By Russ Erb

This story originally appeared in KITPLANES.

After telling the following story to many other pilots, I came to a conclusion that my flight instructor never told me. For that matter, I’ve never read or heard about it in KITPLANES, EAA, AOPA, AVweb or anywhere else in the aviation press. I know a lot of general aviation pilots and I work with a lot of Air Force pilots, especially test pilots, and so far this has held true with every one of them. The dark little secret that no one talks about is this: Every pilot with a significant amount of flight time has at least one story of when they were terrified in an aircraft.

This is our story.

The Plan

The “fun” began on Saturday, October 19, 2019, on what was supposed to be an enjoyable VFR pleasure flight from Rosamond Skypark (L00) over Tehachapi Municipal (KTSP) to Kern Valley (L05). Kern Valley is a lovely airport nestled by Lake Isabella on the east side of a fairly narrow canyon. The downwind pattern leg is flown northbound on the west side of the canyon, and the base turn is around the far side of a hill that causes you to lose sight of the airport for a while. Don’t worry—it will still be there when you turn final. Your reward for this slightly challenging approach is a parking ramp that isn’t level and a wonderful breakfast with some amazing pancakes.

Karl Major and I were to meet at 7 a.m. for an early morning departure. The nearest Terminal Aerodrome Forecast (TAF) was from Fox Field (KWJF), 8 nautical miles south of our departure airport. The wind speed in the morning was forecast to be in the single digits, increasing into the double digits by 2 p.m. As we were flying a taildragger, any winds much into the double digits rapidly become “ugly,” so we planned to leave early so we could get back early. This plan would avoid the need to demonstrate any exceptional piloting skills on the landing. Sadly, we failed to check the winds aloft forecast.

The Aircraft

The aircraft was a four-seat Bearhawk, N6786E, serial number 164, which I had scratch built from 1996 to 2008. The engine was a Lycoming O-540-E4A5 (260 hp). Total time on the airframe was 686.5 hours. At the time of the incident, the gross weight was 2300 pounds.

The reason I can tell you the following story in such detail is because the Dynon EFIS-D10A continuously records flight data at 1 Hz and always has a record of approximately the last two hours of flight. In this case, it was my “black box” flight data recorder. The data was downloaded shortly after returning the airplane to the hangar. It included pressure altitude, indicated airspeed, outside air temperature, load factor and Euler angles (pitch, roll and heading). The EFIS-D10A also records WAAS GPS latitude, longitude, ground speed and ground track as received from the Garmin GNS 480. The EFIS-D10A displays winds but does not record winds. Winds reported here were calculated post flight from true airspeed, heading, ground speed and ground track.

The Aircrew

Any exciting “There I Was” story should be seen in the context of the aircrew’s experience level. I was sitting in the left seat. I had over 800 hours of airplane time and have been in the left seat for all of the flight time this Bearhawk has accumulated. I also had over 1100 hours of glider time, mostly as an instructor. I am a flight test engineer graduate of the USAF Test Pilot School (Class 89B), and had over 1600 hours as a flight test engineer.

In the right seat was Karl Major, who had over 8100 total flight hours, with over 500 hours of general aviation flight time. Karl is a test pilot graduate of the USAF Test Pilot School in Class 90A, the class immediately following mine. Karl and I worked together on the MC-130H Combat Talon II flight test program and have taught together at the USAF Test Pilot School for far more years than we care to count.

(Spoiler: Having lots of experience does not protect you from having way more excitement in the cockpit than you want. However, it can help you to deal with that excitement appropriately.)

Turbulence and Mountain Wave

Before getting into the details of what happened, let’s review the definitions of turbulence intensity from our favorite bedtime reading, the Aeronautical Information Manual.

Light: Momentarily causes slight, erratic changes in altitude and/or attitude.

Moderate: Greater intensity. Changes in altitude and/or attitude occur, but the aircraft remains in positive control at all times.

Severe: Causes large, abrupt changes in altitude and/or attitude. Large variations in airspeed. May be momentarily out of control.

Extreme: Aircraft is violently tossed about and is practically impossible to control. May cause structural damage.

