Indonesian investigators said Wednesday that a faulty angle-of-attack indicator on a Lion Air Boeing 737 MAX 8 wasn’t replaced or repaired prior to the Oct. 29 crash into the Java Sea that killed all 189 people aboard. In a preliminary report on the accident, Indonesia’s National Transportation Safety Committee said the aircraft was unairworthy and should have been grounded.

Although the initial report doesn’t assign definitive cause to the accident, the NTSC was blunt about the airline’s maintenance: “In our opinion, the plane was no longer airworthy and it should not have continued,” Nurcahyo Utomo, the NTSC’s aviation lead, told reporters at a press briefing on Wednesday in Indonesia.

The report revealed that the aircraft, a 737 MAX 8 with only 800 hours on the airframe, experienced an angle-of-attack indicator disagree between the left and right side on the previous day’s flight into Jakarta. The crew disabled the aircraft’s electric stabilizer trim and continued the flight, with the first officer flying on what the crew deemed to be more reliable instruments.

Although the crew appears to have squawked the problem, the NTSC reports that maintenance was done on other components, but apparently not the AoA sensor, although press reports differ on this finding. The airplane had a history of unreliable airspeed and AoA indications, but the report doesn’t detail whether these were due to faulty maintenance or defective components.

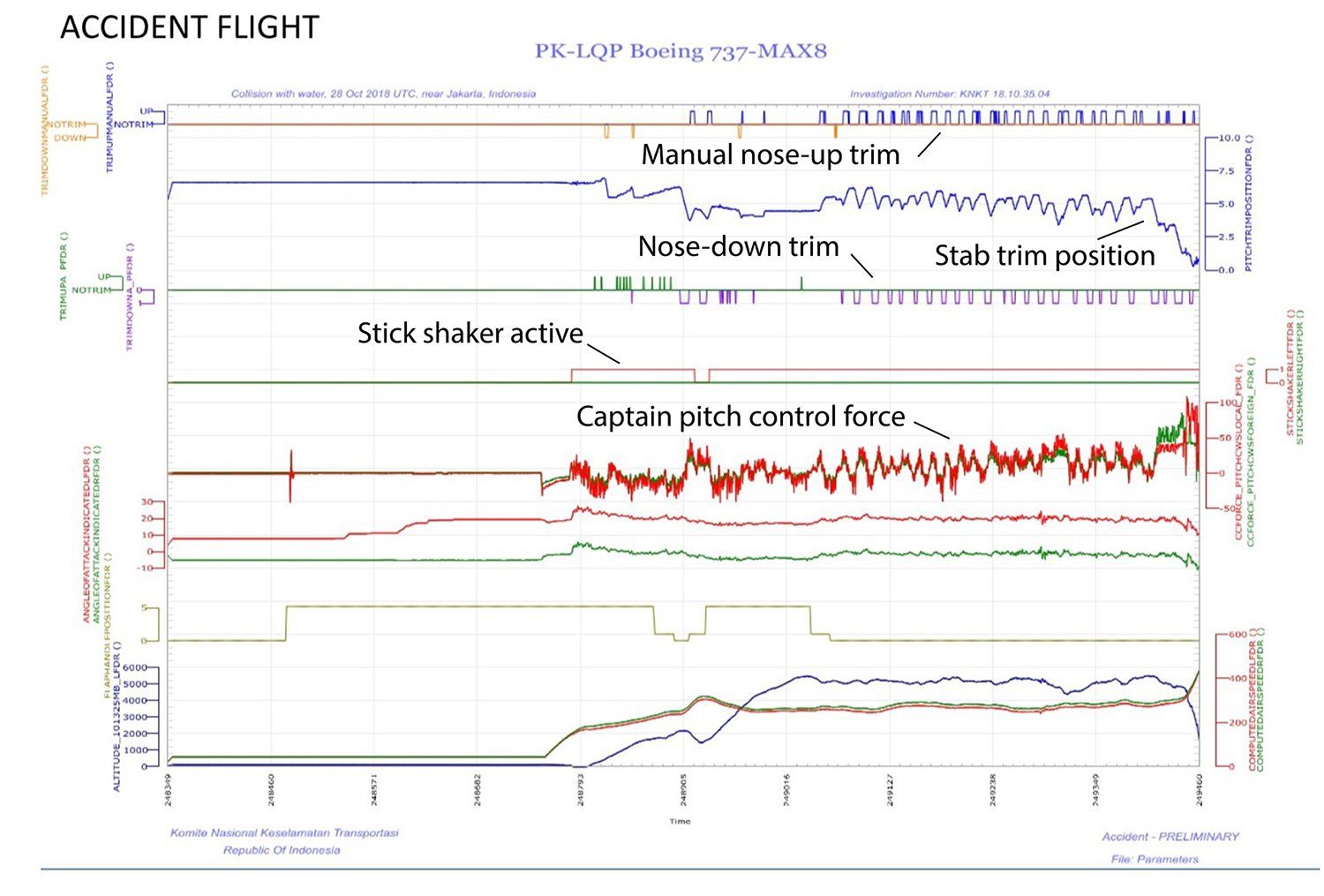

While NTSC awaits the arrival of a specialized ship to continue its search for the aircraft’s cockpit voice recorder, data from the recovered flight data recorder revealed that the pilots struggled to maintain consistent pitch, speed and altitude throughout the 11-minute accident flight. The data trace released by the safety agency showed that faulty AoA indications activated the left-side stick shaker almost continuously shortly after takeoff.

The faulty AoA indication also invoked an automatic background trim system Boeing installed on the MAX series called MCAS, for maneuvering characteristics augmentation system, according to the FDR data. Because the MAX aircraft have heavier engines, the center of gravity is biased more forward than on previous models and MCAS is intended to improve pitch feel and provide stall protection. It activates automatically in manual, flaps-up flight at high angles of attack and high load factors, adding nose-down stabilizer trim at a rate of 0.27 degrees per second to a maximum of 2.5 degrees. MCAS will continue to add nose-down trim until the high AoA is resolved.

