There’s so much buzz around the emergence of electric airplanes that it’s easy to forget what animates most of the enterprise is press releases. New airplane announcements fly fast and furious; the airplanes themselves, not so much. Cutting through this background noise is the innovative Slovenian company, Pipistrel. In 2020, as it promised it would, it announced the first certified electric airplane, the Velis Electro. The word “certified” here shouldn’t be taken to suggest the Velis is a Part 23 airplane in the way that a Diamond DA20 or 40 or a Cirrus SR22 is. Yes, the Velis is a standard category airplane, but certified to CS-LSA at the 600-kg (1320-pound) limit. We would know this as an S-LSA in the U.S. with all the limitations that LSAs have, including day VFR-only approval and limited useful load.

I was given unusual access to a new Velis in the flight test regime by Isaac Silver and Brian Kish at Florida Institute of Technology (aka Florida Tech) at the school’s Melbourne, Florida, location. FT bought a new Velis with a grant from the Emil Buehler Perpetual Trust endowed to the school.

The institution has a long history of working with the FAA on research projects outside the agency’s normal purview and that’s what they’re doing with the Velis, wringing it out to feed the FAA enough data points to develop a framework for Part 23 certification. No one should assume those guidelines are imminent because they are anything but. The same probably applies to expanded consensus standards for electric airplanes.

Whether this matters for the Velis is debatable. Silver describes it as a well-executed, mature electric power train that’s a considerable leap beyond what went before it in the Alpha Electro and an airplane that’s probably been taken as far as anything electric can be for the moment.

Unfortunately, that’s not very far. With its 22 kWh battery system, the Velis is essentially a 40- to 50-minute airplane and allowing for the U.S. required endurance reserve, that’s a 20-minute flight time. And that may be pushing it at gross weight. Thus far in the U.S. and probably forever, there is no dispensation from the 30-minute VFR minimum fuel requirement, including experimentals, which approval the Velis flies under in the U.S. (The Velis POH performance section allows for a 10-minute reserve.) While the Velis is finding buyers in Europe, I suspect this is the early adopter market. With its short legs, it’s hard to see how the Velis fits into the U.S. market as anything but a technology demonstrator, albeit a refined one.

Third Gen

Thanks to Pipistrel founder Ivo Boscarol’s unswerving dedication to low-emission transportation and electric flight, the company has been at the electric airplane game longer than any others we know of. It pioneered an electric motor glider called the Taurus, introduced in 2011, and although it hasn’t sold many, that served as a stepping stone for a proof-of-concept electric airplane called the WATTSUp in 2014 followed by a production airplane, the Alpha Electro.

Pipistrel has found success with its light, composite two-seat aircraft, especially in the European market. A trainer version, the Rotax-powered Alpha Trainer, is a strong seller for Pipistrel. In the Alpha Electro, Pipistrel learned enough about batteries, inverters and motors to understand that (a) total battery capacity is (and remains) a significant limitation and (b) so is keeping the batteries healthy enough to deliver rated capacity. Here, the Velis Electro jumps ahead, with an improved battery system and water cooling to keep them thermally stable.

For all their seemingly miraculous ability to store watts and watts of power, lithium-ion cells don’t store much when compared to gasoline—the ratio remains about 100 to 1 in favor of hydrocarbon fuels, if not more. Just as hobbling is that lithium-ion batteries don’t like high discharge rates and fast charging. The former is as inevitable as the latter is desirable because who wants to wait around an hour just to go flying for another hour?