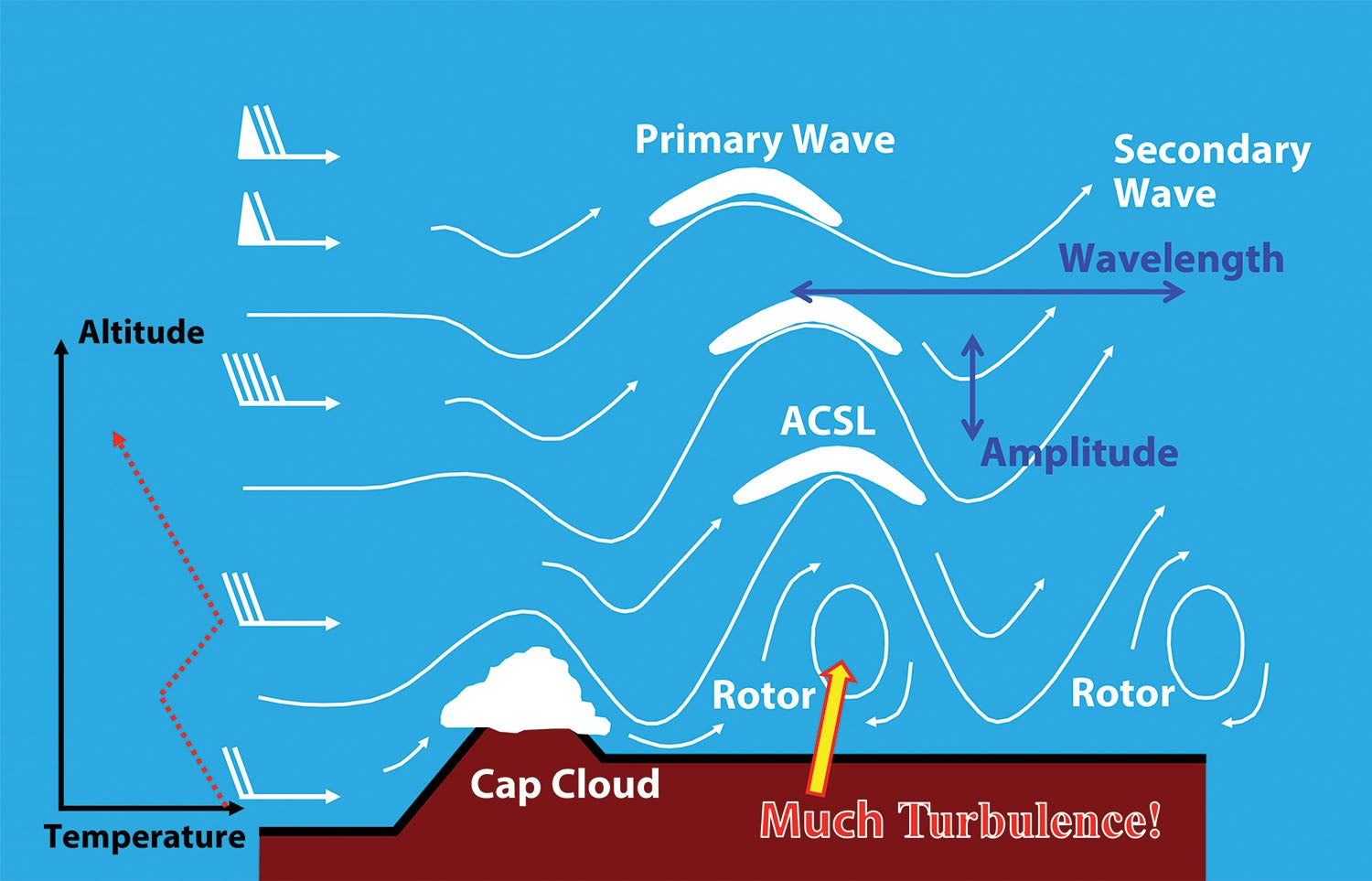

Mountain Wave is caused when a strong wind (typically greater than 30 knots) of stable air blows more or less perpendicularly across a mountain ridge. The wind needs to be generally in the same direction at all altitudes and increasing in speed as altitude increases. Because the air is stable, the wind flows down the lee side of the ridge and then bounces up and down in a standing wave. Glider pilots love mountain wave because the rising parts of the wave produce a steady supply of lift. However, the wind speed near the surface may be significantly less, approaching calm conditions. This significant wind shear can set up some terrific turbulence, especially under the crest of the wave, as shown in Figure 1. In the space under the crest, the air has no place to go, so it starts twisting in a giant horizontal vortex. This area is known as the rotor. If there is sufficient moisture in the air (humidity), the lowered pressure in the rotor will cause the temperature to drop below the dew point and the moisture will condense into a roll cloud. Roll clouds are very nice indicators of where you shouldn’t fly, unless, of course, you’re in the desert and there isn’t sufficient moisture to form a roll cloud.

