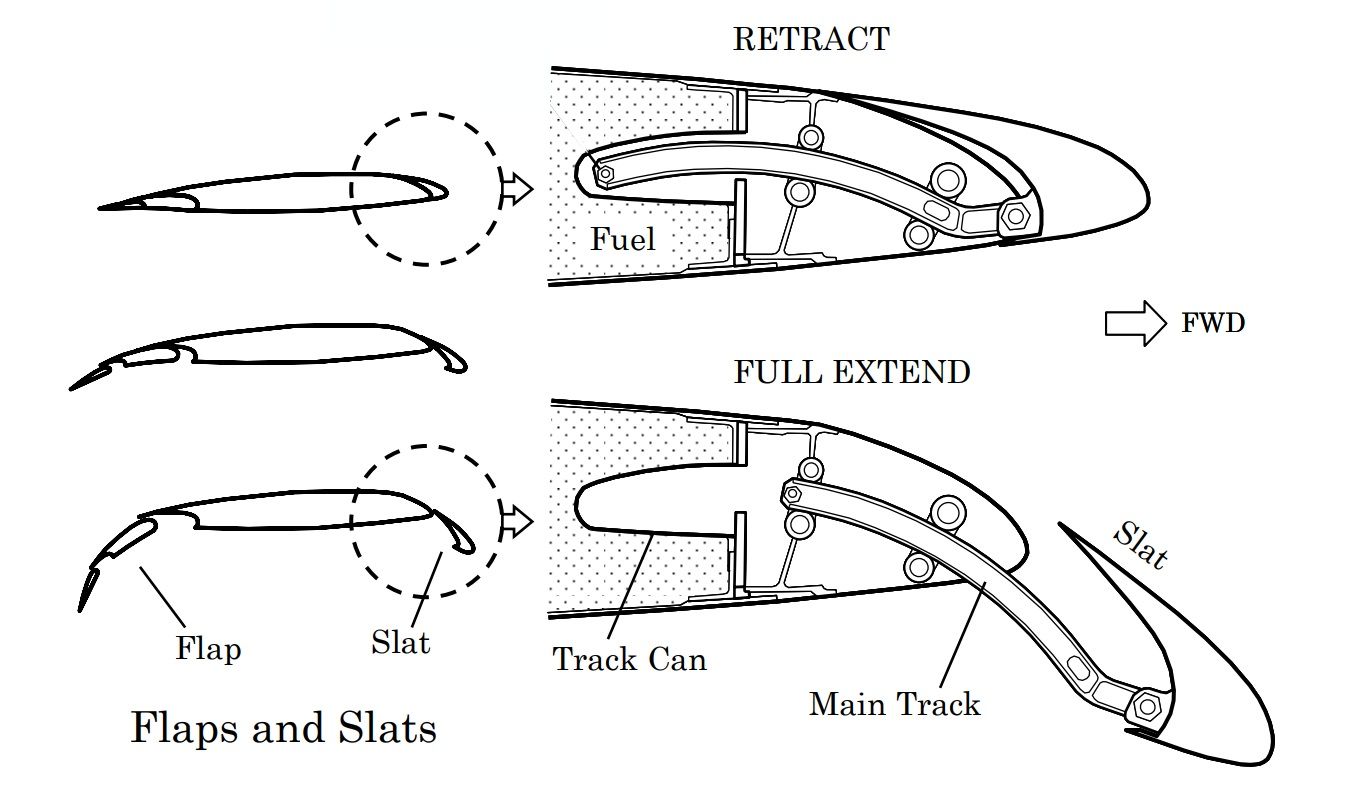

The FAA is proposing a $5.4 million civil penalty against Boeing in addition to the $3.9 million fine it’s already sought for the use of faulty slat tracks in two models of the 737. The $3.9 million fine, levied for the inclusion of the faulty parts in 133 NG models, was proposed in December. On Friday, the agency proposed the $5.4 million penalty for the use of the nonconforming parts in 178 737 MAX aircraft. In a news release, the FAA alleges Boeing “knowingly submitted aircraft for final FAA airworthiness certification after determining that the parts could not be used due to a failed strength test.”

The tracks are made of metal that was determined to have been weakened during the manufacturing process by the excess presence of hydrogen in a condition known as “hydrogen embrittlement.” The FAA says the quality issues were first flagged in July of 2018 but that Boeing continued to submit, as airworthy, aircraft with the affected slats for certification until March of 2019. “The FAA alleges that Boeing failed in this instance to maintain its quality system to ensure suppliers adhered to Federal Aviation Regulations,” the news release said. The company has 30 days to comment on the proposed penalty and issued a statement to simpleflying.com saying it’s aware of the penalty and is working with the owners of the aircraft to replace the parts.

Ever since the slat story broke, I’ve been opining that this is a much bigger issue than the MCAS fiasco.

MCAS was incompetence. This is willful treachery.

I won’t get into the willful treachery comment but it sure does demonstrate the results of having financial people in charge of an engineering and production company. Further, it clearly demonstrates the conditions created by today’s middle and upper management attitudes. Don’t tell me bad stuff, only tell me good stuff so I can get promoted again.

I wholly agree that this is the result of financial people in charge of the company. Profits may have been up, but manufacturing design and quality have obviously gone way down. As far as I’m concerned, the whole board should be shaken up, and any upper managers who knew or suspected such activity was going on should be fired without severance.

I feel the same. I’m not comforted knowing that that team is still holding the reigns after what it did and putting my life at stake for profits. I will feel safer when they go and we have aviation folks represented at the highest decision making. Until then, let them fly their families in this planes and it might help reminding trust.

Completely right David C.

This is reckless and CRIMINAL. Managers and mechanics should go to jail. Remember Nazis said they were following orders. That excuse was rightfully rejected at Neuremburg Trials. Even little people who speed must pay the fine. These people knowingly put others lives in jeopardy for the sake of their jobs. NOT ACCEPTABLE. The murderer Mulenburger now walks with more than $60 million for his handy work.

9 months of noncompliant parts still in the mfg pipeline? I suspect some management f*ck or f*cks were trying to maintain favorable production reports and/or schedules.

In my experience hydrogen embrittlement does not sneak up on you. The potential for it is known and well-understood, and highly effective methods for dealing with the issue are always in place as part of the manufacturing process. Shortcuts and cutting corners, for whatever reasons, are the likely causes of bad parts being installed on airframes here.

The Max is already a bone pile so how does it work to fine Boeing after Bankruptcy has been filed?

Did Boeing file for bankruptcy protection?

Somehow, I missed that story. When did it happen?

I cannot verify it. I heard it on the news. Could have been mentioned as an option. It would be no surprise considering the liability involved. I know I won’t take a flight on one.

Fake News.

Boeing has NOT filed for bankruptcy protection, nor will they.