtesy, if the customer inquires as to what would beinvolved in getting a field approval, Bainbridge sends along a packet that includes copiesof previously approved Form 337s which had been used in Alaska and elsewhere on some 60different installations of the B&C alternator. An A&P can use this as a guide toboth safely install the alternator and for filling out their own Form 337, after assuringall is OK with their local FAA inspector.

Bainbridge was astonished to receive the letter from the FAAproposing a fine of $1,000 each, for shipping the alternator and the voltage regulator toa customer in Alaska. Bainbridge notes that he is very careful to notify his customersthat these parts are not STC’d and not PMA’d and adds that he has lost plenty of sales asa result. B&C makes it clear that the customer will have to obtain approval of theinstallation themselves. As a courtesy, if the customer inquires as to what would beinvolved in getting a field approval, Bainbridge sends along a packet that includes copiesof previously approved Form 337s which had been used in Alaska and elsewhere on some 60different installations of the B&C alternator. An A&P can use this as a guide toboth safely install the alternator and for filling out their own Form 337, after assuringall is OK with their local FAA inspector.

While, technically, a previously approved Form 337 does not authorize or require a FSDOinspector to approve a subsequent similar installation, most inspectors, as a rule, havehistorically looked at such approvals as at least providing them with a “comfortzone” with regards to the installation. Recommended procedure has always been to gettogether with the inspector before commencing any sort of field approval and clearlydefining what the inspector wants and expects in terms of both the installation itself andthe supporting data package, drawings, etc. Depending upon the inspector and the matter inquestion, this can be little more than notes on the Form 337 to drawings and flight testresults.

In the case in question, the Super Cub owner says he receivedprior approval from the Anchorage FSDO via phone before ordering the alternator. The FAAlater denied they had done so and subsequently the FSDO inspector, Walter Zackowitz,refused to sign off on the Form 337 and insisted that a one-time STC, an involved,expensive and time consuming process, was the only acceptable solution. There then ensueda six month fight between the owner and the FAA, eventually culminating, only after theintervention of Ted Stevens, U.S. Senator from Alaska, with the approval of the Form 337by a different inspector from the same FSDO. Unfortunately, in the meantime a complainthad been filed against Bainbridge accusing him of selling “suspected unapprovedparts.” The rest, as they say, is history.

In the case in question, the Super Cub owner says he receivedprior approval from the Anchorage FSDO via phone before ordering the alternator. The FAAlater denied they had done so and subsequently the FSDO inspector, Walter Zackowitz,refused to sign off on the Form 337 and insisted that a one-time STC, an involved,expensive and time consuming process, was the only acceptable solution. There then ensueda six month fight between the owner and the FAA, eventually culminating, only after theintervention of Ted Stevens, U.S. Senator from Alaska, with the approval of the Form 337by a different inspector from the same FSDO. Unfortunately, in the meantime a complainthad been filed against Bainbridge accusing him of selling “suspected unapprovedparts.” The rest, as they say, is history.

The FAA’s position appears to be a lot more concerned with the “appearance”of the matter, than with its substance. After all, the FAA’s own FSDO inspectors havealready approved dozens of these identical alternator installations under the FieldApproval process using the a Form 337. In fact, the precise alternator and regulator thatgave rise to the present enforcement action has also been “approved” by the thatsame Anchorage FSDO on numerous occasions.

Bainbridge explains he is not trying to be confrontational aboutthe matter. “If I tell the customer that I can’t sell this alternator for use on acertified aircraft, but only to homebuilders, the customer will simply hang up and callback an hour later and order the same alternator for some fictional 14 volt homebuilt theydon’t have in their garage. What good does that do? Is that really in the best interest ofaviation safety?”

Bainbridge explains he is not trying to be confrontational aboutthe matter. “If I tell the customer that I can’t sell this alternator for use on acertified aircraft, but only to homebuilders, the customer will simply hang up and callback an hour later and order the same alternator for some fictional 14 volt homebuilt theydon’t have in their garage. What good does that do? Is that really in the best interest ofaviation safety?”

