When looking at homebuilding magazines from the ’60s and ’70s, one factor that stands out is the engine selection: Most were using the small Continental engines, from the A65 to the O-200.

The main reason was availability. These engines were used by the thousands in the American lightplane industry after WW-II. As planes like Piper Cubs, Aeronca Champs and Luscombes were scrapped, their engines ended up available in the used market. Enter the “rag overhaul”: Buy an engine from the junkyard, wipe up the dirt and see if it will run.

The price was certainly right. In the plans for the Bowers Fly Baby, Pete Bowers wrote, “While the A65 is out of production, it is still plentiful on the secondhand market. Some with high time on them (500 hours or more since overhaul) can be had for $150–$300.”

I wish.

There are still a lot of the small Continental engines on the U.S. registry. Ten percent of the aircraft on the rolls mount the A65, A/C75, A80, C85, C90 or O-200 engine.

Still, only the latter is still being built. Everything else left the factory floors at least 50 years ago.

On paper, at least, the Rotax 912 looks like the perfect replacement. It’s light, it’s four-stroke and it even looks a lot like a traditional aircraft engine.

Before we pass the small-engine baton to the Rotax, there’s a fundamental question: Is it as reliable as the old traditional Continentals?

Fleet Size

How many of a given type of engine are installed on homebuilt aircraft?

It’s difficult to say. The FAA registry has spotty detail. The registry usually includes the specific engine type for aircraft mounting certified engines, but anything else is pretty random.

