LATEST FROM GAMI! GAMI has received its long-awaited STC for the installation of GAMIjectorsTM on TCM IO-360 and TSIO-360 engines found on the Mooney 231, Piper Turbo-Arrow and Seneca, Cessna Skymaster (including Turbo and Pressurized), etc. Only the TSIO-360-MB engine (Mooney 252) is excluded from the STC. LATEST FROM GAMI! GAMI has received its long-awaited STC for the installation of GAMIjectorsTM on TCM IO-360 and TSIO-360 engines found on the Mooney 231, Piper Turbo-Arrow and Seneca, Cessna Skymaster (including Turbo and Pressurized), etc. Only the TSIO-360-MB engine (Mooney 252) is excluded from the STC.GAMI is also now offering GAMIjectorsTM for Lycomings! See AVweb’s in-depth review by Carl Marbach. |

One of the major benefits of afuel-injected engine over a carbureted one is that each cylinder of an injected enginetheoretically receives exactly the same amount of fuel as every other cylinder. Thecarbureted Continental O-470 used in the Cessna 182, for example, is notorious for havingsome cylinders that run rich while others run lean, while its fuel-injected sibling (theIO-470) has mixture distribution that is noticeably more even.

One of the major benefits of afuel-injected engine over a carbureted one is that each cylinder of an injected enginetheoretically receives exactly the same amount of fuel as every other cylinder. Thecarbureted Continental O-470 used in the Cessna 182, for example, is notorious for havingsome cylinders that run rich while others run lean, while its fuel-injected sibling (theIO-470) has mixture distribution that is noticeably more even.

But if you fly behind a fuel-injected Continental engine and ifyour aircraft is equipped with probe-per-cylinder EGT instrumentation (like an Insight GraphicEngine Monitor or a JPI 700), you know that the mixture distribution is still far fromperfect. As you lean the engine and watch the EGTs, you see that some cylinders reach peakEGT sooner than others. The usual procedure is to lean the engine by reference to theleanest cylinder – that is, the cylinder which reaches peak EGT first – and allow theother cylinders to operate at richer-than-optimum mixtures.

But if you fly behind a fuel-injected Continental engine and ifyour aircraft is equipped with probe-per-cylinder EGT instrumentation (like an Insight GraphicEngine Monitor or a JPI 700), you know that the mixture distribution is still far fromperfect. As you lean the engine and watch the EGTs, you see that some cylinders reach peakEGT sooner than others. The usual procedure is to lean the engine by reference to theleanest cylinder – that is, the cylinder which reaches peak EGT first – and allow theother cylinders to operate at richer-than-optimum mixtures.

Bear in mind that the leanest cylinder isn’t always the hottestcylinder. It is perfectly normal for the EGTs of different cylinders to peak at slightlydifferent temperatures, reflecting the inevitable cylinder-to-cylinder differences incompression, exhaust valve timing, EGT probe placement, and other factors. These minor EGTvariations are not a problem.

What is important is that all cylinders should reach peak EGT at the samemixture-control setting, so that when you lean one cylinder to the proper mixture, therest of the cylinders are properly leaned, too. Since the fuel injection system isdesigned to deliver the same amount of fuel to each cylinder, you’d think all thecylinders would operate at identical mixtures and would therefore reach peak EGT at thesame setting of the red knob. But unfortunately they don’t.

Look at the actual EGT graph for a typical six-cylinder big-boreContinental engine operating at cruise power. Note that while cylinders #4 and #5 of thisengine have the hottest peak EGTs, it’s actually cylinders #1 and #2 that are running theleanest; i.e., they reach peak EGT first as the mixture is leaned (around 14.5 GPH totalfuel flow). At this point, the richest cylinders (#5 and #6) are still runningsubstantially rich-of-peak.

Look at the actual EGT graph for a typical six-cylinder big-boreContinental engine operating at cruise power. Note that while cylinders #4 and #5 of thisengine have the hottest peak EGTs, it’s actually cylinders #1 and #2 that are running theleanest; i.e., they reach peak EGT first as the mixture is leaned (around 14.5 GPH totalfuel flow). At this point, the richest cylinders (#5 and #6) are still runningsubstantially rich-of-peak.

Many pilots are taught to lean to peak EGT on the first cylinder to reach peak (#1 inthis case), then to enrichen by 50F or so. If you leaned this engine in that fashion,you’d be running at about 16.5 GPH and cylinders #5 and #6 would be running very rich. Atbest, this is a waste of fuel. At worst, it could eventually result in fouled plugs, stuckrings, and bell-mouthed exhaust valve guides on those over-rich cylinders.

