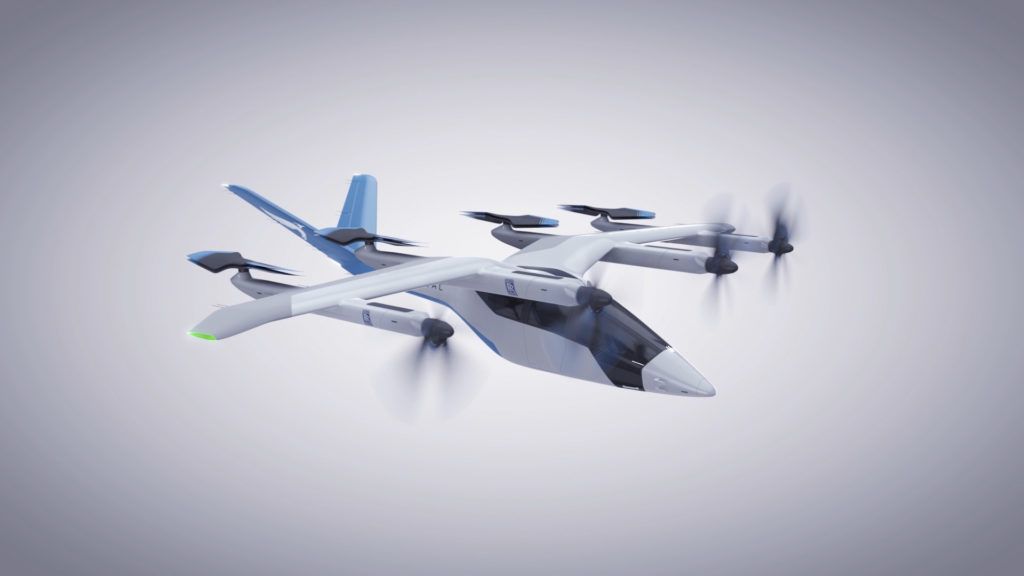

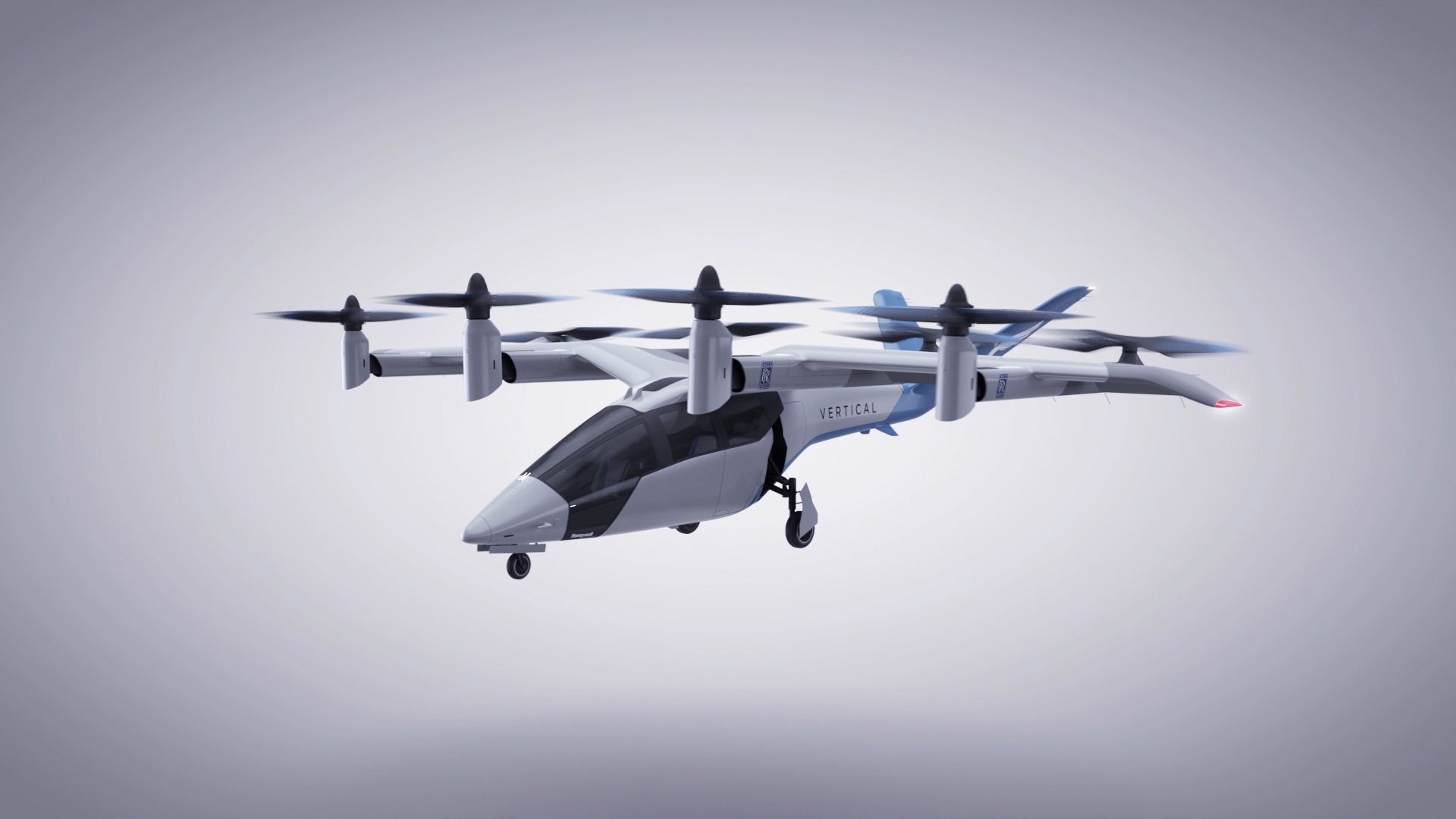

Vertical Aerospace’s four-passenger, all-electric eVTOL design will be powered by Rolls-Royce electric motors. The design, which uses a total of eight motors, is said to be capable of 200-MPH cruise, 120-mile range and vertical takeoff and landing. Four of the eight motors are housed in pivoting pods that allow them to provide vertical as well as longitudinal thrust, while the remaining four motors are for vertical lift only. It is “on course to certify in 2024.” Rolls is contributing around 150 engineers to the program; they will be based in Hungary, Germany, the U.K. and the U.S.

According to Rolls-Royce, “Vertical Aerospace is a key collaboration for Rolls-Royce Electrical as it marks our first commercial deal in the UAM market and builds on previous agreements to work with partners on demonstrator programmes. Rolls-Royce will design the system architecture of the whole electrical propulsion system, the electric power system that includes our latest 100kW-class lift and push electrical propulsion units, the power distribution and the monitoring system that will support operations.”

“We are delighted to collaborate with Vertical Aerospace for the electrical technology that will power their pioneering eVTOL aircraft,” says Rob Watson, director of Rolls-Royce Electrical. “This exciting opportunity demonstrates our ambitions to be a leading supplier of sustainable complete power systems for the new Urban Air Mobility market which has the potential to transform the way that people and freight move from city to city.”

Michael Cervenka, CEO of Vertical Aerospace, says “Rolls-Royce [brings] a hugely experienced team with deep expertise and cutting-edge electrical technologies to power our pioneering eVTOL aircraft.”

So what is new? Where are the super batteries? When you compare the investment cost, safety, down time for charging, how much weight you can carry, 60 miles out and 60 miles back, speed and the final tab to the passenger to existing travel methods or even an electric helicopter, what is superior?

C’mon Don. Give em a break. They’re on the leading edge of this thing. I’m sure the Wright Brothers had their critics too but look at us now. Jet setting around the globe without giving it a second thought. Energy storage is an issue and they know that. But, the fact that they can fly an aircraft over 100 miles on battery power is confirmation that the technology is worth pursuing. Being on the leading edge of anything is hard work. Thank god there are folks willing to put the time in.

…now, about those noisy propellers….

The outlook for sales is far better, and they are all so impressed with themselves and each other, lol.