Approximately two months ago, Bainbridge says he was told by the FAA’s Bill O’Brien, inWashington, “You have done nothing wrong. The FAA owes you a letter of apology. Weshould have this resolved by Wednesday.” Since then, O’Brien’s report on the Alaskanalternator dispute remains stalled somewhere on some unidentified bureaucrat’s desk inWashington. Bainbridge says he doesn’t know what, exactly, is in the report, nor does hehave any idea of when, or even if, it will ever see the light of day.

Not An Isolated Example

According to numerous sources in the general aviation maintenance and parts business,the B&C saga is not an isolated example of the problems they experience dealing withthe FAA. As general aviation pilots attempt to maintain their aging fleet of aircraft andtry to upgrade the systems and components to take advantage of continuing advances intechnology, they are dependent upon the FAA to facilitate these moves. However, in recentmonths, a window has opened onto the ever expanding difficulties that are being faced bythe businesses that must deal with the FAA aircraft certification offices on a daily basisin their attempts to produce parts, obtain Supplemental Type Certificates and PartManufacturing Authority, and secure field approvals.

One such business is Monarch Air and Development, Inc. Owner Bill Barton has beendeveloping and certifying aftermarket parts for Cessna aircraft for many years. He isprobably best known for his highly rated fuel tanks and caps which provide a significantadditional margin of safety over OEM (original equipment manufacturer) parts. Recently,Barton established a newweb site describing some of the many frustrations he has encountered dealing with theFAA, inviting others in the industry to post their own experiences with the FAA STC andPMA process.

This”let-it-all-hang-out” web site is complete with a lengthy letter from themanager of the Special Certification Branch of the Seattle Aircraft Certification Office.This July 1996 letter isaddressed to “To all Domestic Type and Supplemental Certificate Holders under thecognizance of the Special Certification Branch.” The distribution list at the end ofthe letter includes over 50 widely recognized companies who manufacture parts for generalaviation aircraft that are located in the jurisdiction of the Seattle ACO.

The bottom line of the letter is that the Seattle Aircraft Certification Office is nolonger able to review and act upon any of the projects submitted by anyone in the Seattlearea in a timely manner. The fifty different businesses were told to expect it to takeover four months before any FAA project engineer would even read their project proposalsafter they were submitted to the FAA.

The letter begins with the following ominous message for the businesses that dependupon the FAA for their very existence, and the aircraft owners and pilots who depend uponthem for maintaining and improving the safety and reliability of their aircraft:

“The FAA, like you in industry, currently faces increasing pressure to do more with less. Many new FAA programs such as the Aircraft Certification Service Evaluation Program (ACSEP), Suspect Unapproved Parts (SUPS), Aviation Rulemaking Advisory Committee (ARAC), designee oversight, etc., have been implemented with no corresponding increase in FAA resources. The FAA budget, as with other government agencies, is being cut in many areas and in others, not growing commensurate with the demand. Consequently, our office is not staffed to address all of the FAA and your companies’ programs concurrently and must, therefore, now face some tough choices on work program priorities.”

The letter elaborates,

“All Supplemental Type Certificates (STC) and design approvals will be delayed when this office is involved in a significant continued airworthiness project….

… For all STC and design approval projects, a minimum of four months should be expected before the project will be reviewed by the assigned project engineer…. Projects submitted without DER support will receive the lowest priority.”

Of particular significance, the letter states,

“Onetime STC’s and coordinated field approvals will be discouraged by this office. These type of projects will have the lowest priority.”

The letter then makes it clear that outsiders need not apply.

“OutofRegion projects including projects supported by DER’s reporting to this office will not be accepted. Projects submitted by Canadian companies without facilities in our geographic region will not be accepted.”