On the other hand, if you continued leaning this engine until cylinders #5 and #6 reachpeak EGT (at about 13.5 GPH), then the leanest cylinders would be more than 50Flean-of-peak…and the engine would probably start running rough.

What The TCM Engineers Missed

Why don’t these fuel-injected TCM engines have more even mixture distribution? Foryears, people thought it was due to random differences in volumetric efficiency of thecylinders, and overhaul shops started touting their exotic porting and polishing andflow-bench testing as a solution. But frankly, it didn’t help.

A handful of engine experts – including an Oklahoma attorney,aeronautical engineer and Bonanza owner by the name of GeorgeBraly – began to realize that the mixture maldistribution in these engines wasdecidedly non-random. They noticed that the rear cylinders (#1 and #2) were almost alwaysthe ones that ran leanest, and the front ones (#5 and #6) almost always the ones that ranrichest, just as we saw in the graph above. But why?

A handful of engine experts – including an Oklahoma attorney,aeronautical engineer and Bonanza owner by the name of GeorgeBraly – began to realize that the mixture maldistribution in these engines wasdecidedly non-random. They noticed that the rear cylinders (#1 and #2) were almost alwaysthe ones that ran leanest, and the front ones (#5 and #6) almost always the ones that ranrichest, just as we saw in the graph above. But why?

The first theory advanced was that the front cylinders had to breathe their inductionair through a longer path than the rear cylinders and therefore were getting less air,while the rear cylinders had a shorter induction path and got more air. If the rearcylinders got more air but the same amount of fuel, that would explain why they ran leanerand reached peak EGT first. Conversely, if the front cylinders got less air but the sameamount of fuel, that would explain why they ran richer and reached peak EGT last.

It was an appealing theory. But it was wrong! In fact, all cylinders in these enginesbreathe very nearly the same amount of air.

After investigating further and consulting with avery smart ex-TCM engineer, Braly discovered the real reason why the mixturedistribution was skewed. The TCM fuel injection system is a continuous-flow system, whichmeans that each injector nozzle sprays fuel into the intake port of its cylinder all thetime…even when the intake valve is closed. During those valve-closed periods, a certainamount of atomized fuel is sucked into the induction manifold beneath the cylinders and iscarried forward by the airflow through the induction system.

After investigating further and consulting with avery smart ex-TCM engineer, Braly discovered the real reason why the mixturedistribution was skewed. The TCM fuel injection system is a continuous-flow system, whichmeans that each injector nozzle sprays fuel into the intake port of its cylinder all thetime…even when the intake valve is closed. During those valve-closed periods, a certainamount of atomized fuel is sucked into the induction manifold beneath the cylinders and iscarried forward by the airflow through the induction system.

What this means is that a bit of the fuel sprayed by the rear cylinders’ nozzles windup in the middle and front cylinders. Likewise, the middle cylinders “help” thefront cylinders with a bit of their fuel. As a result, the rear cylinders actually get abit less fuel than what their injector nozzles deliver, and the front cylinders actuallyget a bit more!

A few TCM models have top-mounted center-fed induction systems (GTSIO-520s and theIO-550-G, for example), and those engines tend to have much better mixture distribution.But the vast majority of fuel-injected TCM engines use the bottom-mounted rear-fedrunner-and-riser induction system, and all of them exhibit the same characteristicfront/rich, rear/lean mixture maldistribution pattern.

The Solution Is Clear…But Is It Legal?

Once Braly understood the reason for the mixturemaldistribution, the solution was obvious: vary the orifices in the injector nozzles tocompensate for the “borrowing” of fuel between cylinders. The lean-running rearcylinders need larger-orifice injectors that deliver a bit more fuel, while therich-running front cylinders need smaller-orifice injectors that deliver a bit less.

Once Braly understood the reason for the mixturemaldistribution, the solution was obvious: vary the orifices in the injector nozzles tocompensate for the “borrowing” of fuel between cylinders. The lean-running rearcylinders need larger-orifice injectors that deliver a bit more fuel, while therich-running front cylinders need smaller-orifice injectors that deliver a bit less.