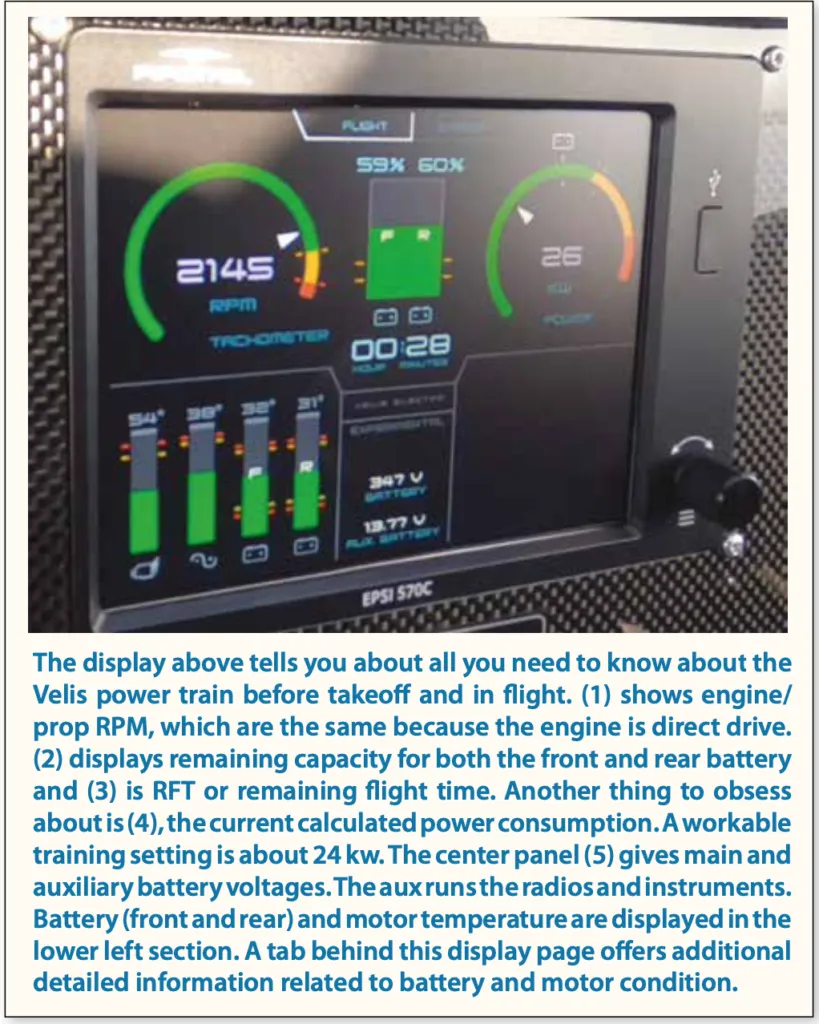

As lithium batteries age, they lose their ability to deliver rated energy and even though charged to an indicated 100 percent, they may be capable of delivering considerably less total power capacity than expected. This is not always predictable so Pipistrel has exerted a lot of effort in sensors and software to track aging-related capacity reduction. Both state of charge and state of health are displayed for the pilot.

Battery aging has proven to be a nuisance in electric cars but is obviously more serious in electric airplanes because judging endurance then becomes a moving target. In the Velis, below 15 percent capacity, the battery management system, to protect the cells, simply disconnects the pack and leaves you to shift for yourself. Further, the software is festooned with warnings, one of which advises the pilot that there’s not enough power remaining to execute a go-around, so … sorry, like it or not you’re landing.

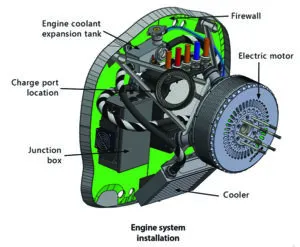

Systems

Like the Electro, the Velis builds on previous airframes, specifically the Virus SW 121, an EASA type-certified airplane. The two actually share the same type certificate. Showing its glider DNA, it has a high-aspect-ratio cantilevered wing with full-span flaperons and a conventional T-tail that’s high enough to require a ladder for topside inspection.

The structure is carbon, glass and aramid fiber built with a wet layup system. The landing gear is a composite leaf structure equipped with smallish 4.00-6 tires and Beringer brakes. Silver said he found significant wear on the tires after only a dozen hours of operation. If the Velis finds a niche as a landing cycle trainer, this could be a wear point. Unusual for an LSA, the nosewheel is steerable, thus the Velis handles precisely on the ground.