Actually, there’s likely some truth to the first part. The ranges are expected to increase, and charging times decrease. Being skeptical is good, but there’s a lot of bright folks thinking it will happen.

Pilots keep falling as a percentage of population, but the examinations of why that is happening are mostly lazy. That’s natural because the ones who left or never entered the group aren’t around to be examined. I often rant here about the reasons, but one of them is that our aircraft are no longer practical.

Too many people live and work too far from a practical GA field. Helicopters are even more expensive to operate than light planes, but they can land in the city. So make an efficient VTOL and that changes the math. Add reduced noise, green halo effect, newness, and computer controlled. The result is something much more sellable than our dinosaur piston planes.

Assuming you can do it.

What do the 150 engineers say about flying in the winter time when batteries can fail, or when the customer must buy a new pack because the cycle life is too low? The higher the density – the lower the cycle life!

Just an observation, but if they wanted to shed a little excess airframe weight, they could go with fixed landing gear instead of the complex retraction system for the mains. It may not look as sexy in flight, but with good wheel fairings, the speed penalty should not be that great, and maintenance would be much simpler. (The aerodynamic drag on those feathered vertical propellers would pose much greater drag issues). Gear retraction mechanisms usually weigh around 40-50 pounds, which could certainly be better utilized with extra batteries.

As with all of these new VTOL designs, I always question how noisy 8 high spinning props would be compared to a helicopter. Is it really quieter? I’m not a fan of the noise my drone make and can’t imagine what it would bet like scaled up to full size.

Why is it that every one of these projects says they’ll have it certified in 2 or 3 years? Does the FAA even have the rules worked out?

Part of that may be wishful thinking, but I suspect it is mostly PR hype from the sales department. If they told you that certification is (more realistically) 7-10 years away, everyone would lose interest and forget about it.

Is it PR, marketing, investor relations or sales doing the hyping here? As a sales guy, I can assure you that any decent salesman will not likely lie to you. Companies that want to cheat you will hire a crooked sales manager who will then hire naive and inexperienced sales clerks to pound the phones and man the booth. It’s good sport tying them in knots over the phone and then telling them they will likely never see a commission because they work for a cheat.

In this case, I’m betting it’s PR because I’m betting they have not decided to ever market this aircraft. It’s likely a stepping stone or test bed design they suspect will never see market.