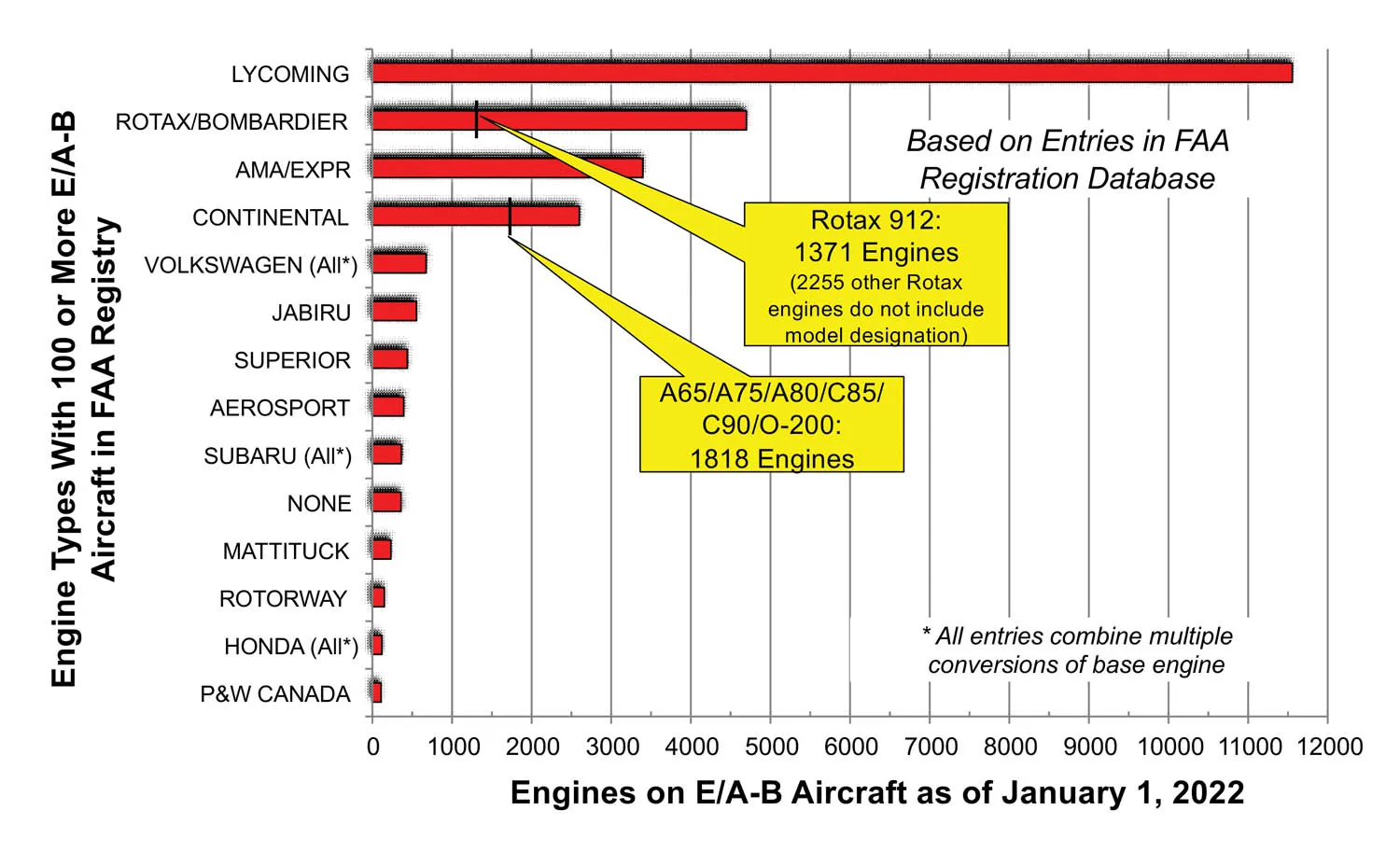

Figure 1 shows the number of engines installed in E/A-B aircraft. Of no surprise is that Lycoming leads the list. That’s about 40% of all homebuilt aircraft—not really surprising with Lycomings gracing the noses of thousands of RVs.

The surprise is No. 2: Rotax. Between “Rotax” and “Bombardier” listings, Rotax engines power about 17% of the homebuilt fleet.

Our problem is that out of the 4700 Rotax-powered E/A-Bs in the registry, almost half (2250) don’t specify an engine model. Some of those are undoubtedly Rotax 912s, but there are a lot of Rotax engine models. There’s no way to tell. About 1300 E/A-B registrations do specify models of the Rotax 912—but certainly additional examples lurk in the model-not-listed category.

Of the cases where a Rotax-powered aircraft does have its engine model included, over half are Rotax 912s. So there are likely to be another thousand 912s in the homebuilt fleet.

Number three on the list throws our statistics for a tizzy: One of every eight homebuilts has the engine listed as “AMA/EXPR.” For whatever reason, the builder decided not to list the engine make or model. These could be just about any engine type, including Rotax 912s, Continental O-200s, or any number of auto conversions.

Continental comes in at No. 4, with almost 2600 installations on E/A-B aircraft. About 1800 of them are the “small” Continentals, A65s through O-200s.

Picking The Accidents

Normally, when I compare homebuilt aircraft types, the basic factor is the number of accidents that were triggered by a loss of engine power for any reason. These account for nearly a third of all homebuilt accidents.

However, when comparing engines, this is rather unfair. It includes cases where problems occurred with the aircraft fuel system or even the instances where the pilots ran out of gas.

Instead, let’s look at the instances where the loss of power was due to a mechanical failure of the engine. This includes both cases where the engine spontaneously quit, as well as the incidents where the builder’s or maintainer’s errors led to the failure.

