Wisconsin-based Engineered Propulsion Systems Inc. (EPS) is back at AirVenture to announce progress on its clean-sheet diesel design intended to go up against established versions from Austro Engine and Continental. Next step for EPS includes more testing, advancement toward certification–and, as always, the hunt for more funding.

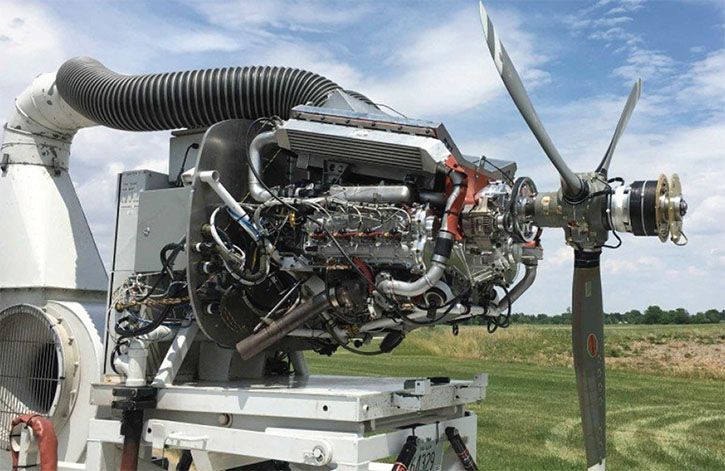

EPS is tackling the daunting diesel challenge from a different direction—creating a clean-sheet aviation design, not an auto conversion—of a horizontally opposed configuration they’re calling a “Flat Vee.” They’re confident enough in their design to project a 3,000-hour time-between-overhaul, not time-between-replacement, a serious diesel sticking point.

“We are not a TBR engine,” the EPS team likes to point out, achieving that goal with advanced steel alloy components including a steel crankcase and steel pistons. The EPS engine will come with a single-lever FADEC and unique mechanical and electronic vibration control features.

AVweb interviewed EPS co-founders Michael Fuchs and Steven Weinzierl to catch up on what looks like an intriguing project.You can listen to their comments here. To advance toward certification, the team needs to complete software development, finalize airborne electronics hardware, finish documentation and work on environmental testing, among other items.

Fuchs and Weinzierl come to the project as engine development pros, with Dick Rutan serving in a flight test role. First flight of the EPS proof of concept was aboard an SR-22 with Rutan at the controls. The team is eyeing the refurb market and believe the EPS diesel’s superior fuel economy and resulting endurance will drive sales.

For more information about the EPS diesel, visit www.eps.aero.