McFarlane Aviation, which provides a host of replacement parts for Cessna aircraft, has released Service Bulletin SB-10, Revision A, warning that there might be “material defects” in the extruded-aluminum hinges the company sells for Cessna ailerons. These defects could lead to cracking of the hinge. McFarlane says the hinges were produced between Feb. 22, 2019, and Jan. 2, 2020, and isolated to job lots JO55493, JO55519, JO56823, JO57775 and JO60003. (The number is stamped on the part.)

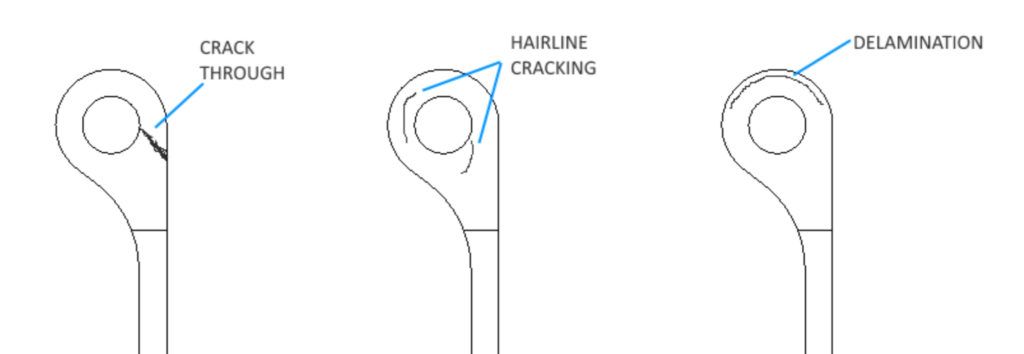

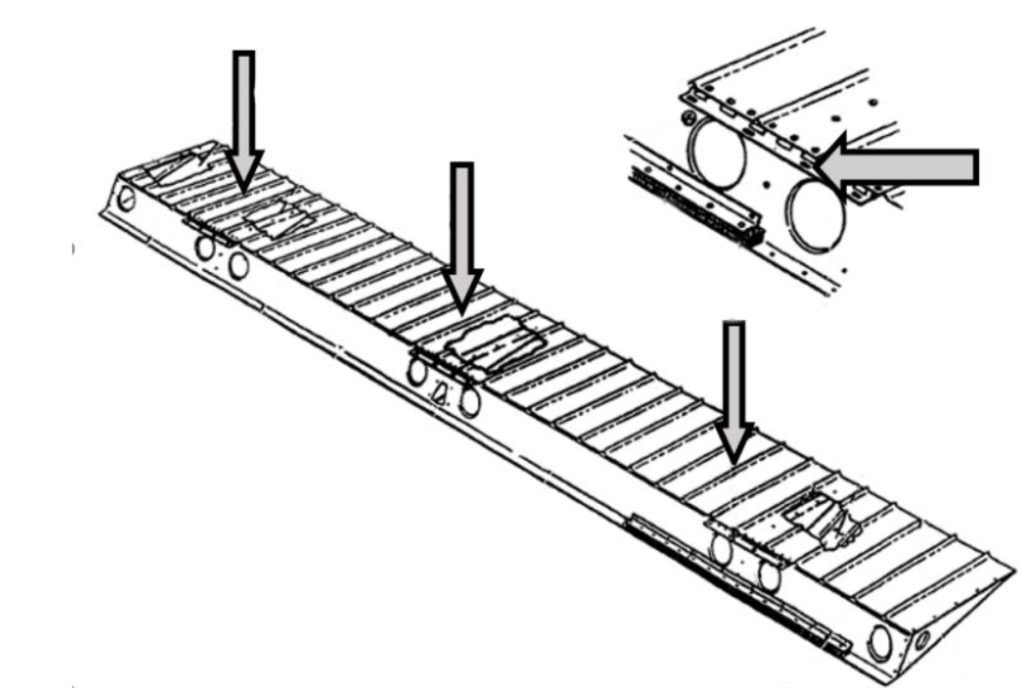

According to the company, “Disassembly and inspection of the McFarlane aileron hinge is mandatory and must be completed within the next 25 hours time-in-service (TIS) after February 7, 2020, or within the next 6 months after February 7, 2020, whichever comes first if the aileron hinge is one of the lots listed in section IV of this service bulletin. If the inspection identifies extrusion cracks or delamination of the hinge bulb, immediate replacement of the hinge is required prior to further flight.”

Inspection requires removal of the hinge pins and partial separation of the control surface from the airplane. A 10X magnifier can be used to detect the cracks. McFarlane is crediting customers with $50 for each aileron inspected and another $40 per aileron hinge for replacement of cracked parts.

How much will this defective McFarlane hinge replacement REALLY cost the owner?

304 stainless weighs three times as much as 6061 or 7075 aluminum. BUT, a stainless hinge can be fabricated with less than half of the material thickness of the extruded hinge, so…

If you’re paranoid about the knuckles opening up, just dip braze them shut. Passivate. Done. And the fabrication cost is about one-tenth that of the extruded design.

“Not everything that CAN be done, SHOULD be done.”