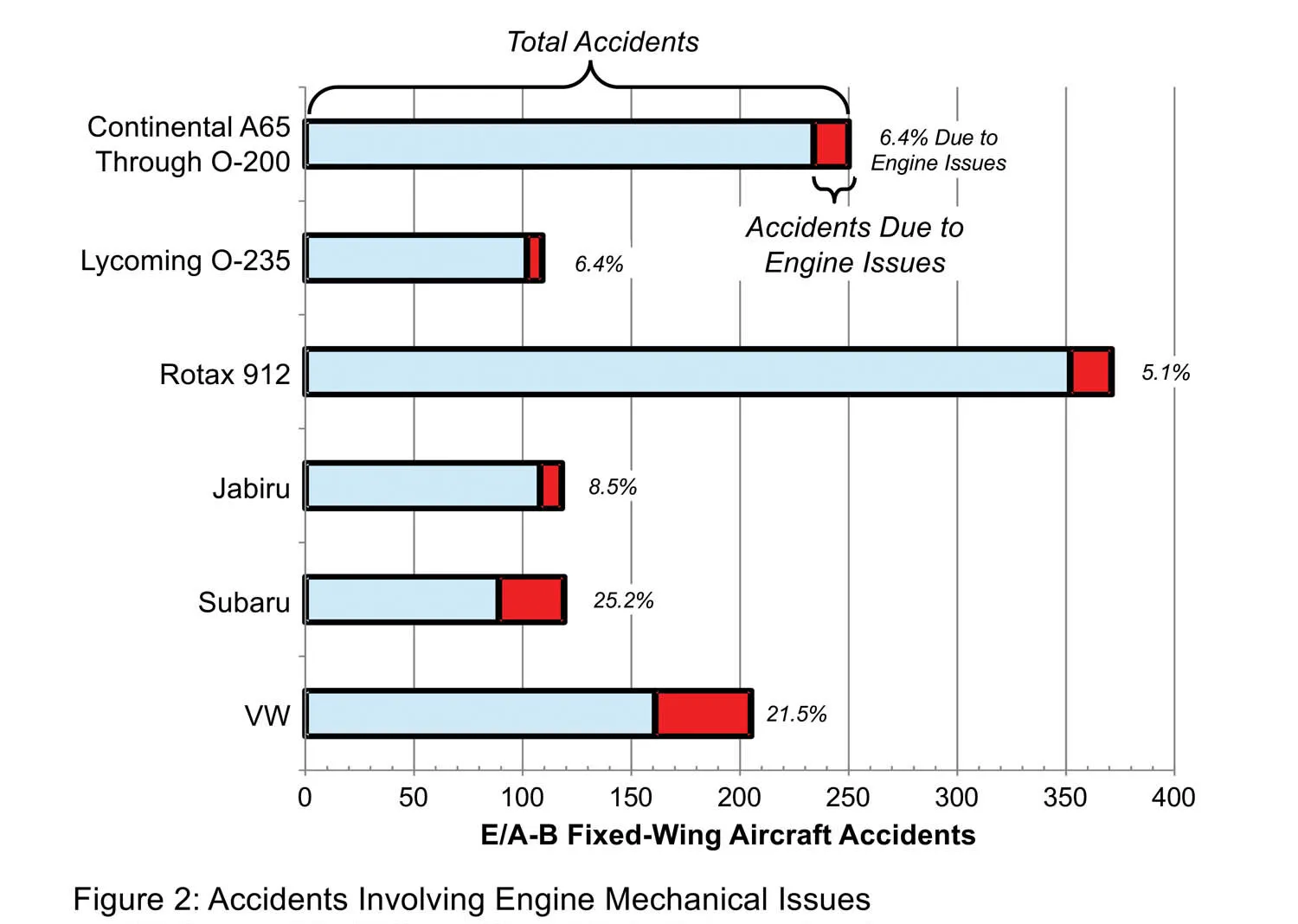

Figure 2 shows the results. The full length of the bars shows the total number of accidents that occurred to E/A-B aircraft with that type of engine. The red “tip” shows the number of accidents that were due to mechanical failure of the engine. The percentage at the end of the bars shows the ratio of accidents due to the engines.

The Rotax 912 has the lowest rate of all engines examined.

Breakdown Breakdown

Now, wait a minute. The 912 is (partially) liquid cooled and requires a radiator. It has a reduction drive and electronic ignition. All three are often problems on auto engine conversions. How do they stack up on the Rotax 912?

