A series of transitions defines every pilot’s life. For Bill Anton of Satanta, Kansas, retiring after 35 years as an ag banker coincided with maturing flying desires, “from cross-country and aerobatics to fun flying out in the boondocks.” Now 72, “I’m thinking of how many more years of good flying I might have left,” he said. After more than 800 hours in the Van’s Aircraft RV-8 he finished building in 2006, “I was ready for something different.”

A Bearhawk is certainly different. He chose it by following the same path that led him to the RV-8 in 1998, when he decided it was time to build his own airplane after flying a Piper Arrow for 17 years. “I sat down and wrote a set of criteria for what I wanted. I live out in the country, have a grass strip and hangar, so I needed something that would handle grass. And I wanted something that would go cross-country” with at least one passenger, his wife, Nancy.

His list compiled, Anton sat down with the directory of available amateur-built designs “and started crossing out those that didn’t meet my criteria,” he said. That included a requirement for how many were airborne. “A lot of them had only four of five flying, and those I kind of eliminated.” Looking at his final candidates, “Since I’m a fighter pilot wannabe, I picked the RV-8,” he said.

The Antons haven’t moved from their Anton Flying UV Airport (SN98), so those criteria remain. Measuring 2150×100 feet, Runway 1/19 forms one side of their 15-acre property. Steps from the hangar is the house they built between 1979 and 1982 on the remains of the family’s southwest Kansas homestead. The Flying UV, so called because one arm of the U flies over the V, is the family brand, the initials of the homestead’s founder, Ulysses Victor Anton.

The RV-8’s usual passenger is also 72, “and it is getting to be a struggle to get in and out of the back seat.” Anton said. “I’m not so sure the Bearhawk is any easier with those 31-inch tires, but once you’re in, it is more comfortable.”

Comfort, cross-country cruising and cargo capacity rounded out Anton’s criteria for a backcountry airplane that can go cross-country. “Some of them are 100-mile-per-hour airplanes,” he said, adding that he was a Cessna 172 partner for about two months. Relating a midsummer cross-country with his wife, “It beat us up and took a long time to get there, and I didn’t want to do that.” The Bearhawk cruises at 150 mph, “so you can go someplace in it.”

Speaking from 12 years of RV experience, “You have to be real careful what you pack,” Anton said, adding that when they camped at Oshkosh, it was Spartan. “With the Bearhawk’s big ole back doors, you just throw stuff in and take off.” Taking a friend to EAA AirVenture 2019, he said all their camping gear, two tents, sleeping bags, mattresses, and a huge Yeti cooler “hardly filled up the back.”

To use the space more efficiently when carrying two passengers, Anton built a single back seat that replaces the side-by-side bench. It made its first flight in October 2019, when Anton and his sons, Marc and Erik, both pilots, flew to Critter’s Lodge, a private aviation preserve in East Texas, for its annual long weekend fly-in. “They had probably 20 or 30 airplanes there” at the grass strip just off Highway 7 between Crocket and Centerville, Texas.

Building Decisions

Anton had plenty of steel tubing to build the frame for that single back seat. “Because I was retired, I’d have a lot of time, and with the hangar right here I decided that I was going to scratch build the whole thing.” Explaining that the Bearhawk is built like a Maule, a fabric-covered steel-tube fuselage with all-metal wings, Anton said he bought the raw materials days after he retired in January 2009.

Following the homebuilder’s mantra to do something every day, Anton started building parts. “If you get hung up on building an airplane, you’ll never get there.” Each part presented its own challenges and decisions. He started making wing parts after deciding how to cut out the ribs and their lightening holes, how to bend them and how to smooth them out.

Working from full-scale plans, he cut out the rib form from a piece of 3/4-inch oak. A router turned sheets of aluminum into rib blanks, and a Scotch-Brite wheel deburred them. Then, one at a time, he clamped the blanks to the form block and beat them into shape with a big rubber mallet. Finally, he straightened every rib with his flanging tool.

“It took about seven years to build the wings. Thinking that this is going to take me forever, that I’m going to be too old to fly it if I have to put that fuselage together, I bought one from Bearhawk Aircraft.” Given its complexity and the building skills it requires, he doesn’t recommend the plans-built Bearhawk to first-time builders. With the factory-built fuselage, no welding is required. However, Anton chose to weld a multitude of mounting brackets and tabs for his control cables.

