FAA Reopens Cherokee Spar AD To Comments

The FAA has opened up the Piper Cherokee spar corrosion AD for comments again after AOPA pressed for less expensive ways to address the potential problem. The AD, which was…

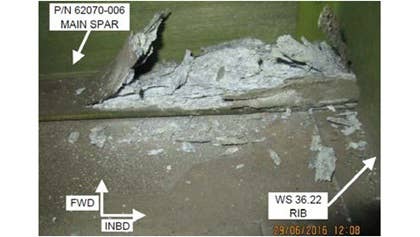

The FAA has opened up the Piper Cherokee spar corrosion AD for comments again after AOPA pressed for less expensive ways to address the potential problem. The AD, which was initially proposed in November of 2017, will continue to affect more than 11,000 Cherokees and Cherokee Sixes but some alternative methods of compliance suggested by AOPA have been included and the comment period reopened until Sept. 18. The revised AD also includes information from Piper “to add a minimum thickness dimension for the top inboard wing skin and to include procedures for reapplying corrosion preventive compound if removed during the inspection.”

The original AD called for cutting new inspection ports in the wings because the area of the potential corrosion is not easily accessible from existing ports. Among the AMOCs suggested by AOPA is the use of borescopes to look inside the wing through existing holes.