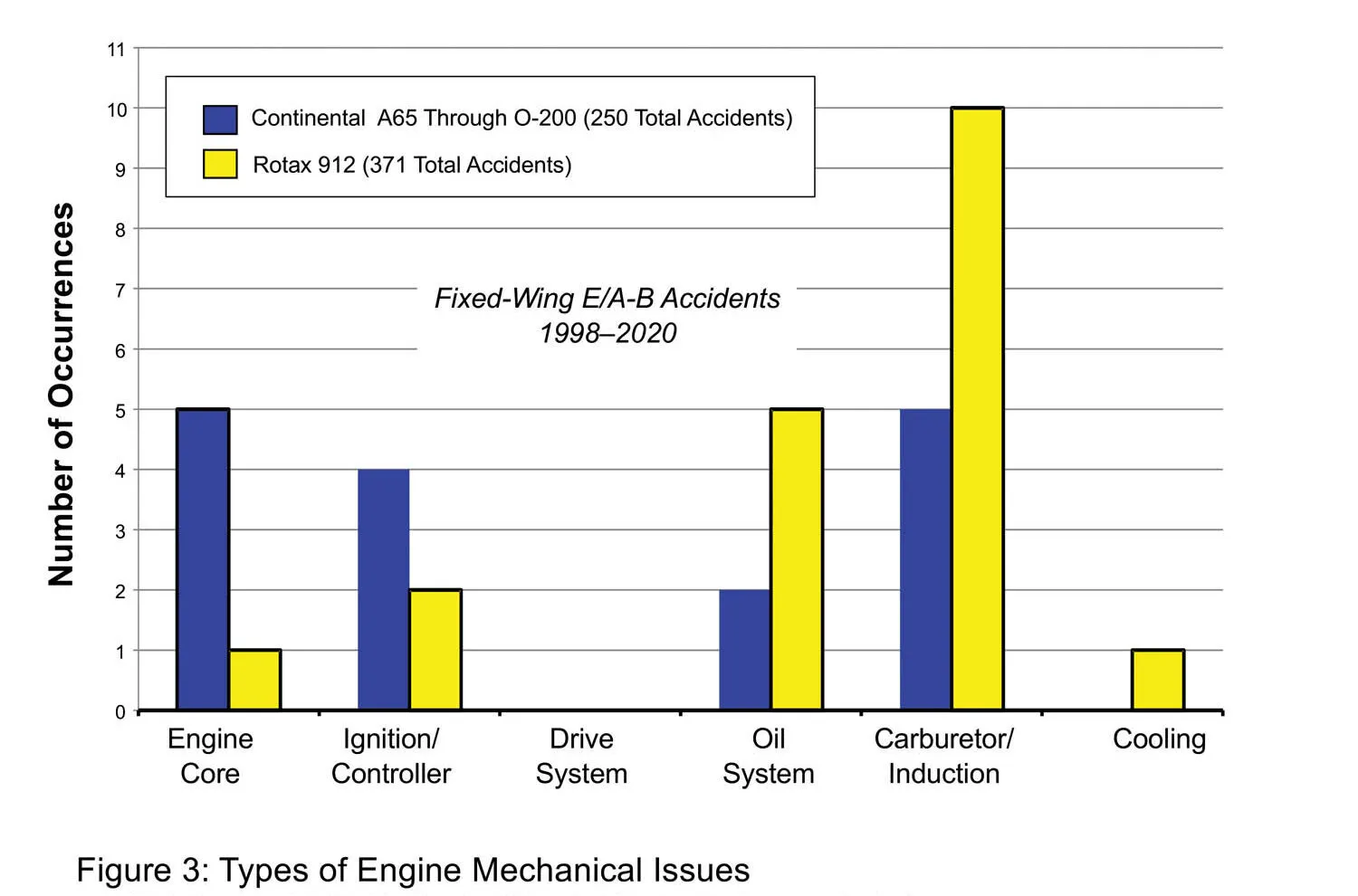

Figure 3 compares the number of engine issues in a variety of categories. Note that this is not the percentage—it is the actual number of cases in my database that involved each system. It totals 16 for the Continentals and 19 for the Rotax 912s. With these small sample sizes, percentages can vary too much. Let’s look at raw numbers, instead.

Cooling, ignition and gearbox issues? No E/A-B Rotax 912 accidents at all attributed to the reduction drive, only one to the cooling system, and the Rotax electronic ignition saw half the number of problems of the conventional magnetos used on (most of) the small Continentals.

Only one of the 371 accidents involving fixed-wing E/A-B aircraft with Rotax 912s involved a failure in the core engine. That was a failed valve pushrod seal that had been removed and reused by the aircraft owner. The 912 saw no failures of the major components such as connecting rods or valves over the 23-year period examined.

Figure 3 shows us that if we have to pick at the Rotax 912, there are two categories to examine: issues with the oil system and problems with the carburetor or induction system.

Remember, though, that there are 50% more Rotax 912 accidents than our small Continental set. And the sample size, as I mentioned, is low. There were two small Continental-powered homebuilt accidents attributed to the oil system, for instance, versus just five for the Rotax set. The difference isn’t that significant.

And I’m not seeing any recurring failures. For the five oil system cases, two were failures of oil lines (one was builder error), one was trash in the oil tank (probably also builder error), a Kitfox owner installed the wrong oil filter and the final one is a “dual entry” for the reused pushrod seal (its failure led to a loss of oil).

For the carburetor/induction cases, other than three involving improperly secured carburetors or controls, there weren’t any common causes. In addition to those three, another couple of cases were directly related to maintenance issues.