Glasswork and paint on the Velis are superb with all the gaps neatly sealed with gap tape. The wings are equipped with quick disconnect hardware, although we doubt it would be desirable to trailer it much. In any case, it shouldn’t be stored outside in the weather because the electrical connectors—of which there are quite a few—are not sufficiently weatherproof. And with voltages nearing 400 at 120 amps, this is not a trivial consideration.

The leap forward for the Velis is water cooling for the batteries and also for the motor. This was done to provide thermal stability for both discharge and charging, which promotes—at least it’s hoped—better battery durability. The system is similar to an automotive coolant circuit with pumps, a filler nozzle, radiators and, of course, antifreeze.

There are two battery packs, one forward between the engine and the cabin and one aft where the Alpha normally has a small baggage area. FT weighed the packs at 73.7 kg or 162 pounds each. They are removable with effort, but aren’t quick change packs, as Pipistrel once considered but rejected. A separate 12-volt battery charged through a DC/DC converter powers the instruments and avionics.

There’s a fair amount of coolant, 1.4 gallons (5.4 liters) for the batteries and about a quart for the motor. Coolant operation is automatic and monitored on a cockpit display. The cooling system automatically activates when the aircraft is plugged in for ground charging.

Pipistrel uses Samsung INR18650 cylindrical cells popular for laptops and power tools. Designers of electric vehicles face an antagonistic challenge. Batteries that are thermally stable and have low risk of fire aren’t necessarily the same ones that will tolerate rapid discharge under takeoff and climb power and/or rapid recharge when nearly depleted.

Then there’s the question of energy density. Electric car batteries—notably the 2170 cylindrical cells that Tesla uses—have a claimed density of 265 watt-hours per kg (wh/kg), but throw in the pack structure, the cooling and sophisticated battery management system and the effective energy density is a lot less—about 160 wh/kg for Tesla. Depending on how you parse the Velis capacity, it appears to be between about 149 and 168 wh/kg as measured by FT. Pipistrel’s data rounds the capacity down to 11 kWh, although the nominal maximum is 24.8 kWh.

At the lower value and with a 65-kw (87-HP) motor—Pipistrel calls it an engine—the math is pretty simple: You can’t run the engine at full power or even high power and expect to have much endurance. The POH offers extensive mission planning to maximize the airplane’s endurance limits.

Range And Endurance

In a word, well, two words: not much. To begin with, the engine is limited to 90 seconds of maximum takeoff power, for both durability and power consumption reasons. Because the engine has terrific torque (220 Nm peak), that turns out to not be not much of an issue, but for a primary trainer, it’s maybe a bit much.

While the airplane accelerates and climbs well, it requires flaps for takeoff so the newbie pilot is confronted with reducing power and flap retraction right after takeoff, all the while monitoring the power instrument. While that’s doable, Silver said he thought it wouldn’t prove desirable for U.S.-style training in which Cessna 172s and Piper Archers can pound out full power all day and are, in the end, simpler to operate.

Following our short flight, Silver asked if I felt the range anxiety Tesla owners are quite familiar with. I surely did. When the power goes to full—it was a notch over 65 kw indicated—the displayed endurance drops like a stone, hence pulling the power back. And at gross weight—electric airplanes appear to be quite sensitive to weight swings, Silver says—you’re not going much above 1500 feet and you don’t want to get far from a runway, either.

One surprise is how much punch all that torque delivers because it comes on all at once. Silver told me I did what everyone who flies the airplane has done: a slight leftward drift and a right roll to correct. Ninety seconds comes quick and after the power is reduced and the flaps retracted, the airplane climbs well enough—just not very high. We had only a few minutes to hustle to the practice area, try a few turns and cruise settings and then head back to the airport to meet the legal reserve requirement. And you’re advised to pick an upwind practice area if one is available, just in case.