While building, Anton regularly flew his RV-8. On their way to Tucson, where their son Erik was retiring after 20 years as an F-16 pilot, “Just past Lordsburg, New Mexico, the oil temp started going up and the oil pressure started going down.” Heading to their closest refuge, Wilcox, Arizona, “The engine cratered with a big bang,” he said calmly. “I set it down on a dirt road a farmer had just graded out in a big orchard 2 miles south of Interstate 10. I didn’t bend anything.”

The failed RV engine was a rebuilt powerplant, as was the Bearhawk’s zero-timed 260-hp Lycoming IO-540. “It was a really good deal—I got it for $20,000,” but he reconsidered it after the off-airport adventure. “A friend had taken his engine to America’s Aircraft Engines in Collinsville, Oklahoma, so I hauled my engine down there. They put it on a test stand, it ran perfectly, and that gave me the confidence to put it on the Bearhawk.”

A three-blade MT prop turns the Lycoming’s horsepower into thrust. “I don’t know if it is any better than a two-blade prop, but it looks cool,” he said. And it has better ground clearance than a two-blade, always important when looking at backcountry operations.

Bush wheels also increase the prop clearance. He started with 26-inch Goodyear tires. “Practically speaking, they are really a better compromise for landing on pavement and dirt. They are a tougher tire and will last longer, but I really like the look of those 31-inch Alaskan Bushwheels.” A 10-inch tundra tire is the third point of contact. An early Bearhawk builder, Eric Newton, who wrote the builder’s manual and is really involved with the online builder’s group, developed it for the backcountry flyers.

Big backcountry tires are not the Bearhawk’s only distinguishing feature. It has two pitot probes. A military-issue heated pilot/static head, like those on a P-51 Mustang, extends from the left wing. An eBay find, “I really like the military combination of the pitot tube and static port” in a single unit.

But the military unit would not work with the Dynon system, which requires a pitot tube plumbed to provide the source data for angle of attack. That pitot tube extends from the right wing. Instead of putting in a static port, Anton installed the military unit and used its static port. “It’s a nice conversation starter,” he said, if people notice the bilateral probes.