Other Power Failure Causes

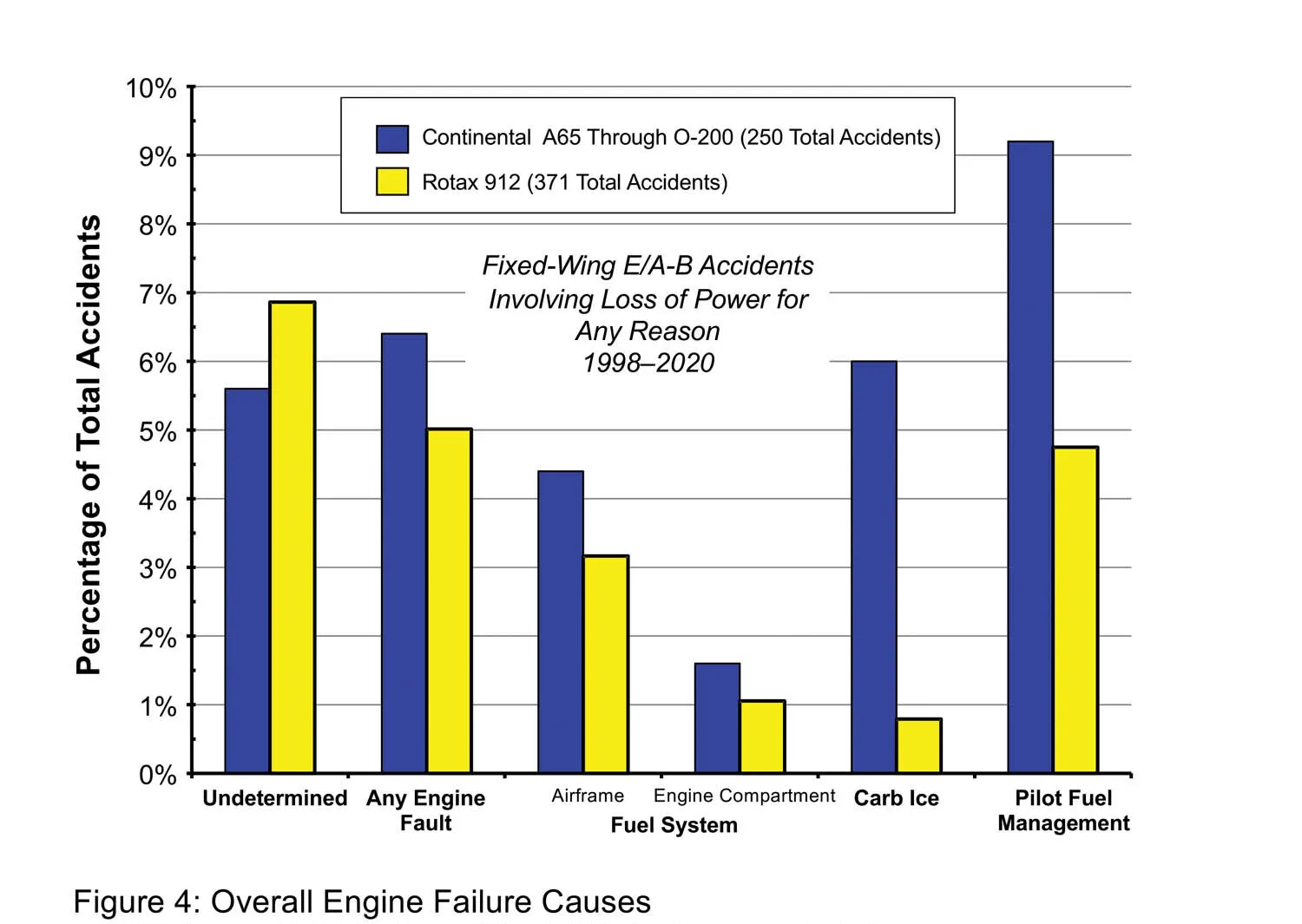

In 26 of 371 fixed-wing E/A-B accidents on aircraft carrying a Rotax 912, the aircraft lost engine power but the NTSB was unable to determine why. That’s about 7% of all the 912-powered accidents. It’s a little higher than the small Continentals—14 out of 250, or 5.6%, versus 26 out of 371 for the Rotaxes.

Why? Likely it’s probably just due to the NTSB investigator’s familiarity with the small Continentals. They may be more experienced at figuring out failures of those well-known engines.

The small Continentals have about five times the rate of carburetor-ice-related accidents. Some 912s are fuel-injected, but in the other models, the carburetors are snugged up to the warm crankcase. Continental’s updraft system isolates the carburetor from engine heat, making them more reliant on separate heating of the incoming air.

