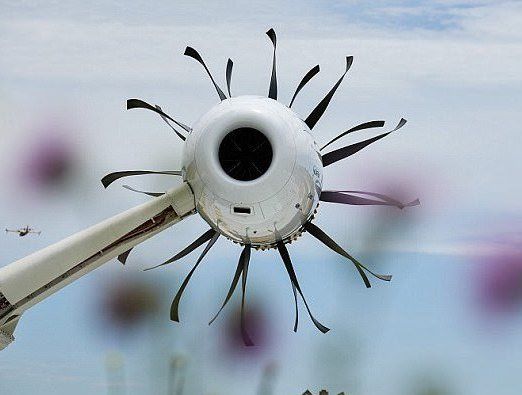

Safran, the French multinational aerospace and technology firm, celebrated the start of ground testing for its Open Rotor concept engine earlier this week. The Open Rotor is a variation on the propfan or unducted fan concept where a turbine engine drives one or more external fans. The Open Rotor utilizes two counter-rotating, unshrouded fans, which, like a turboprop, increases the effective bypass ratio of the engine. The European Commission, as part of the Clean Sky 2 research program, has given Safran €65 million over eight years to develop the fuel-efficient engine. “After ten years of development efforts, we are very proud to see the Open Rotor demonstrator perform its first ground tests with success,” said Clara de la Torre from the European Commission. “The Open Rotor marks a major step forward in the aviation sector, since it meets two key challenges, namely to reduce fuel consumption and improve environmental performance.”

Prior attempts at unducted fan designs have struggled with extremely high cabin noise levels from the unshrouded fan tips. Safran R&D director Stphan Cueille says they’ve solved that problem: “Our demonstrator has the same sound levels as [the LEAP turbofan], thanks to an optimization of the aerodynamics of fan blades.” The company hopes to have a certified engine ready to market by 2030. Ground testing on the current engine will continue until at least the end of the year at Safran’s new 864,000-square-foot open air test facility in Istres, France, says the company.

“The Open Rotor is a major focus of Safran’s research,” said Philippe Petitcolin, CEO of Safran. “With the LEAP engine, we proved our ability to develop and integrate new technologies. Our aim now is to push our innovation strategy even further so we can deliver the best solutions to the market in timely fashion. We are currently studying several paths, both different and complementary, to develop, along with our partners in Clean Sky, the technology building blocks for propulsion systems that will significantly improve performance on tomorrow’s airplanes.” The LEAP turbofan is produced as a joint venture with GE.