Van’s Resumes Shipping Kits, 65 Percent Of Customers Renew Orders

Van’s Aircraft says 65% of customers have agreed to pay more for their kits and more than 100 of those kits have now been shipped. The company, which went into…

Van's Aircraft says 65% of customers have agreed to pay more for their kits and more than 100 of those kits have now been shipped. The company, which went into bankruptcy a month ago, says it's ramping up kit deliveries but is still buried under email inquiries. "Our shipping throughput will increase over the coming weeks, and we will post progress updates," the company said in an update posted Saturday.

Van's also said it's tackling the parts order backlog that resulted from supply chain issues over the last couple of years. "Our supply chain has been improving and we have team members working with our suppliers to continue to drive improvement in this area," the update reads. The company says it's also started directly contacting 1,800 customers who have major structural parts that have laser-punched rivet holes that will be replaced by the company. "All affected customers will be sent an email containing an individualized list of affected parts for each kit they have received," the update said.

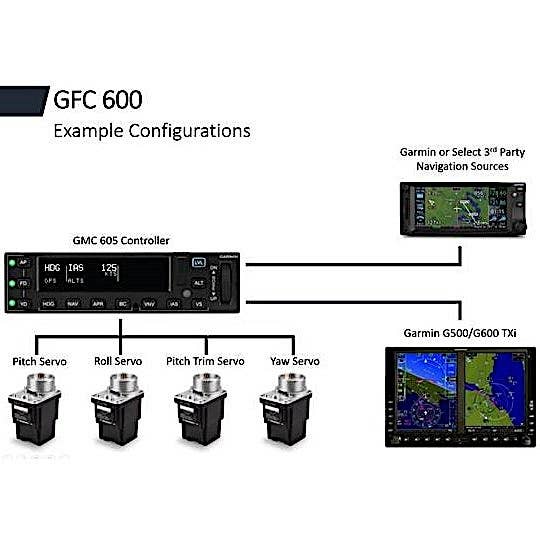

The company says it's also working with third-party suppliers regarding orders for kits that included engines, avionics and propellers and had hoped to have some news regarding those orders this week but bad weather in Oregon forced closure of the plant for three days. "The planning that is currently underway includes a look at scheduling, lead times, payments, pricing, customer deposits, and more," the update said. "We are working to have our plans shared by the end of next week with those customers who have open orders for engines, propellers and avionics kits."