For a typical training speed—85 knots would be on the slow side—we were burning 22 to 24 kw after reaching the practice area. Even at that, the RFT indicator—remaining flight time—was down to 36 minutes. Flying straight back, we would land with just 30 minutes remaining or a little less, so I pulled the power back more.

There was no time for any maneuvering, just a few quick power checks and some turns. The Velis handles well enough and the visibility outside is spectacular, thanks to the clear plastic doors. Despite its quirks, it is fun to fly. But Isaac Silver is right. Pilots training in this airplane might be distracted by the constant worry over power remaining and probably for no particular advantage over a Rotax-powered airplane, at least for now. Five years hence? We’ll see.

A Trainer? Barely

After we landed and recharged the airplane we had used 12.6 kWh for a 21-minute flight. That means despite what the RFT said, we had a little less than that remaining so we landed under the 30-minute requirement. (The RFT attempts absolute truth and doesn’t build in a calculation for the 15 percent turn-into-a-pumpkin battery cutoff.)

Recharging took an hour and 20 minutes, although a fast charge setting can do it quicker. This brings up another wart: Hangars will need 220-volt high-amp service and many in the U.S. don’t have it. Three-phase would be even better.

On the plus side, the recharge cost only $1.26—not even pocket money. But factored into this is the cost of the battery replacement cycle and this remains an unknown; Pipistrel is still collecting data on it. Currently, the replacement cost is $22,200. Also, the engine currently has a 300-hour bearing/seal replacement requirement, for which it has to be sent back to Slovenia. At 20 minutes a pop, that’s about 900 flights so it’s not an imminent thing.

Silver said he didn’t see how this airplane could fit into U.S.-style training and I agree. If it ever gets certified—no guarantee there—its legs are too short for efficient training and I’m not sure I see its advantage as a pattern-cycle trainer. Cheap to operate, yes, but also tender. The POH is festooned with special warnings and conditions that even a CFI might have trouble mastering, much less a primary student. Then there’s the price. At $209,000 (€185,000) the Velis is more than twice the price of the Rotax-powered Alpha Trainer at $93,873 or €83,100.

Given that disparity in price, who buys the Velis? Perhaps a flight school driven by early adopter interest in electric flight or a private owner with similar predilections. Anyone with technical knowledge of the challenges involved in getting an airplane this far would have to be impressed with the Velis. But for now, it’s just a door opener to what comes next.

The Trouble With Flaperons

Like the Alpha Electro before it, the Velis has full span flaperons that provide both roll control and additional drag for landings. While this is an elegant solution, it has a downside related to landing speeds. With its low-drag, high-aspect-ratio wing, the Velis needs all the help it can get to slow down for landing. The published stall speed is 47 knots, the clean stall speed 54 knots. As LSAs go, that’s on the high side. The Flight Design CTLS, for example, is 8 knots slower, at 39 knots.

Flaperons complicate this because if maximum effort roll is needed at slow speed—say in turbulence when landing—the high side wing will suddenly have less flap than the low side and if the speed is between Vso and the clean stall speed, that wing can instantly stall. The only way to raise it is brisk application of opposite rudder to accelerate the wing out of the stall. Otherwise: potential prang.

Isaac Silver told me this happened to him while landing on a gusty day. Reflexive application of rudder saved it. A student would need to be forewarned and equipped to deal with this. In any case, Silver recommended not attempting a full-stall landing, but flying the airplane on similar to a wheel landing in a taildragger. That worked for me, but the Velis requires different technique than other LSAs.

This article originally appeared in the February 2022 issue of Aviation Consumer magazine.

For more great content like this, subscribe to Aviation Consumer!

Great article, Paul. Thanks for relating your experiences on a subject often discussed with high levels of conjecture on both sides of the issue.

Hi Paul,

Thanks for such an in depth article. I’ve been in electric vehicles and aircraft for over twenty years. To avoid confusion is daily discussion we adopted the convention that “motor” always meant the electric motor, and “engine” always meant the liquid fueled engine.