Encounter With Extreme Turbulence

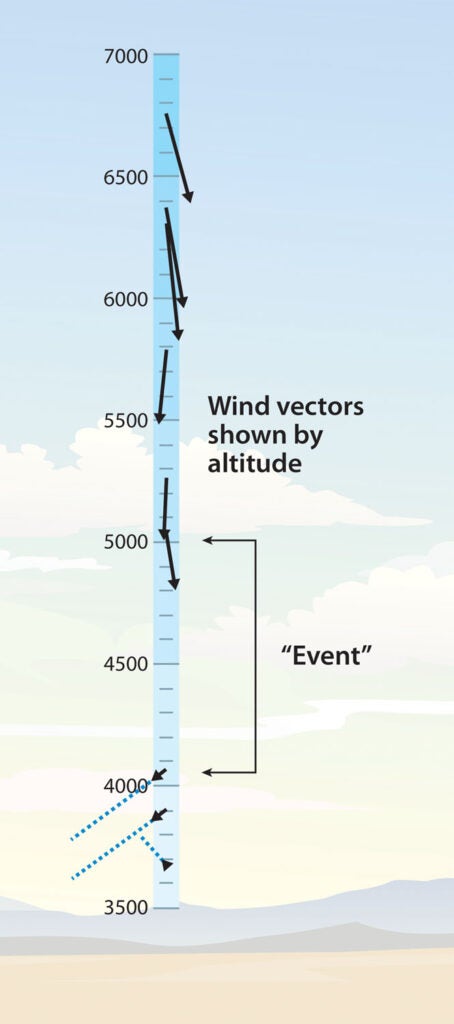

The flight to Kern Valley was nominal and without incident. After breakfast, we departed Kern Valley for the return to Rosamond. After overflying Tehachapi, we turned southeast to cross the mountain ridge and begin the descent into Rosamond. Figure 2 shows selected points along the flight path, progressing from north to south (top to bottom). The dots show the aircraft’s position. The vectors (arrows) show wind speed and direction. For clarity, the numbers show the wind speed in knots.

Near the top of Figure 2, we checked the ATIS at KWJF (8 nm south of L00), which reported calm winds. We noted the high wind speed displayed in the cockpit and discussed the possibility of turbulence from wind shear. I had flown this same route years ago with calm winds reported on the ground and even higher wind speeds at altitude, and had descended with surprisingly little turbulence. Approximately six miles north of Rosamond, I made a radio call announcing that we were approaching the airport. A pilot on the ground preparing to take off replied, reporting that the windsock was limp.