As you might expect, this official FAA bombshell stirred up considerable concern amongthe affected business entities. Ultimately, a confrontation occurred in a meeting held onAugust 13, 1997. As a direct result of that meeting , the FAA issued another letterpromising to remedy problems resulting from the long delays in getting an initial reviewof projects and to eliminate “retaliation” by project engineers when applicantsseek review of often unreasonable low level decisions to higher management levels withinthe Special Certification Office.

When we spoke with Barton of Monarch Air this past week, he stated that there has beensome improvement in the situation, but that the system “is still, basically,broken”.

Among the matters which he cites as needing immediate major overhaul is the practice ofthe FAA in requiring extensive (and therefore, expensive) DER (Designated EngineeringRepresentative) participation in projects, but failing to actually delegate any of thesubstantive work and approvals to the DERs. Further, Barton notes that there is almostendless “second guessing” by the FAA project engineers of those few DERdelegations that actually are permitted.

Barton readily rattles off a long list of “horror stories” about unfoundeddelays (two years or more) in routine STC projects, including strongly suspected, butadmittedly unprovable, interference in some of his projects by the original airframemanufacturer. This is hardly the first time this allegation has been made, and in at leastone instance involving Mooney Aircraft and an STC held by Rocket Engineering, thisinterference was substantiated in articles appearing in The Aviation Consumer.

At one point, according to Barton, one project was being repeatedly held up because thematerials specified in the product design included routine “industrialdisclaimers” on the material documents. Apparently, these routine disclaimers werecausing someone in the Special Certification Office some heart burn. In the end, it tookBarton demanding that the FAA shut down Boeing for using materials with the samedisclaimers before he was able to move the project off of dead center.

Not Just The Pacific Northwest

These problems are not confined to the Pacific Northwest. AVweb has spoken withnumerous other businesses that routinely develop replacement parts or new products for usein general aviation aircraft Without exception, they all have experienced the same orsimilar kinds of delays documented in the Seattle Special Certification Office letter.These experiences cover essentially all of the FAA regions across the United States.

The complaints fall into a now familiar pattern:

The FAA is unable to process projects and have them reviewed by appropriately trained project engineers on a timely basis. There is virtually no concern within the FAA, that to the affected businesses, time is money and raising costs can affect the affordability, even the viability of products.

“I can’t be concerned about the cost, my only concern is safety.” This refrain is one of the most frustrating excuses that users hear by which FAA employees avoid serious discussions of alternative means and methods of “showing compliance” with the FARs by more cost effective methods. This despite the fact that in many instances the STC’s being sought are for parts or improvements that would raise the level of safety and raising costs may preclude their certification.

The FAA now requires virtually every applicant for an STC to obtain expensive DER “support”, but then frequently ignores all input and advice from the FAA approved DER and seldom lets the DER actively assist in the design and approval of the test plans and the execution of those plans, other than to be “an observer” and other than to “review data”.

Phone calls sometimes go unreturned for days at a time, although this varies in different regions of the country. Weeks or months may pass before FAA personnel can arrange to be present for the FAA’s required tests. Even when arrangements are made, postponements can occur and result in additional weeks or months of delay

Even when the development and FAA monitored testing is finally completed, weeks, sometimes months, may pass before required paperwork is completed and made available, allowing products to be shipped to customers.

All but a very few (Bainbridge and Barton, being exceptions) are totally convinced thatif their name is revealed in any public forum, then they will be the object of retaliationby the bureaucrats that they must deal with in the FAA. Thus inhibited, much of the FAA’sobjectionable behavior goes unreported for fear of such retribution. Retribution that inpart has been admitted to by the FAA in the Seattle ACO’s letter.