The system can be temporarily defeated by trimming against it using the yoke-mounted trim switches. But it will resume nose-down trimming after five seconds. The 737 series is equipped with stabilizer trim cutout switches and if activated, the airplane’s electric stabilizer trim is disabled, which also disables MCAS.

The crew that experienced similar problems on the previous day’s flight did use the trim cutout switches, the NTSC said. Because the CVR hasn’t been found, it’s unclear why the accident crew didn’t do the same. “We need to know what was the pilot discussion during the flight. What was the problem that may [be] heard on the CVR. So why the action difference, this is the thing we need to find. At the moment I don’t have the answer,” said the NTSC’s Utomo.

Released flight data shows that flight JT610 flew an inconsistent flight path characterized by pitch, altitude and vertical speed excursions. The captain’s stick shaker activated shortly after takeoff and remained almost continuously active. The captain appears to have used manual nose-up electric trim against MCAS’s nose-down trim at least 30 times, according to the FDR data. Nose-down yoke forces appeared to have peaked at just over 100 pounds.

Although it’s not implicated as a crash cause, pilot unions in the U.S. have complained that Boeing provided no detailed documentation on MCAS and the system wasn’t covered in differences training for crews transitioning from earlier 737 models. Shortly after the Lion Air crash, the FAA published an emergency AD (PDF) detailing potential fault indications in the AoA, airspeed and control feel systems used on the 737 MAX. Boeing said existing runaway trim procedures—essentially using the stabilizer trim cutouts—could address these problems. The 737 still retains manual trim control wheels, a relative rarity in modern airliners.

In a statement, Boeing said it’s taking every measure to fully understand all aspects of the accident and continues to maintain that the 737 MAX 8 is a safe aircraft.