Of course, George wasn’t the first to come up with this idea. Knowlegable A&Ps hadbeen quietly playing “musical injectors” on their big-bore TCM engines foryears. I say “quietly” because the use of different-sized injectors on a TCMengine wasn’t exactly legal: the engine’s type certificate data sheet specifies that allinjectors are to be the same size. So this is the sort of thing that mechanics wouldusually do only on their own airplanes, and it usually wouldn’t show up in the logbooks orbe spoken of in public. Generally, this injector swapping was done on a hit-or-miss basiswithout engineering discipline or instrumentation. Sometimes it worked, sometimes not.

Braly started “tweaking” the injectors on the IO-550 engine in hisV-tail Bonanza N11RT (known as “Dragon Lady”), and the results turned out to beimpressive. By the time he finished his experiments, the cylinders reached peak almostsimultaneously (see graph, above right), the engine used around a gallon less fuel perhour (a 7% savings), and the engine ran perceptibly smoother. “This is a goodthing,” George decided.

Braly started “tweaking” the injectors on the IO-550 engine in hisV-tail Bonanza N11RT (known as “Dragon Lady”), and the results turned out to beimpressive. By the time he finished his experiments, the cylinders reached peak almostsimultaneously (see graph, above right), the engine used around a gallon less fuel perhour (a 7% savings), and the engine ran perceptibly smoother. “This is a goodthing,” George decided.

Braly described his injector experiments to some aircraft-owner friends, and they askedif he could make up some “tuned” injectors for their airplanes. Although Georgewas anxious to help his friends out, there were a few problems in doing so:

- The use of different-sized injectors on a TCM engine wasn’t exactly legal, as mentioned previously.

- Although TCM makes a variety of different injector sizes, Braly found significant variations among TCM nozzles stamped with the same size code, and concluded that it would be necessary to re-size and flow-test the nozzles himself. This wasn’t exactly legal, either.

- Using different-sized injectors meant that it was crucial that the correct injector got mated with the correct cylinder, both at installation and anytime the injectors were removed for cleaning or other maintenance.

GAMIjectors Are Born…Painfully

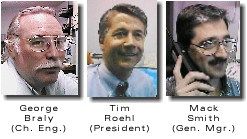

Being an attorney, Bralydecided that if this “balanced injector” business was worth doing, it was worthdoing legally. So George recruited another aeronautical engineer, Tim Roehl, and the twoof them founded General Aviation Modifications, Inc., and applied to the FAA for aSupplementary Type Certificate (STC) to install balanced injectors on TCM engines, and aParts Manufacturing Approval (PMA) to make them.

Being an attorney, Bralydecided that if this “balanced injector” business was worth doing, it was worthdoing legally. So George recruited another aeronautical engineer, Tim Roehl, and the twoof them founded General Aviation Modifications, Inc., and applied to the FAA for aSupplementary Type Certificate (STC) to install balanced injectors on TCM engines, and aParts Manufacturing Approval (PMA) to make them.

Braly and Roehl went through a year of bureaucratic hell in pursuit of their STC. Whatwas supposed to be a simple project wound up involving scores of test flights, thedevelopment of an incredibly elaborate computerized data acquisition system, and theexpenditure of thousands of man-hours and hundreds of thousands of dollars. The storywould make a terrific article by itself (perhaps entitled So YouThink You Want ToGet An STC?) about why technological advances are so few and far between in generalaviation. Had George and Tim known what they were getting into, they probably would havegiven up on the idea.

Ultimately, entrepreneurial tenacity prevailed over bureaucratic red tape, and GAMI wasgranted an STC to install their balanced injectors (dubbed GAMIjectors

The company also received PMA approval to manufacture theirprecisely calibrated sets of matched nozzles. In the process, GAMI had to engineer andbuild a dual flow bench equipped with the most precise pressure and flow measurementequipment to be found anywhere in the aviation industry. The flow rate of each GAMI nozzleis calibrated to a tolerance far tighter than TCM’s “stock” injectors. Eachnozzle is permanently stamped with a unique part number, and each comes with an individualidentification plate that is affixed to the rocker cover of the cylinder. GAMI considersthis necessary to ensure that each injector will go back on the proper cylinder afterhaving been removed for routine cleaning.

The company also received PMA approval to manufacture theirprecisely calibrated sets of matched nozzles. In the process, GAMI had to engineer andbuild a dual flow bench equipped with the most precise pressure and flow measurementequipment to be found anywhere in the aviation industry. The flow rate of each GAMI nozzleis calibrated to a tolerance far tighter than TCM’s “stock” injectors. Eachnozzle is permanently stamped with a unique part number, and each comes with an individualidentification plate that is affixed to the rocker cover of the cylinder. GAMI considersthis necessary to ensure that each injector will go back on the proper cylinder afterhaving been removed for routine cleaning.