And, although energy and power are sometimes used interchangeably, energy is always a quantity and power is always a rate of energy use. Think of it as energy is in the fuel tank and power is under the hood. If interested, more can be learned at EnergySense.com.

Thanks again.

I used to think electric aircraft were going to be a great aviation evolution. What’s not to like? Pennies to charge and the reliability of an electric motor. Then I started doing the math as it were, which you inspired. As the Pipistrel Velis Electro POH states, there are many things that can go wrong with an electric aircraft: range anxiety, batteries are very heavy, batteries can overheat, battery fires are fatal, bearings can fail, electrical connections can corrode, power controllers can fail, etc. At 100 to 1 power density ratio, batteries have a long way to go before they can provide the same power output as an avgas fueled combustion engine.

People who purchase EVs usually fail to calculate that EV tires are twice as expensive as normal sedan tires. Why? EVs weigh twice as much for the same load carrying capacity. What is the enemy of any aircraft? Weight.

Another huge problem with going all electric is the capacity of the electrical grid. Coal and gas powered continuous power generation is being replaced by solar and wind. The problem is that solar is only 17% operational and wind is only 37% operational. Where is the additional electricity going to come from? No one has an answer, the least of which are the bureaucrats who are mandating these regulations.

Another big problem is the lithium and cobalt required for batteries. There is already a global shortage of lithium and processing lithium for just one vehicle requires tons of water. There is only one lithium mine in the US and the US only produces 1% the global lithium.

EV’s are not twice as heavy as ICE vehicles; do the math.

Lithium is a very common element in seawater; extraction and refining is ramping up exponentially. “Mining” for lithium is not that common, it is normally extracted from brine.

Cobalt is not used in at least half the available EV batteries in production, so a “shortage” of Cobalt is not an issue.

The numbers given for solar and wind availability are incorrect; wind farms are only built after a minimum two year study with a tall tower; they are never built unless there is a least 75 percent availability, which, if required maintenance is considered, is higher availability than nuclear.

In the early days of aviation or “horseless carriages” lots of pundits “proved” that they would never be successful; pundits, who like some of the commenters here, clearly did not understand potential.

If those pundits back then had their way we’d still be pulling carts with stone wheels and baying at the moon once a month.

I think electric motors are ideal to power the transportation sector. I doubt anyone can argue that the motors are currently hamstrung by Li-ion batteries. Do the math. Our Arrow can venture 500 miles in any direction with reserves on 500 lbs of gas. To match that, a battery powered aircraft would require batteries weighing far more than the aircraft itself. Am I wrong? Pulling carts with stone wheels may have served its purpose for a long time. Most advanced weapons still use gunpowder (albeit highly modified) developed in the 9th century. Gas still powers most of the transportation sector and still holds advantages over batteries. I know electric motors are too good to ignore but I think they’ll become primary mainstream movers only after a different energy source comes online.

““Mining” for lithium is not that common, it is normally extracted from brine.”

Can you point me to a source for that, because US DoC data shows that in 2022, the world’s largest lithium producer by far was Australia, and almost all of that is from strip mining. The Greenbushes mine alone is almost 25% of the lithium produced in the world 2022. You can see the hole in the ground from space. It’s an environmental nightmare.

In a distant second is Chile, and all of their production is from salt flats. These are in the desert and nowhere near the ocean. Messing with salt flats is not without its own environmental woes. In third place is Bolivia, using the same salt flats.

So it seems most lithium is not from any environmentally friendly process.

A Civic is 2935 lb gross and a Tesla Model S is 5185 lb, a 76% difference. Not double the weights, but similar sized (within 8 inches) so not completely apples and oranges

Again I am confident that e-aircraft will eventually be available. But if the tech were close (5yr?) from being ready, we’d see an experimental aircraft demonstrator with a range farther than I can bicycle. New battery tech will come, but there’s no guarantee of it, and the current Li+ density is only a quarter to a third of the energy density of what would be practically be needed for a certified, dispatchable, reliable, serviceable aircraft

Interesting article; this aircraft has to be seen as a very early example.