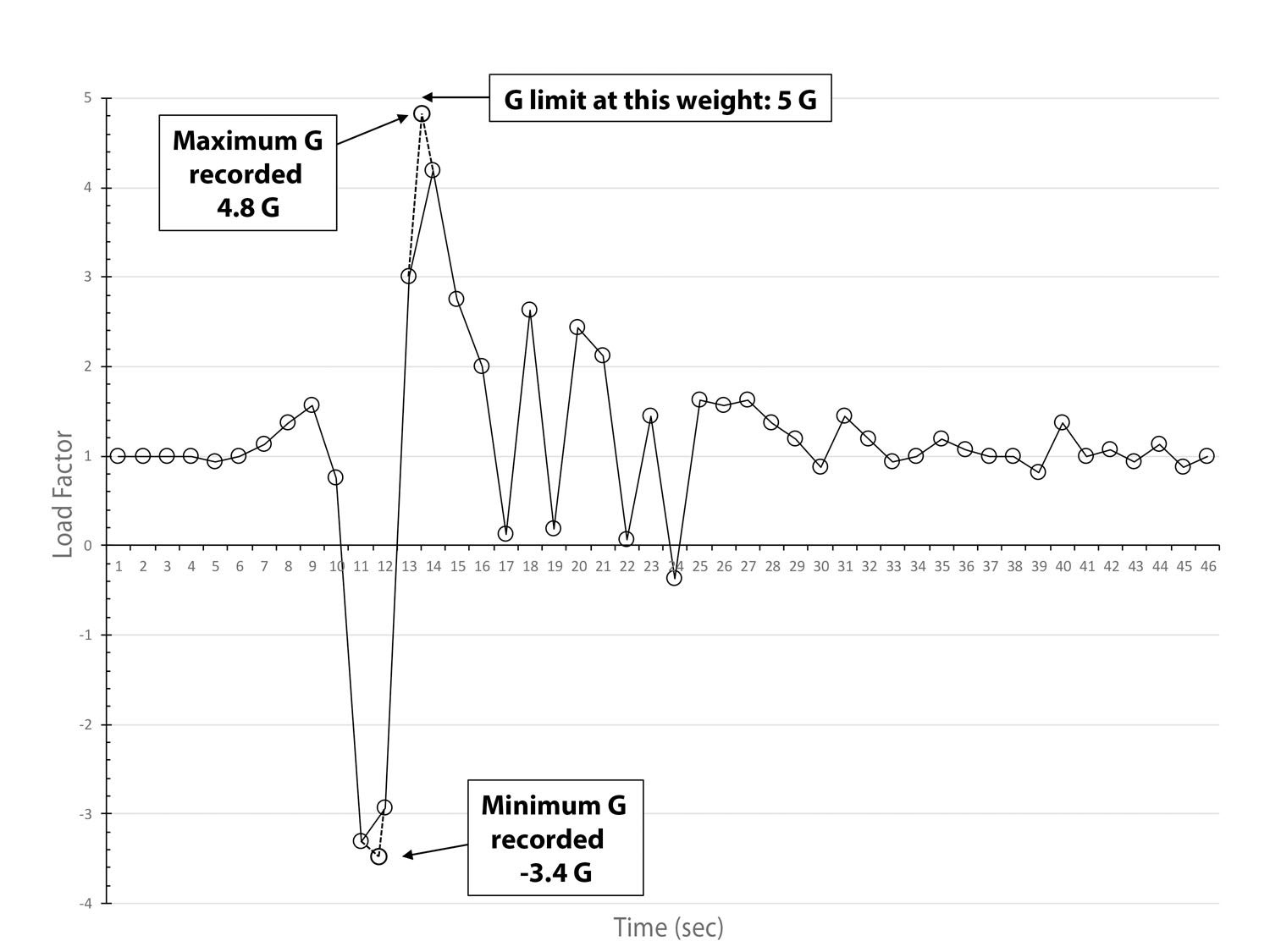

At the red line in Figure 2 labeled “Too much excitement” we encountered extreme turbulence, presumably caused by an unseen mountain wave rotor. The turbulence caused an abrupt pitch down, resulting in a peak negative load factor of -3.4 G, as shown in Figure 4. Almost immediately, we pitched up to a peak positive load factor of 4.8 G. The remaining excursions occurred while we struggled to regain control of the aircraft and return to level flight.

Karl was flying at the time (10:42 a.m.) of the turbulence encounter. Before the pitch down, he noticed the airspeed in the descent going above 135 knots, which is the beginning of the yellow arc on the airspeed indicator. Thinking this was faster than prudent, he started raising the nose to slow down when it abruptly pitched down. His first thought was that the tail or a wing had abruptly fallen off. Following Bob Hoover’s advice, “Fly the airplane as far through the crash as possible,” he decided to continue trying to fly the airplane. His headset departed his head during the pitch down. Pulling on the stick, he noticed that the nose started to come up and that there was still some amount of control. Being an accomplished test pilot, he pulled on the stick enough to get the desired response, but intentionally did not pull to the stop, to minimize the chance of an over-G. The excitement wasn’t over yet. Three to four seconds after the initial pitch down, the nose was seeking the ground again. By this time Karl had processed in his mind the need to reduce the throttle. However, I usually took care of engine management, so he hadn’t touched the throttle all day. He pulled on the knob nearest to him, which was the mixture. Sensing incorrect response for a throttle, he pushed it back in and went for the next knob, the propeller. Again, he sensed improper throttle response and pushed it back in. Karl never made it to the third knob (the actual throttle) because the airplane was starting to recover. After a few more less-significant oscillations, the pitch angle was near level and recovery was declared. Seeing that I was now on the flight controls, he passed control (“your airplane”) and began a “battle damage assessment,” looking around to see what was still there and what was damaged. Finding the two headsets, he replaced his own headset and then put the other headset on me.