As this is being written, GAMI had installed its GAMIjectors

NOTE: For a complete list of engine models for which GAMIjectors are approved, discussion of the approval status for other engines, and answers to other frequently-asked questions about GAMIjectors, see our GAMIjectors FAQ page.

How Much Fuel Do They Save?

Before deciding to install GAMIjectorsTMon my own airplane, I spoke to at least a dozen owners who had flown with them awhile.Everyone reported seeing a reduction in fuel flow of 1 GPH or so (twice that on twins likemine) when the same EGT-based leaning procedure was used before and after the nozzles wereinstalled.

Before deciding to install GAMIjectorsTMon my own airplane, I spoke to at least a dozen owners who had flown with them awhile.Everyone reported seeing a reduction in fuel flow of 1 GPH or so (twice that on twins likemine) when the same EGT-based leaning procedure was used before and after the nozzles wereinstalled.

Many owners also indicated that their engines would now run smoothly even when leanedto 50F or more lean of peak (LOP)! In some cases, the onset of roughness did notoccur until 90F-100F LOP. And by operating 50F lean of peak and increasing manifoldpressure to make up for the horsepower loss at these lean mixtures, the owners reportedfuel savings of as much as 4 GPH (per engine) with no roughness or increase in cylinderhead temperatures. In fact, at these ultra-lean power settings, CHTs were actually coolerthan before.

Is LOP operation safe? It’s not easy to get a definitive answer.

If you look at the various TCM engine operating manuals, you’ll find that TCMspecifically authorizes 50F LOP operation for their IO-550 engines, and for theTSIO-520-BE engine in the Piper Malibu. But LOP operation is not authorizedby TCM for most IO-470, IO-520 and TSIO-520 engines, even though these engines useprecisely the same technology and metallurgy and compression ratios as the IO-550 and theMalibu engine. Why not? Nobody at TCM could (or would) tell us. But common sense wouldseem to dictate that if operating 50F LOP is okay for an IO-550, it’s probably just asokay for an IO-520 or IO-470. After all, an IO-550 is basically just an IO-520 with aquarter-inch longer stroke, and an IO-520 is just an IO-470 with a quarter-inch biggerbore.

Further research reveals that the Pilot Operating Handbooks for some late-modelIO-520-powered Cessnas (including normally-aspirated Cessna 310s) include cruise-powerleaning recommendations with precisely the same wording that TCM uses for the IO-550engine:

At lower power settings, the engine may be continuously operated at any mixture settings from FULLRICH to 27C on the lean side of peak. At higher power settings … the engine should not be operated closer to peak EGT than 20C (rich or lean side). If engine roughness is encountered operating at lower power settings on the lean side of peak, enrichen the mixture slightly for smooth engine operation.

This requires a bit of interpretation. “Lower power settings” seems to meancruise power settings of 65% power or less, while “higher power settings” meanscruise power settings above 65% power. Also, most of us use EGT gauges calibrated indegrees Fahrenheit rather than Celsius. Translating, 27C is roughly 50F and 20C is roughly35F (in round numbers). So in practical terms, this says that at 65% power or less, it’sokay to operate anywhere between about 50F ROP and 50F LOP. At cruise power settings above65%, it’s okay to operate either at 35F-50F ROP or at 35F-50FLOP, but not right at peak.

Of course, when equipped with “stock” nozzles, most TCM engines won’t runsmoothly at 50F LOP, leaving 50F ROP as the only viable option. The ability to runsmoothly in the LOP regime seems to be one of the major benefits of GAMIjectors.Given the choice between operating 50FROP and 50F LOP, there would seem to besignificant advantages to LOP operation. Not only is the engine much more fuel-efficientwhen operating LOP, but the CHTs are also a good deal cooler.

What The Heck’s Going On Here?

Take a close look at the photograph below. This is a the panel of a Cessna 414 inflight. Both engines are equipped with turboGAMIjectorsand both are operating at the same cruise power. EGTs and TITs are approximately the samefor both engines, are is engine RPM. Yet the left engine is consuming 3.2 GPH less fuelthan the right engine. At the same time, the left engine has CHTs that are between 25F and50F lower than the right engine.