One holder of multiple STCs was forced to wait over five months for the FAA to schedulea one hour PMA inspection necessary in order that the company could begin shipping longpreviously STC’d parts. During this interval, it was perfectly legal and proper for thecompany to install the same parts at their facility as part of another STC, they justcouldn’t break out that portion of the kit and ship them without the PMA, which took fivemonths just to schedule. In fact, the FAA employee, was finally so frustrated, that hetook off one weekend and ended up making the inspection on a Saturday on his own time.

In another case, a company waited nearly three months for an FAA flight test pilot tobe available to schedule a flight.

Often the FAA requires multiple people, such as a test pilot, a project engineer, and aMIDO (Manufacturing Inspection District Office) inspector to be present to”witness” even the most simple of tests. These people all have more on theirschedule than they can gracefully handle. Thus, finding a date, when all three of these”essential” people can all travel to the company facilities to witness a test,can take weeks or months. If the weather goes bad, on the day of the scheduled test, itcan take another month or more to find a single date when all three different FAAemployees have an opening on their schedules.

A significant part of the problem appears to be that the MIDO offices are unwilling tolet the Aircraft Certification Office employees do a “conformity” inspection(confirming that parts produced match the engineering drawings and specifications), andthe ACOs do not trust the MIDO inspectors to witness even the most basic ground or flighttests to collect routine data.

Companies have offered to try to get around these scheduling and time consumingbottlenecks by video taping the entire test process and having DERs, a certifiedrepresentative of the FAA, present to be a witness. So far, few of these attempts atreducing costs and time consuming FAA involvement have met with approval, despite theFAA’s pronounced lack of internal resources.

In most instances, those contacted by AVweb, who have substantial experiencewith the FAA professionals involved with STCs and the PMA process, agree that with somenotable exceptions, the individual FAA employees are generally all “good”people. There are the usual bureaucratic exceptions to this rule, but the real problemappears to be FAA employees that are caught up in trying to administer an unworkable andunresponsive system.

It is Barton’s belief that the only way to force the FAA to reform the system is to getCongressional hearings and he is focused upon that objective. In describing his effortsand desires, he makes reference to the recent IRS hearings, with various witnessestestifying behind screens to protect them from retaliation.

Over the last month, a discussion involving these issues hastaken place on CompuServe’s Aviation Special Interest Group (AVSIG) forum. During thecourse of that discussion, the widely respected former FAA Associate Administrator forRegulation and Certification, Tony Broderick, acknowledged that the STC system was inserious need of improvement, if not outright overhaul. He also expressed support for thegreatly increased use of DERs, even going so far as to support the delegation toappropriate DERs of entire STC projects. That simple change would make a world ofdifference.

Over the last month, a discussion involving these issues hastaken place on CompuServe’s Aviation Special Interest Group (AVSIG) forum. During thecourse of that discussion, the widely respected former FAA Associate Administrator forRegulation and Certification, Tony Broderick, acknowledged that the STC system was inserious need of improvement, if not outright overhaul. He also expressed support for thegreatly increased use of DERs, even going so far as to support the delegation toappropriate DERs of entire STC projects. That simple change would make a world ofdifference.

Mary’s Ghost?

From the point of view of the pilots and owners of typical general aviation aircraft,the high price and slow development of improved replacement parts and modifications fortheir aging aircraft is seriously aggravated by the FAA’s current passionate pursuit ofso-called “unapproved parts” and “suspected unapproved parts” (howthat for fedspeak?), as exemplified by the current enforcement action against Bainbridgeover B&C’s highly regarded standby alternator.

The FAA’s current fascination with unapproved parts is primarilya result of threats from the former DOT Inspector General, Mary Schiavo, to pursue FAAofficials for failing to take action on the “problem,” according to her, ofunapproved parts, concerns later taken up by a Congress eager to latch onto anything thatmakes it look like it cares.

The FAA’s current fascination with unapproved parts is primarilya result of threats from the former DOT Inspector General, Mary Schiavo, to pursue FAAofficials for failing to take action on the “problem,” according to her, ofunapproved parts, concerns later taken up by a Congress eager to latch onto anything thatmakes it look like it cares.

