NTSB To FAA: Do Something About Oil Filter Adapters for Continentals

Citing a recent fatal accident of a Cessna 182 in California, the National Transportation Safety Board (NTSB) has renewed efforts to get the FAA to issue an Airworthiness Directive for…

Image: NTSB

Citing a recent fatal accident of a Cessna 182 in California, the National Transportation Safety Board (NTSB) has renewed efforts to get the FAA to issue an Airworthiness Directive for certain oil-filter adapters for Continental engines. The adapters are made by Stratus Tool Technologies (part of the Tempest Aero Group) but are often referred to by their original designer and manufacturer, F&M Enterprises. Some 11 accidents over the last 15 years have been linked to this filter adapter vibrating loose and allowing a loss of engine oil. Stratus has published a Mandatory Service Bulletin addressing the issue, but FAR Part 91 operators are not required to comply with this guidance.

The NTSB says the safety recommendation “is derived from both preliminary findings of ongoing investigations and our review of investigations and reports of airplane accidents in which the airplane was equipped with an oil filter adapter assembly installed under a supplemental type certificate (STC). In each of these accidents, oil leaked from the assembly, resulting in oil starvation to the engine and a subsequent total loss of engine power.”

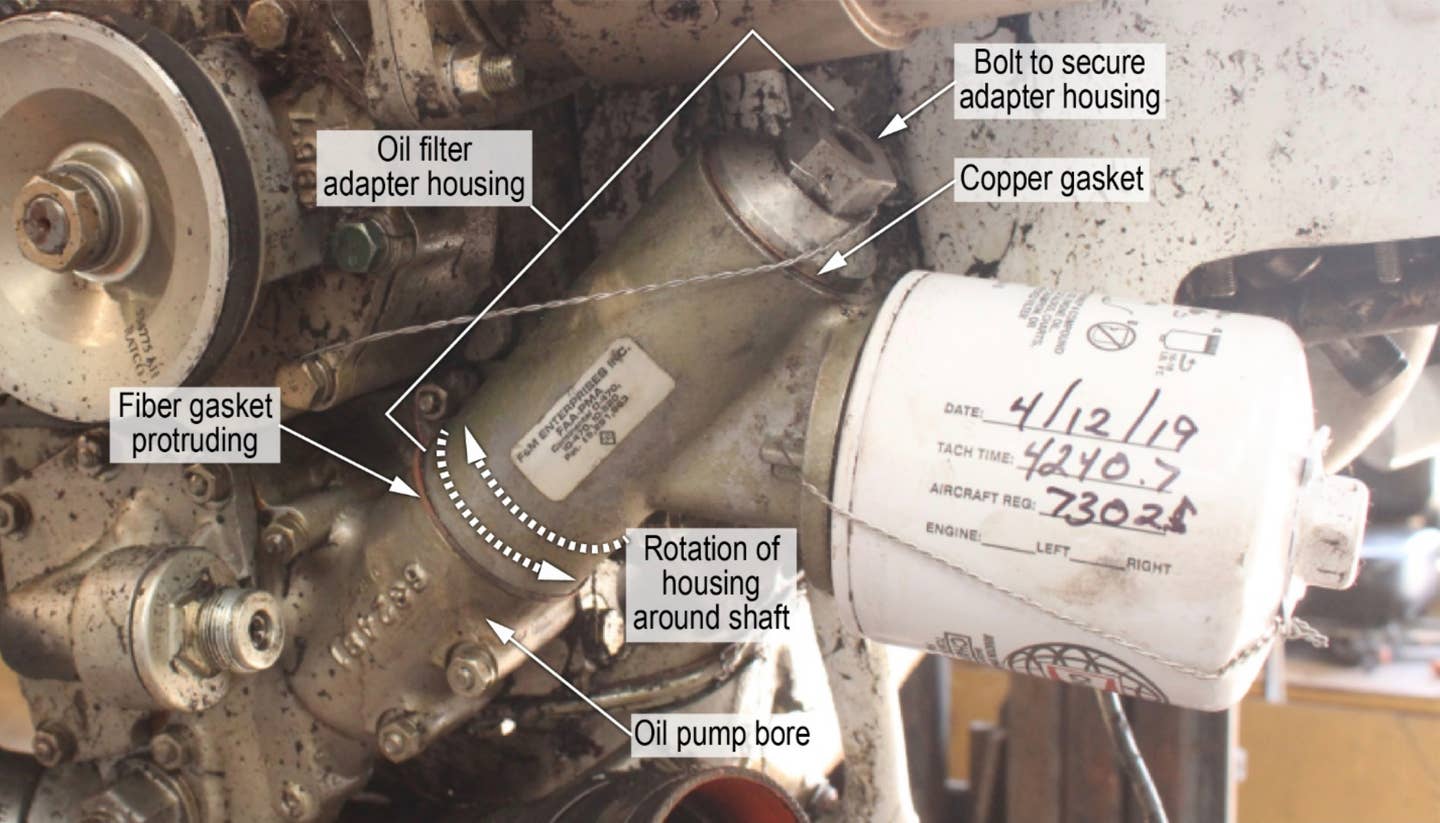

The Stratus adapters are designed to fit a wide range of Continental engines, from the small six-cylinder models (C-145 and O-300), certain of the larger IO and TSIO-360 engines, and a wide swath of the big-bore O-470, IO-520, TSIO-520, and IO-550 engines. These relatively early Continental engines were designed with a simple brass screen instead of a paper-element canister oil filter, and the adapter allows installation of a full-flow filter. The adapters screw into the space originally occupied by the brass screen. “Two gaskets were used in the oil filter adapter assembly kit: a fiber gasket located between the oil pump bore and the oil filter adapter and a copper crush gasket located between the oil filter adapter and the bolt used to secure the adapter housing to the oil pump bore,” according to the NTSB. “The fiber gasket’s purpose was to create a seal between the oil pump and oil filter adapter, and the copper gasket’s purpose was to create a seal at the top of the oil filter adapter housing.”

At issue is the likelihood that the filter adapter loosened and dumped the engine’s oil overboard. The NTSB notes that the manufacturers have changed maintenance guidance over time. “In May 2011, F&M [the original STC holder] modified the installation instructions to specify that the oil filter adapter must be installed using new gaskets,” says the NTSB. “In October 2013, F&M added a new section on gaskets to its ICA that directed the installation of new gaskets anytime the oil filter adapter is removed and re-installed, and the replacement of gaskets at 300 hours or 3 years whichever occurs first. More recent installation instructions have removed that requirement and instead specify, ‘There are no mandatory replacement times for any components.’”

The NTSB wants the FAA to act. “Although a SAFO [Safety Alert for Operators] that directs operators to inspect, correctly install, and maintain oil filter adapters would provide this important information to operators of airplanes with these oil filter adapters, compliance with a SAFO is not required. The NTSB therefore determines that because owners who operate airplanes under Part 91 are not required to comply with an SB or SAFO, Stratus’ SB-001 and the FAA’s proposed SAFO may be insufficient to address all affected airplanes, which could result in a gasket rupture, oil starvation, and a subsequent engine failure.”