Curiously, aircraft powered by the small Continentals suffer power failures due to pilot mismanagement of the fuel twice as often as those carrying Rotax 912s. I’ve no good explanation for this. It’s possible, as a more-modern engine, aircraft carrying Rotax 912s might be more likely to include automated fuel monitoring systems. These could be giving pilots more insight into the actual fuel state of the aircraft.

The Bottom Line

For years, folks have complained that traditional aircraft engines need to be replaced by powerplants using modern technology.

As far as the small Continentals are concerned—well, the replacement is here. Data shows the Rotax 912 has better reliability than the traditional workhorses.

However, our “Continental” category suffered by lumping a number of different models together. Looking just at the O-200, the Rotax 912 and the O-200 have nearly identical statistics.

The downside? Cost. I’d love to replace the C85 on my Fly Baby with a 912, but the four-stroke Rotaxes start at about twice what my airplane is worth. For that matter, so do the brand-new O-200s.

When you think about it, though, that’s the way it was in the early homebuilding days, too. Few, if anyone, bought a brand-new C85 to bolt onto the front of a Stits Playboy. Those wanting engine reliability at a budget opted for good used engines.

It’s not an impossible option for those interested in Rotax 912s. Used engines are available. It may be a hard way to look at it, but the more Special and Experimental Light Sport Aircraft that are added to the registry, the more used Rotax 912s will eventually wind up for sale.

The nice thing is, the engines have been around for quite a while. There are a lot of online resources for troubleshooting, including dedicated factory support.

Continental vs. Rotax 912? If we include only the O-200, the two competitors are neck and neck. Maybe the baton hasn’t been passed, but both engines are marvelous options.

Photos and illustrations: Ron Wanttaja.

This article originally appeared in KITPLANES. For more great content like this, subscribe to KITPLANES!

Yes, but the Rotax has the attraction of being around 10 kg, from memory, lighter. Which was a big plus when most of Europe had a 450 kg max take off weight rule for microlights, although that has now been relaxed a bit.

Strange that it is still seen as new, after all these years.

Look at the SLSA accidents in the Rotax 912. You will find a string of valave failures. The 912 isn’t bad, but we’re not there yet.

Two points, one on the oil system and one on the induction system.

Oil. On the Rans S7, the oil tank is trapped behind the motor mount, so to clean it out you have to detach the motor mount from the firewall or engine from the mount. It is not possible to visually evaluate the amount of sludge (from using 100LL) in the oil tank, and because removing it for disassembly and inspection is so onerous, that action is probably deferred.

Induction. The carburetors require an inspection every 200 hours, necessitating removal, disassembly, and replacement of certain components as necessary. Contrast that to a Precision MA-4-5 that only gets inspected internally/overhauled every 2000 hours. Again, it’s easy to defer maintenance when the engine is “running fine”.

Well said.

Paul made a statistic study about reliability between Lycomings and Rotaxes and Lycoming had a way better number than what is shown here. I do not believe Rotaxes are more reliable than Lycomings. Period. No matter how much marketing is thrown out there.

As Vince points out above, my data doesn’t include aircraft licensed as Special or Experimental Light Sport…nor, of course, does it include the data from the certified engine world. It’s solely from the Experimental Amateur-Built world.

“Reliability” can be sliced up in various ways. My process looks at engine failures in ten different ways, from loss of power due to ANY reason (including running out of gas) to engine failures where the NTSB was unable to determine the cause. Throw builder or maintainer error into the mix, and one can generate a wide range of statistics.

However, the data should produce results that are *internally* consistent. No matter which way you slice it, the reliability info for the Continental O-200 vs. Rotax 912 should be relatively the same.

For this article, I tallied the engine failures caused by mechanical issues related to the engine, including those builder or maintainer induced. It does not include the cases of undetermined engine failure. The Rotax 912 came out ahead of the Lycoming series, and neck-and-neck with the O-200. I have 402 Rotax 912 EAB accidents in my recently updated database, and 526 accidents occurring to homebuilts that have Lycoming O-320s. The O-320s come out good, no question…but still slightly worse than the Rotax 912s. Again, in Experimental Amateur-Built aircraft, which is all I analyze.

I do these analyses out of pure curiosity. For me, the fun comes from discovering unexpected results, then beating the crap out of them to convince myself that the discovery is real. Not just an artifact of my analysis method or wishful thinking. In the 20+ years I’ve had this hobby, there have three times where I’ve rocked back in surprise at the result.