This pursuit of “unapproved parts” is widely regarded by the general aviationcommunity as a totally misplaced application of the FAA’s dwindling resources. For years,it has been a common practice for mechanics to make modifications to general aviationaircraft and to use non-PMA’d and non-TSO’d parts to make a variety of improvements ingeneral aviation aircraft. One individual we know that is deeply involved with a number ofprojects requiring STCs, observed that, “virtually every instrument panel of everyaircraft built in the 1960s and 1970s sports at least one example of such aninstallation.”

The FAA’s argument, expressed during the course of the AVSIG discussions (in the caseof the B&C alternator, for example) is that it is impossible for any mechanic orowner in the field to know what the quality of the alternator really is, since it was notproduced under an approved aircraft quality assurance system. The FAA’s Holy Grail in thisregard is something it calls “approved data”. No approved data, nocertification, no PMA, no STC, no TSO and apparently, no Form 337 approval.

From the perspective of general aviation, the question raised by those in the field isthat if there is no data to support a finding of any safety issue with so calledunapproved parts, as the lack of accidents apparently shows, then why change pastpractices and start enforcing new rules that restrict or eliminate such practices?

Can A&Ps Be Trusted?

Most general aviation owners and pilots are perfectly content to let their mechanicsevaluate various products produced for their aircraft and to install and test them asappropriate. Obviously, this requires an exercise of judgment on the part of bothmechanics and owners. From the owner and mechanic’s point of view, this judgment callalmost always includes consideration of the alternative to the proposed installation, mostoften an OEM part with proven drawbacks, many impacting safety of flight. The FAA positionhas evolved to the point where it totally rejects the suggestion that any mechanic beallowed to “approve” any modification and installation of almost any part on theaircraft based upon a simple judgment call backed by considerable experience, often fargreater than that of the FAA inspector overseeing the mechanic.

Any discussion of this subject, quickly reduces itself to the absurd. What about, forexample, the installation of a coffee cup holder, commonly available in a camper supplystore? In one common modification, these are installed in place of the cigarette ashtrayson Bonanzas. Do these parts require an STC, PMA or TSO? The explicit language of FAR21.303(a) would authorize the FAA to prosecute your local camper supply store for sellingyou a simple cup holder, if you made the mistake of telling them in advance, that it wasgoing to be installed on your certified airplane.

Bainbridge responds that his alternator was sold with the express understanding by theowner that it could not legally be installed on his aircraft without a formal Form 337field approval. He maintains that such sales are either “legal” in and ofthemselves or they have been treated as legal for so many decades, that it isfundamentally unfair of the FAA to start to punish people and businesses for such conduct.It’s hard to find anyone outside the FAA that argues with that position.

Certainly, there is little question about the quality of the alternator in question,except perhaps in the mind of the FAA. This exact same alternator is currently used byMooney as part of its optional de-icing package for the Mooney Ovation. In short, it is analready approved and certified part, in another application. The difference is that inthis instance, being an airframe manufacturer, the FAA accepts Mooney’s judgment that thealternator is acceptable. (The core of the alternator is made in Japan, in an automotiveassembly facility. There is no FAA monitoring of that production facility and no special”aircraft quality assurance” at the point of original manufacturing of the corecomponents in the alternator. Nor is there any FAA monitoring of the modifications byB&C. Presumably, Mooney simply inspects the modified alternator, as it comes from B&C, in the same manner as all airframers inspect numerous parts used in theiraircraft that are not PMA’d or TSO’d.)

Building For Two Years

There have been warning signs of this impending problem, but by and large the generalaviation community has not been paying attention. Two years ago, in February of 1995, theFAA formally announced a “Notice Of Policy On Enforcement.” It included asummary which stated, “This is a notice of the FAA’s policy to enforce fullcompliance with certain regulations on producing modifications or replacement parts forsale for installation on type certificated products.”

