Having survived a crash, it’s easy to recommend shoulder harness upgrades in aircraft that still sport old-school lap belts. Without a shoulder belt, I’m convinced my flailing noggin would have smacked a panel full of new Garmin avionics—and it wouldn’t have been pretty. But taking that safety net one step further are airbag seatbelts, which have become the standard in many new airplanes and widely retrofittable in older ones. I think it’s money and shop time well spent.

Arizona-based AmSafe has been at the top of the airbag seatbelt market and has the OEM market cornered, and the company has a growing list of aircraft for which its seatbelt airbags can be installed as retrofit equipment. In general, if you own an all-metal or composite aircraft built after 1960, there’s a good chance that you can have seatbelt airbags installed for at least the front seats, and possibly for the rear seats, too.

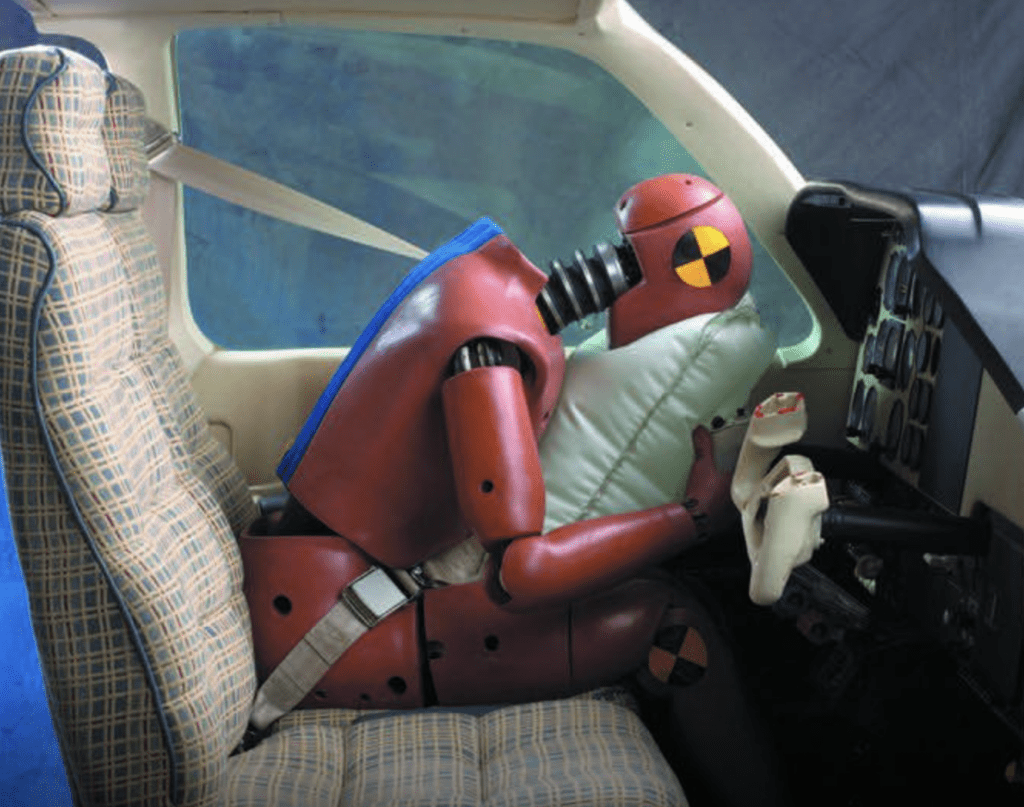

We’ve come a long way. But initially, executing the airbag interface in small GA planes wasn’t without challenges, especially from a hardware standpoint. Ultimately, AmSafe came up with a system in which the airbag was stored in the seatbelt and/or shoulder harness. Then, through the time-consuming and pricey FAA approval process, AmSafe custom-designed the systems for individual types of aircraft and each airbag was tailored for the flail space in front of the occupant of the particular type of airplane. That’s no easy task because that meant designing the system to work on every body—from the smallest 5th percentile adult female through the largest 95th percentile adult male.

But it isn’t only about getting the hardware right. AmSafe also had to demonstrate that an airbag’s inadvertent deployment would not adversely affect control of the aircraft and would not knock the pilot’s hand off of the yoke or stick. Moreover, what if the airbag inadvertently deployed? Would that in itself cause a crash? Working with the Anchorage, Alaska, FAA office (which had a sharp focus on reducing the GA accident fatality rate), AmSafe ultimately developed (and the FAA approved) an airbag system that could be installed on virtually any seat in any general aviation airplane type certificated prior to the regulations requiring 26-G seats. What’s even better is that the AmSafe airbag system could be used on seats where a shoulder harness could not be installed. For lots of vintage aircraft, that’s huge utility.

AmSafe’s latest system is called SOARS (State-of-the-Art Restraint System) and is offered for under $3000 for two seats. That’s a sizable price reduction from earlier systems. The system deploys when the crash sensor detects a longitudinal force at or above 6 Gs for approximately 50 milliseconds. The seatbelt airbag deploys upward, not into the face of the occupant. Each kit includes a foam body block sized for a 50th percentile adult to allow the airbag to be adjusted to the correct position on the seatbelt. The crash sensor and systems electronics are contained with an Electronic Module Assembly (EMA) that is powered by a non-rechargeable lithium battery.

As for the upkeep, the SOAR’s battery and inflator must be replaced after 10 years. Otherwise, inspection is only required during the annual, no special tools are needed, and the EMA has a push-to-test switch that reads out the health of the system. The electronics are independent from the aircraft’s electrical system. The installations I’ve been involved with (Beechcraft and Cessna models) have generally taken around six hours or less to complete. SOARS is approved for installation on well over 400 types of aircraft, plus it can be used to replace two-, three-, four- and five-point restraints. Return-to-service is accomplished by an FAA Form 337, signed off by an A&P mechanic or repair station.

For additional information, visit www.amsafe.com and see sister publication Aviation Consumer for more on seatbelt and airbag retrofits.

I’ve reached out to them periodically over the years regarding applications for my RV-7 and experimental aircraft. Have not received a response, which is indicative of a poor customer service attitude likely based on “having the market cornered”. The industry needs more competition in this and other safety-related areas.

Many manufacturers of equipment approved for use in certified aircraft literally will not talk to the experimental community. Having been on the south end of two lawsuits, I don’t blame them.

I noticed the crash dummy was in a 3 point harness. I recall reading that, while certainly offering more crash protection than a lapbelt alone, 4 and 5 point inertial reel harnesses approach air bags in improvement of crash survivability. The airbag enhancement adds even more margin… for crashes that are straight in. Airbags don’t offer much margin for side loads likely to be encountered in many situations. So far my read of the crash protection literature says 4 or 5 point inertial reel + a helmet are the winning combination of stacked protection for a multidimensional rapid deceleration event common in many accidents.

Cessna has been installing AmSafe inflatable restraints for a long time now.

I’m amazed at how many people don’t want to spend the money to maintain them so they rip them out when the inflators time out.

They aren’t Chapter 4 items. As a part 91 operator I think I’d rather have an out of date system than none at all…