QUESTION: What the heck’s going on here?

ANSWER: The right engine of this airplane has been leaned to 50F rich-of-peak,while the left engine has been leaned to 50F lean-of-peak. Since leaning from 50FROPto 50FLOP results in approximately a 10% loss of engine horsepower, the left enginepower was restored by increasing the manifold pressure by about 3 inches.

Most of the pilots and so-called “engine experts” I’ve talked to look at thisphoto with disbelief because they expect that the engine that is leaned more aggressivelyshould run hotter. But they’re dead wrong! It turns out that at any particular powersetting, maximum CHT occurs at around 35F ROP, and than either enrichening orleaning from that point causes CHTs to go down! This is precisely what engine theorypredicts, and precisely what the mixture-vs-temperature graph in the TCM engine operatingmanual shows.

How the widespread misconception arose that “leaner is hotter” is beyond me.The fact is 50F ROP (where most people operate) is very close to the maximum CHT point.Leaning further to peak EGT actually causes CHTs to come down a little, andcontinuing to lean to 50F LOP makes them come down sharply. The instrument readings in thephoto above clearly demonstrate this to be true.

You could achieve the same kind of CHT reduction by operating ROP, but todo so you’d have to run so rich (around 200F ROP) that your fuel flows would go to themoon and your engine would become quickly contaminated from unburned combustion byproductsresulting from the excess fuel.

Reports From The Field

Plenty of GAMIjector users have been experimenting with 50F LOP operationand seem to be having good results. George Braly has been operating his Bonanza”Dragon Lady” that way for nearly two years now, and more and more GAMIjectorusers are starting to follow his lead.

My friend Dr. Brent Blue from Jackson Hole, Wyoming, wrote me the following commentsafter installing turboGAMIjectors in his Cessna340 twin:

I put them on in mid-March and have flown about 15 hours with them so far. Probably the most significant difference is that I have gone from 35-36 GPH to 30-31 GPH with no change in TAS, and the CHTs run 25-50F cooler. This allows me to make several of my one-stop trips into non-stop ones. For instance, I often fly from Jackson Hole to the Chicago area. In the absence of strong tailwinds, I used to have to make a refueling stop in order to get to PWK or UGN with IFR reserves; I can now make the trip non-stop. In addition to saving me $10/hour in avgas, I can forsee significant savings in landing/takeoff cycles, tires, brakes, starters, etc. It’s like having an extra tank with an hour’s worth of free fuel!

Prior to the GAMIjectors I would lean to 50F ROP or 1600F TIT, whichever came first. With the GAMIs, I lean at 30″ MP and 2300 RPM to 50F LOP, then increase the MP to 32.5″ to make up for the power loss. At that setting, TITs run between 1590F and 1610F, and I’m using 5 GPH less than before.

Basically, I love them!

And from Walter Atkinson, who flies a normally-aspirated Bonanza based in Baton Rouge,Louisiana:

My wife and I recently flew from Baton Rouge to Vail, Colorado. At my 175 knot cruise speed, BTR to EGE is 6 hours non-stop. With the GAMIjectors I got there with 2.5 hours of fuel remaining. Wow, what a safety factor! I’m starting to wonder if I’ll have to start buying Preparation H by the case for those 1200 NM non-stop trips?

I recently flew to Okmulgee, Oklahoma, and back in formation with another Bonanza. He burned 14.9 GPH at 50F ROP (GAMI-less), while I burned 12.9 GPH at 50F LOP (with the GAMIs). Obviously, we were going the exact same speed since I was within 25 to 50 feet of his wing the whole trip. His CHTs were a warm 375F, while mine were 300F on the left bank of cylinders and 275F on the right bank. Damn, I like the way those GAMIjectors work.

Less Vibration, Too

MostGAMIjector users I spoke with also reported that their engines ranperceptibly smoother with the new nozzles. GAMI says they have received at least 100letters from customers that report the same thing. The comments of Allen Wolpert (whoflies a Beech B36TC out of White Plains, New York) are typical:

MostGAMIjector users I spoke with also reported that their engines ranperceptibly smoother with the new nozzles. GAMI says they have received at least 100letters from customers that report the same thing. The comments of Allen Wolpert (whoflies a Beech B36TC out of White Plains, New York) are typical:

From the moment I started the engine on runup it was clear something was different. My engine was always very smooth at idle and I have the Capehart cam that lets it idle nicely. But the engine felt even smoother. And normally at idle the GEM display is a bit ragged. This time all the EGTs were lined up. As I ran the power up to between 800 and 1700 RPM all the cylinder bars would move in lock-step up and down.