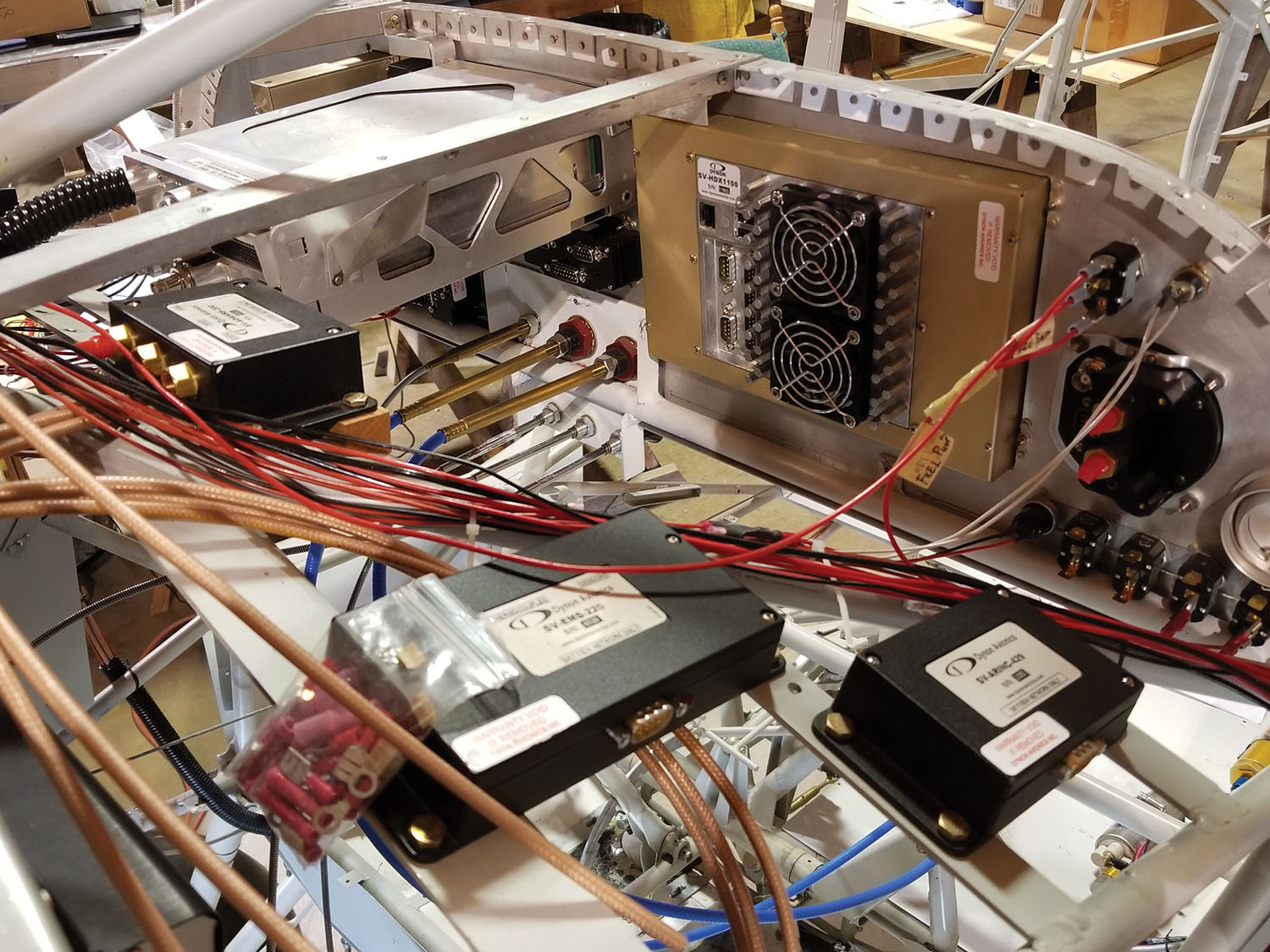

“Being an old Air Force avionics and instrument guy who worked on F-4s, I like that stuff and went all-in on the panel.” Anton installed a Dynon HDX system that includes a touchscreen display, autopilot, communication radio, intercom, transponder, and ADS-B Out and In. For redundancy, he installed a Garmin GNS-430 GPS navigator and G5 display set up for IFR.

Growing up in Satanta, the self-described farm boy earned an ag degree at Kansas State University. “That was the middle of Vietnam, so I was [military draft category] 1A the minute I graduated.” Instead of waiting for the notice of Vietnam ground pounding, he enlisted. “I’ve liked airplanes all my life; when I was 5 I’d run out the door anytime I heard an airplane to see what was flying over…it was a miracle.”

The Air Force experience planted Anton’s safety consciousness and the important contribution made by a second set of experienced eyes. For his avionics work, Anton turned to an avionics technician in Liberal, Kansas, 30 miles south of Satanta.

Having never worked with fabric, Anton sought an expert to help him cover the Bearhawk with Oratex. The company’s “main guy lives in Anchorage,” Anton said, and talking to him at Oshkosh, he recommended another Anchorage resident, “so I paid his way to Dodge City.” They covered the airplane in 10 days, with Anton doing all of the rib stitching and taping by himself. “It goes on real easy and shrinks down real tight.”

Anton painted the metal wings to match the fabric, but there’s no painting involved with Oratex, so he turned to decorations. “If you look at Bearhawks, a lot of them use a bear claw. I liked the hawk idea,” and he found his on the internet. “It’s a tattoo stencil.” The airplane’s name, Freedom II, has several meanings. “My RV was Freedom and this is my second homebuilt, then there’s the freedom of flight, and then reality that freedom is not free.”

As he did with his RV-8, Anton turned to Crotts Aircraft Service in Dodge City, Kansas, roughly 60 miles east northeast of Satanta. One of the full-service FBO’s maintenance offerings is Experimental aircraft builder’s assistance, said Anton, adding that one of its maintenance technicians had built several RVs. “I was still working, so I took off every Friday for four months and went up there” for a long weekend of work.

He did the same for the Bearhawk, with two major differences. “Being retired, I either flew the RV or drove there every day,” Anton said. He finished the RV in four months of long weekends. “The Bearhawk was six months of working with the Crotts’s crew every day.” It is a stock airplane, except for the extra windows in the doors. “I thought they looked good, and it is really amazing when you’re flying! You can look straight down from the left door.” He also installed a skylight and modified the top of the fuselage to remove the “Bearhawk hump.”

First Flight

Prepared by more than 800 hours in his taildragging RV-8 (N46BV for the year of his birth and his name, Billy Victor) and another hundred hours or so in the Aeronca Champ he once owned, Anton made the maiden flight of Bearhawk N47NL (for his wife, Nancy Lynn) on November 2, 2018. “I kissed the ground, got in that baby and away we went. It was a little out of trim. The Bearhawk is a very rudder intensive airplane compared to the RV-8. When I took off, I was puckered up because I was trying to keep it upright. It wasn’t like it was rolling over on me, but it had a heavy wing and the rudder was out of trim.”