The Rotax vs. Continental comparison was the third. DIDN’T expect the 912 to come out this good. Had an inkling from prior analyses, but it wasn’t until earlier this year that I split my database out to make it easier to view specific engine models.

Very interesting,the older engine designs still more or less unbeaten

Another thing to consider is that the majority of Rotax 912 series engines in use were new when installed, while the majority of legacy engines were used, and in some cases, backyard “overhauled”.

My ex-wife came uncomfortably close to a catastrophic engine failure over a congested area because a backyard builder used common silicone sealant (and way too much of it) to assemble the engine.

Globs of silicone eventually caused the oil transfer valve of the inverted oil system to stick open, causing a complete lack of oil circulation.

She made it back to the airport, but the #1 connecting rod was about to depart the crank journal and exit the crankcase.

Interesting and not too surprising results. A few additions/corrections/speculations … First, while the location of the 912 carbs above the engine may contribute to fewer icing problems, the main reason is the “constant velocity” 1980’s motorcycle design Bing carburetors, which are much less prone to it in the first place. With that comes “automatic” mixture compensation which eliminates misuse of that knob, either by running too rich and loading up plugs, or too lean from forgetting to enrich upon descent. Too, a CV carb will not stumble when the throttle is opened fast and has no need for an accelerator pump to overcome the sudden drop in manifold pressure.

Next, water-cooling is a general non-issue in part because it’s also air-cooled. It will run long enough to land after loss of water and may even be undamaged if the problem is noticed in time and power is reduced accordingly. Otherwise, having water-cooled heads is a huge advantage. Cylinders do not have to be tapered like with Ly-Con engines so all clearances are much tighter. I’ll burn perhaps 1 liter (of 3 total in the system) per 30-40 hours and need to clean the belly once a year or so. With most 912 installations, overheating from prolonged idling on the ground is not a factor and neither, within reason, is shock cooling in the air.

Ignition? Super reliable compared with clunky magnetos, plus being far safer on the ground. It takes 200+ rpm for the plugs to fire, so moving the prop (always in the direction of engine rotation!) on the ground will never result in amputation. There are no points to wear out, no drive gears or moving parts and no timing to adjust. Total win in that regard.

I was surprised that the number of fuel starvation accidents is small by comparison, but perhaps it makes sense in that it burns so little. Max cruise power @ 5500 rpm, yeah about 5.5 gph. But reduce power and it gets really good. My last 60 hours cruising @ 4,600 rpm, about 85 kt, averaged 2.65 gph.

Gearboxes basically never fail. A worn out one will rattle like an angry snake, but it won’t break. “Rotax” came from the original company, “Rotating Axle”. They know how to do this.

The engine “core” is, unless radically abused, wear-free. In class, we broke a 2000 hour engine for the first time. Clearances were near-new.

The biggest threat to safety/reliability with 912’s is lack of education. It’s, by old aviation standards, a weird engine. Typical A&P’s know little or nothing about them and the schools don’t teach Rotax, in spite of there being about 50,000 912/914 series already in service. The company fights this with excellent hands-on 2-day seminars on Service, Line, and Heavy Maintenance, open to anyone. Also, with one exception, all factory manuals are available online and routinely updated. Which brings up another point: a 912 of today is quite a bit improved over one of 10 or 20 years ago. They are active in improving the product. LyCon? Not so much, especially with the smaller engines.

Cost? Yeah, they’ve gotten expensive, largely because they’re so good. The airboat market sets the bottom of the market for a 2000 hour 912 at about $5,000. Overhaul yourself? Cylinders okay perhaps, but Rotax does not provide information about inside the case. The crank is pressed together and they claim it can only be split and reassembled with specialized factory equipment.

Very educational writing about the 912. Helps my understanding of those engines a lot, thanks!

Have had very limited experience with a 912( a Ximango motor glider) but was very impressed with the engine. It ran very smoothly,didn’t leak,and was easy to start,hot or cold. It would be interesting to see if Rotax would hang two more cylinders on it and make a small 6 of around 200 hp to replace some of the old O-300 powered classics like the C170 and Aeronca Sedan.

All the above have validity..

However, there are 3 letters every pilot/operator should work with…

AME

Simply said … your local Aircraft Maintenance Engineer.

Safety First!!