From the moment I started the engine on runup it was clear something was different. My engine was always very smooth at idle and I have the Capehart cam that lets it idle nicely. But the engine felt even smoother. And normally at idle the GEM display is a bit ragged. This time all the EGTs were lined up. As I ran the power up to between 800 and 1700 RPM all the cylinder bars would move in lock-step up and down.

Before installing the turboGAMIjectors I had done a test to see the sequence in which my cylinders reached peak EGT. Cylinder #2 was the first to peak at about 15 GPH, and there was about a 1.8 GPH “spread” before the last cylinder reached peak. During this test, the engine would run rougher and rougher as I leaned, to the point where I felt compelled to rapidly enrichen the mixture as soon as the test was over.

With the turboGAMI’s I started leaning to 50F rich-of-peak at 16 GPH, then kept on leaning past peak to 50F lean-of-peak at 13 GPH. TITrose from 1580 at 15GPH to 1620 at peak EGT and then fell to about 1550 at 13 GPH. During the leaning cycle, there was no change in engine smoothness. I cycled the mixture from 50F rich-of-peak to 50F lean-of-peak looking for any change and I couldn’t feel a thing. Running 50F LOP at 13 GPH was as smooth as 50F ROP at 16 GPH, but TIT and CHT were both cooler at the LOP setting.

These subjective reports were confirmed recently when Chadwick-Helmuth spent severaldays running tests on a 1993 Beech F33A instrumented with one of C-H’s lateststate-of-the-art vibration analyzers hooked to multiple accelerometers and vibrationtransducers. Tests were flown at a wide range of power settings and mixtures using a setof standard TCM nozzles, then repeated after GAMIjectors were installed. Theresults indicated that the GAMIjectors reduced vibration levels at the 2ndorder frequency and at the low 1/3rd order frequency by 60% to 80%.

My Own turboGAMIjector Experience

I installed a set of turboGAMIjectorson my 1979 Cessna T310R during the most recent annual inspection. It had been mylong-standing practice to operate this aircraft between 60% and 65% cruise power, leanedright to peak EGT.

I installed a set of turboGAMIjectorson my 1979 Cessna T310R during the most recent annual inspection. It had been mylong-standing practice to operate this aircraft between 60% and 65% cruise power, leanedright to peak EGT.

One very odd thing about my airplane is that the left engine has always used about 8pounds per hour (1.3 GPH) more than the right engine when both operated at the same powersetting and leaned to peak EGT. It was like this when I first bought the airplane in 1987.At first, I drove myself crazy trying to find the reason for the fuel flow split, but withno success. Then in 1990, I had both engines majored. But the freshly overhauled enginesexhibited the same 8 PPH fuel flow split as before. I confirmed that this was a realdifference in fuel flow, not a gauge problem. And I’ve been living with this mystery forten years now.

On my first test flight after installing the turboGAMIjectors,I was amazed to discover that this mysterious fuel flow split had almost completelyvanished! With both engines leaned to peak EGT, the fuel flow needles are now almostmatched up…perhaps a 2 PPH difference at most. I still don’t know what caused the split,but the GAMIs solved it.

Leaning to peak at 65% power, my left engine fuel flow has dropped from 90 PPH (15 GPH)to 80 PPH (13.3 GPH), while my right engine fuel flow dropped from 82 PPH (13.7 GPH) to 78PPH (13.0 GPH). The total savings is about 14 PPH or 2.3 GPH, and that’s with no change inleaning procedure (i.e., not operating LOP).

The engines do seem to run a bit smoother, too, since the nozzletransplant. I hasten to add that this is just my subjective reaction, and not based on anyactual vibration analysis. The airplane has always run well; it just seems to be running abit better now.

In the meantime, based on my own experience and the cross-section of other owners I’vetalked to, I can recommend GAMIjectors to any fuel-injected TCM engine ownerwithout reservation. A set of six GAMIjectors costs $799.00 (for turbos,$949.00) and should pay for itself in a few hundred hours just in fuel savings alone.(Even sooner if you start operating lean-of-peak after the nozzles are installed.) Theadded range, reduced vibration and cooler engine temperatures are just frosting on thecake. Your engine will run better!

The folks at GAMI – George Braly,

The folks at GAMI – George Braly,