The biggest issue is battery energy density.

CATL recently announced batteries with approximately three times the energy density of those in the Pipistrel; that changes things completely.

Also, NIO announced that they will be shipping cars with solid state batteries this year; another giant step in weight and energy density.

The Pipistrel is like some early “Horseless Carriages” not that great, but interesting.

Progress will be very swift; the change is coming quicker than most people can understand.

You may want to re-read your sources. I believe CATL’s new batteries claim to manage 3 times the cell lifespan, not energy density. Energy density gains are more on the order of 15 percent; respectable but not revolutionary. As for NOI, depending on how one interprets the relatively vague information available, my quick math indicates they may have managed a 15 to 20 percent energy density improvement at the cell level. Both are improvements, sure, but they hold with the point the article makes. They also support the engineering reality that it is unrealistic to expect energy density to scale at the rate popular hopes and political ambitions would like to dictate.

This is the kind of story that makes AvWeb perhaps the best aviation-reporting “magazine” in the business. Where other aviation sources are often “cheerleaders” for new products, Paul Bertorelli can always be counted upon to provide a “here it is, warts and all” narrative–the good AND the bad. Paul isn’t negative–just a practical pilot–a pragmatist–a person guided more by practical considerations than ideals.

I also fly gliders, and Paul’s mention of the Taurus self-launching glider puts electric airplane flight in perspective. The Taurus is a perfect example of what electric airplanes CAN do–self-launch–climb to find lift–shut down–and instantly available in case you need to find more lift. That works for gliders–but not for trainers–or even for “fun-flying airplanes.

Thanks for putting electric flight into perspective–at least until a better battery is invented!

I am confident that e-aircraft will eventually be available.

However, if you are left cautiously optimistic about their current practicality from Paul’s article, I’d suggest spending 10 minutes asking the google about “POH-128-00-40-001” reading the POH and look at the TCDS for the “B” model (the electric powered version model Virus SW 128, not the Rotax main type SW 121), and compare its operating limitations to what you know about the primary flight training environment

For me it was a splash of cold water in the face to wake you up to reality, and it was very hard for me to see its practicality in the demanding conditions of its primary training use-case with all of its operating limitations, warnings, etc.

As much as a C152 with its bright-orange interior, faux wood panel, and Narco radios belongs in a museum, it still seems like it is not going anywhere until there are enormous improvements in battery power/mass ratios, charge cycle times, etc.

We purchased the Velis purely for R&D, not for use as a trainer, and for that purpose it has exceeded all expectations. As compared to the very limited Electro, the Velis has allowed us to complete a fairly rigorous series of test programs. We’ve operated the plane for more than 100 cycles now, we’ve seen hardware failure modes, encountered performance considerations that are unique to electric propulsion, had to deal with maintenance complications and training issues related to the language and lingo as well as system complexity. We’ve flown dozens of FAA test pilots and flight test engineers to give them their first exposure to the technology.

Mission ready for the US NAS, not really. But as far as a technology demonstrator and R&D platform, this little plane has launched the field forward. So for all the naysayers, so what if it has the utility of a pre war t-craft with a fuel leak, it does have a mission that’s important right now and the technology will advance.

Thanks Paul for bringing this back up. It’s timely as we are getting ready to release final reports (which will be public) and start additional, targeted test programs to assist with some new certification questions and to develop tools to make electric flight feasible.

What a breakthrough.

Horse-drawn carriage pundits declared in the 1800s that there was no need for fossil-fueled engines, because a diet for horses was being developed that would increase the power of horses tenfold. Now the descendants of these pundits say with the same certainty, that the energy density of batteries can be multiplied in the near future. I hope they are right this time.