Leveraging its expertise in military and commercial jet engines, GE’s business aircraft engine division has announced a new turboprop engine in the 850- to 1650-HP range that will compete with the market-dominating Pratt & Whitney PT6 series. The new engine, which GE calls the Advanced Turboprop engine, has already found a launch customer in Textron’s just-announced single-engine turboprop, a 12-passenger aircraft that enters a market already crowded with choices.

In announcing the ATP at the NBAA convention in Las Vegas Monday, GE’s Brad Mottier said that the ATP’s advanced technology will allow the engine to produce up to 10 percent more horsepower on 15 percent less fuel consumption than competitive engines in the class. Furthermore, it will feature electronic engine controls that will improve efficiency, provide exceedance protection and allow single-lever operation, as with a jet engine. Development on the new powerplant began five years ago, shortly after GE purchased the Czech Republic-based Walter Aircraft Engine Company with the intent of entering the commercial turboprop business. GE is already the market leader in commercial jet aircraft engines.

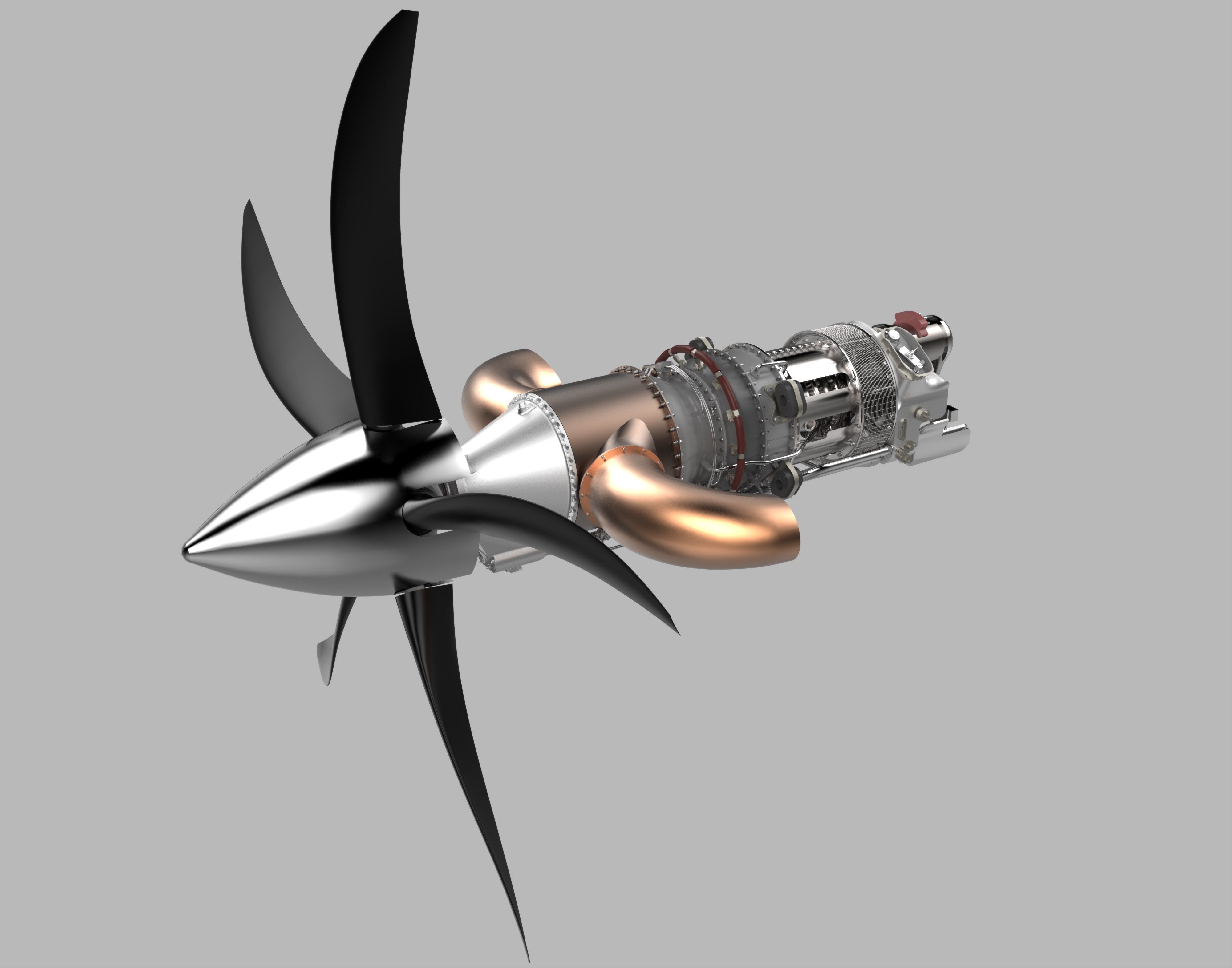

And it will be using that expertise to manufacture the ATP with such military-adapted technology as 3D aerodynamic turbine blades and variable stator blades. The engine will have four axial stages, one centrifugal stage with two high-pressure turbines and one low-pressure turbine, a spool build up that Mottier said has never been attempted in a turboprop of this class. Mottier said the ATP will have a 16-to-1 pressure ratio, nearly double that of typical turboprops currently on the market. Using cooling technology developed for its military engines, the ATP will run at higher temperatures than typical turboprops, which increases thermodynamic efficiency.It will weigh about 535 pounds and will be about the same length as an equivalent PT6, albeit at a slightly smaller diameter. Mottier said this will make the engine suitable for retrofits. The ATP will be manufactured in Europe, where GE will invest some $400 million in new manufacturing facilities.

The engine has not been assembled or operated yet, but GE said it plans to provide Textron with a test article in the 2017 to 2018 time frame. Since it bought Walter, GE has expanded the turboprop business from under $100 million to an expected $1 billion by 2020. The company’s current offerings, the H-series engines based on Walter’s original M601, are finding application in the retrofit market.