Adding trim tabs on all of the control surfaces resolved the problem during his Phase I test period. Studding the wing with vortex generators improved its low speed performance. Still, he said, “You really have to fly it. No sleepy feet.”

Anton started flying as a high school senior and soloed at K State. “Then life got in the way. College, the Air Force, I got married in 1969 and out of the Air Force in 1973. I finally got my license in 1975,” an instrument rating in 1996, and a commercial pilot certificate in 1998.

“In the early ’90s I got a glider rating. Maybe that’s my next project, now that I’m a retired builder. Maybe I’ll go find me an affordable glider. I’ve got a buddy about 30 miles from here who’s a spray pilot; he also owns a couple of gliders and does the tow thing.”

Southwest Kansas has changed a lot, he said. “Growing up here in the 1950s and ’60s, we were mainly dry land wheat farmers. It has evolved into irrigated corn and alfalfa and soybeans.” They are the green in the center-pivot crop circles, each a half mile in diameter that cover the landscape in a tight polka-dotted pattern.

What has not changed is that “a lot of ole farm boys here in southwest Kansas build airplanes, which is kind of an amazing thing,” Anton said. “There are a lot of grass runways in a 50-mile radius, so I’ve hit every one of them three or four times. I’ve been to a lot of their fly-ins, so I know them pretty well.”

But this shouldn’t be surprising. Given the distances between them, airplanes are a good way to get around. Consider this: In the 1910s, the founders named Satanta for a Kiowa chief. It covers 0.59 square miles and, by the 2010 census, is home to 1139 people. Situated a mile north of town, the Satanta Municipal Airport (1K9), activated in December 1944, is home to 14 single-engine aircraft.

That works out to 81 people per airplane, not counting the airplanes that don’t live at the airport. Although the Bearhawk lives at home, Anton manages the city-owned airport, a self-service source of 100LL. “The manager is not a paying job, and the flight instructor who probably taught half the guys in southwest Kansas to fly got old enough and gave it up. I decided we needed somebody to make sure things were okay, so I took it on around 1995.”

With the Bearhawk flying, Anton sold his RV-8 to a friend’s son-in-law after AirVenture 2019. A former Marine fighter pilot going to work for United Airlines, “I’m feeling real comfortable selling to him; I know that he’s not going to take it out and do something stupid.”

With more room in his hangar, he started on some Bearhawk modifications. “I wasn’t happy with my cylinder head temps, and at Oshkosh [Bearhawk Aircraft’s] Mark Goldberg gave me some numbers [Bearhawk designer] Bob Barrows talked about” that compared the areas of the cowl inlets and outlets. Anton enlarged the outlet on the bottom of the cowl and reworked its flange. “I’m not totally happy with it. I think maybe my baffling isn’t real tight in one place, so I’m still working on it” and doing a number of test flights.

Anton flies a lot. In the 10 months since the Bearhawk’s first flight, “I’ve got 136 hours on it,” he said. “I’ve never done that. When I worked, I was lucky to get 30 or 40 hours a year.” Needless to say, retirement “has been fun!”

Bearhawk 4-Place

- Typical completed price: $90,000–$120,000

- Typical build time (quickbuild kit): 1000–1200 hours

- Bearhawk N47NL (mostly plans-built): 3000–4000 hours

- Number flying (at press time): 100+

- Powerplant: Lycoming IO-540, 260 hp

- Propeller: MT 3-blade, constant-speed

AIRFRAME

- Wingspan: 33 ft

- Wing loading: 15 lb/sf

- Fuel capacity: 50 gal

- Maximum gross weight: 2700 lb

- Empty weight: 1604 lb

- Typical useful load: 1096 lb

- Full-fuel payload: 796 lb

- Seating capacity: 4

- Cabin width: 42 in

- Baggage capacity: 200 lb

PERFORMANCE

- Cruise speed (31-inch Alaskan Bushwheels): 140 mph

- Maximum rate of climb: 1500 fpm

- Stall speed (landing configuration): 43 mph

- Stall speed (clean): 46 mph

- Takeoff distance: 200–400 ft

- Landing distance: 400 ft

Specifications provided by Bill Anton and Bearhawk Aircraft.

This article originally appeared in the July 2020 issue of Kitplanes magazine.

For more great content like this, subscribe to Kitplanes!

Thanks for reprinting this article. I did not realize Oratex allowed that much light to pass through. I would paint a wood airframe’s under-fabric structure with silver paint to block UV, as was done on some older wood gliders.