When pushed on the subject, the FAA retreats behind claims that its “hands aretied” by the language of FAR 21.303(a). But, the truth of the matter is that theAdministrator only needs to keep on reading down a few lines in her own regulations tofind the solution. FAR 21.305, “Approval of materials, parts, process, andappliances,” contains the following language (excerpted):

“Whenever a material, part, process, or appliance is required to be approved under this chapter, it may be approved –

(a) Under a Parts Manufacturer Approval issued under 21.303;(b) Under a Technical Standard Order issued by the Administrator…;

(c) In conjunction with type certification procedures for a product; or

(d) In any other manner approved by the Administrator.”

It is difficult to argue, based on this plain language, that the FAA doesn’t haveregulatory authority that allows the Administrator to continue to approve the longstanding field approval process whereby over 60 of Bainbridge’s alternators have beensafely installed under a Form 337 on aircraft in Alaska. Bainbridge believes that theAdministrator had, for decades, accepted the Form 337 field approval process as just suchan alternative mechanism described in FAR 21.305(d) to show “approval” of hisparts, not to speak of the thousands of parts built and installed by others.

There is one thing everyone involved in these issues agrees about. Congress has notgiven the FAA the resources to timely process and approve the current applications forSTC’d products and modifications or field approvals. On the other hand, rather than usingthe resources it does have to find ways and means to open up and expedite thecertification process, all the users of the STC system see is ever more difficultcertification hurdles and, more recently, drastic enforcement actions against anyone whoattempt to solve real world problems in a rational, safe manner.

The Fix Is Obvious

Almost universally, those who rely upon the STC process agree that when all of thealternatives are carefully considered, there is really only one alternative that ispractical (given federal budget constraints) and that can realistically begin to solve theproblem for general aviation. That solution is for the FAA to start delegating, on awholesale basis, the complete STC process to their duly appointed DERs. The FAA could thenuse its limited resources to manage and supervise the DERs and quit trying to micro-managethe projects. To make this work, the FAA would have to substantially increase the numberof DERs that it does appoint, but there is no shortage of experienced engineers whounderstand what is required by the FAA.

For the owner or pilot, it all seems so simple. Is it safer for the bush pilot inAlaska to continue to fly with a 30 year old generator that frequently fails, and may havebeen overhauled a dozen times with so-called unapproved parts, or is it safer to install amodern, state-of-the-art alternator sold by B&C? Seems like a no-brainer to us.

AVweb’s View:

Show Me the Data …

For as long as we’ve been writing about aviation I’ve been hearing horror stories fromthose who must deal with the FAA to gain STCs, PMAs and field approvals. With rareexception, those complaining have declined to be identified for an article or to telltheir stories publicly for fear of retribution. It may have been bad, but it was betterthan being put out of business. It simply became a cost of doing business, albeit agenerally needless cost, to be passed on to the customer. Unfortunately, on more than afew occasions it has resulted in ideas being stillborn, in better and safer products nevercoming to market or making it into the airplanes we all fly.

Over the years they found ways around some of the most onerous obstacles, but it wasrarely a pleasant experience for most. Even those who have been doing it for years andhave sterling reputations find that every new application and new FAA hire brings with itnew nightmares. In recent years it has gotten worse. One must ask, why?

Disregarding that until recently the FAA had a dual mandate that included promotion ofaviation, the avowed bottom line purpose of the FAA has always been to promote safety.

While there are many ways to achieve that end, relying upon experience and good data tomake safety of flight decisions isn’t a bad way to start. Former FAA AssociateAdministrator of Regulation and Certification, Tony Broderick, used to say “show methe data” when pressed on most safety issues. Fair enough, I can live with thatattitude. You may still argue over data, but it’s a lot better than letting politics orself-serving bureaucrats drive rule making.

So, where’s the data that shows that the field approval system is unsafe? Where’s thedata that shows that so-called unapproved parts are causing serious accidents? Where’s thedata that says that field approvals using non PMA’d or TSO’d parts are killing pilots?Where’s the data that shows that a modern, well designed and built alternator, installedin accordance with generally accepted engineering principles by appropriately trained andcertified mechanics is unsafe? While we’re asking, where’s the data that suggests thatit’s a bad idea to have DERs with years more expertise and experience than the FAA’sproject engineers approve data for most relatively simple STCs. If you can’t show me thatdata, I’ll understand, because there isn’t any.

If It Ain’t Broke…

This, then is the crux of the problem. A system that worked for years has degeneratedto the point of uselessness with no rational basis for doing so. At a time when the FAAhas less and less resources to work with and ever more to do with those limited resources,why are they looking for ways to make the system even less productive.

There is no question that FAR 21.305 provides all the authoritythe FAA needs to solve these problems. What is lacking is any sense of urgency or needfrom FAA leadership. Meanwhile, while the FAA fiddle-farts around, general aviation istaking it on the chin. Good ides that make flying safer and more affordable arelanguishing, many not even being pursued because of the current regulatory environment.Those that make it through the process cost far more than they ought to. It’s time thatAOPA, EAA, NATA and the other alphabet organizations made solving this problem a priority.

The bottom line to finding a solution is recognizing that, ultimately, the FAA simplydoes not have the resources to do its job. The obvious solution to that bottleneck is tocreate alternative means of compliance that are timely and economical and still provide areasonable degree of safety and security.

Why Make A Federal Case Of This…

I’d hate to think it is necessary to hold congressional hearings with secret witnessesand expose the FAA to even greater public ridicule. With all the complaints from the FAAabout time wasted dealing with Congressional mandates and investigations, you would thinkthey’d be happy to try and solve problems before they reach that point. Yet, there’s noevidence that FAA management gives a hoot about the problem or that it is prepared to moveto find solutions in a timely manner.

A number of people involved in the process have volunteered to help draft workablerules that serve both the interests of safety and the needs of general aviation, our ownGeorge Braly among them. To date, the FAA has shown little interest in their help. Whenyou peel away the bureaucratic veneer, these problems are little different than thosefaced by businesses all over the world who have had to deal with downsizing and reducedbudgets. The solutions have been found by thinking outside the box, not by cutting offtheir nose to spite their face.

For the sake of all of us in general aviation, here’s hoping someone, somehow can getthe FAA leadership to get off its duff on this and start working towards a solution. Seemsto us the answer is simple: outsourcing! It may be something of a buzzword thesedays, but it’s the only practical answer. The FAA’s limited resources require that it quittrying to micro-manage routine certification projects. Instead, it should let the DERs, A&Ps, IAs and perhaps some new type designees do the routine modification andcertification work. Then, the FAA can use what resources it does have to monitor thesedesignees and others who can get the word done on a timely and cost effective basis.

Former Associate Administrator Tony Broderick is probably in abetter position than anyone to know, since all the FSDOs, ACOs and MIDOs used to report tohim. No longer restrained by FAA chains, Broderick recently commented on the CompuServeAVSIG forum:

Former Associate Administrator Tony Broderick is probably in abetter position than anyone to know, since all the FSDOs, ACOs and MIDOs used to report tohim. No longer restrained by FAA chains, Broderick recently commented on the CompuServeAVSIG forum:

“The FAA simply is not doing its job as the industry needs it done in this area, and I see no technical reason why they can’t do more delegation. .. The ‘legality’ of the [B&C] alternator approvals is one which I don’t think will be questioned, though ‘Mikey likes it’ is not a proper way to do business.”

Concerning the B&C fiasco, the Administrator needs to re-read FAR 21.305, and putthe Form 337 Field Approval process back on the same footing it has occupied for the last50 years.

All this needs to happen, and happen soon, before the situation degenerates anyfurther.