As for me, I have absolutely no memory of the initial pitch down. I don’t know why, but I don’t. At some point during or after the following pitch up, I “woke up” to an incredibly loud noise and a windshield full of the ground below. Not knowing what was going on, but seeing a windshield full of dirt, I instinctively grabbed the stick and tried to bring the nose up to level. The thought that passed through my mind was, Is this how it all ends? I saw Karl reaching for the throttle, and reasoned that he would retard it, which seemed like a good thing to do. The stick did not seem to have the same pitch response as usual, but eventually the airplane leveled out. Because of the noise, I thought the windshield had blown out, but there was no wind in the cockpit. I reached forward and touched the windshield to confirm that it was still there. The source of the noise finally became apparent when I felt Karl trying to put my headset back on my head.

It turned out that we were so in sync with our stick inputs that neither of us realized the other was on the controls. I asked “What the #*%@! happened?” Karl, surprisingly casually, responded: “We just flew through a rotor.” Based on the previous wind readings, I thought that this was a reasonable answer. I started looking around the instrument panel trying to assess the aircraft’s condition. The #2 EGT had gone off-scale low. Was the pitching so violent that a cylinder fell off? Listening to the engine confirmed that it was still running, perhaps a little rough, but still producing power. The engine problem could be addressed later. Since the airport of intended landing was now close by, I ran the before-landing checklist, which included moving the mixture forward to best power. The engine had a surge of power and the #2 EGT returned. The problem was that Karl had over-leaned the mixture by mistake when reaching for the throttle. After flying level for a few minutes to calm down, I entered the pattern and made an uneventful landing.

During final approach, I noticed an unfamiliar electronic “beep-beep-beep” and commented on it. I decided to momentarily ignore the beeping and continue to concentrate on the landing. After landing, the beeping seemed to get louder as the background noise diminished. Pulling off the runway, I determined that the carbon monoxide detector was the source of the beeping. It was unfamiliar because it had never triggered before. A quick check confirmed that the cabin heater had been and was still shut off. We opened the cockpit windows, and the CO detector stopped beeping within 10 seconds.

Later we learned that another pilot reported flying in the same general area 7 hours later in an RV-10 and had encountered turbulence strong enough to bounce his head off the canopy.

Figuring Out What Happened

As career Air Force flight testers, our natural response (after having some time to calm down) was to use whatever data we had to try to understand what happened. I downloaded the flight data from the Dynon EFIS-D10A and looked for the incident. It was easy to find simply by graphing the load factor against time and looking for the huge spikes. Putting the data into a spreadsheet, I calculated the wind speed and direction that would have been present in flight.

These wind values were plotted at selected locations along the flight path over a Google map image at the location where they were measured, as shown in Figure 2. At the upper left corner of the figure is a large mountain ridge running northeast-southwest. The winds at altitude were in excess of 30 knots and blowing roughly perpendicular to the mountain ridge. However, as mentioned before, the winds on the ground were reporting calm. This was a classic setup for significant wind shear caused by mountain wave.

Figure 3 shows the same wind vectors, but in a somewhat odd presentation. The tails of the wind vectors are at the altitude that the wind was measured. The direction of the wind vector shows the direction (heading) of the wind with true north being up. That is, the wind was not blowing down in altitude, but was blowing from the north. The point to notice is that the winds were very strong above the event and very light below the event, with up to a 90° shift in direction. This is significant wind shear, and where there is wind shear, there is usually turbulence.

Figure 4 shows the time history of load factor during the event. The horizontal increments are one second each. The maximum positive and negative load factors were not recorded in the data file, but were captured on the EFIS-D10A screen. The load factor shows the aggressive pitch down, followed immediately by an aggressive pitch up. It is not clear at what point the extreme turbulence subsided, although Karl thought the violent part of the upset lasted at least 1½ cycles. The subsequent oscillations show how we struggled to get the oscillations under control and return to level flight.

At the time of the incident, the gross weight of the Bearhawk was 2300 pounds. According to the designer, the maximum load factor allowed at this weight is 5 G. The maximum load factor recorded was 0.2 G below the 5 G limit. No negative load factor limit was published. However, if one was published, it would probably be less than -3.4 G.

Incident Reconstruction Video

Even with experience, it can be very difficult to look at traces of attitude data and recreate in your mind what the event actually looked like, especially when the perturbations were large. It is much easier to understand what it looked like if those angles can be transformed into a 3D rendering. I didn’t have an easy way to do this, but I managed to cobble together a solution. For the rendering, I used an Euler angle visualization tool by Chris Tralie.

To increase the resolution, I did a linear interpolation between data points at each quarter second. This resulted in four times as many data points and made the resulting video less jerky. I typed the Euler angle values into the above tool 184 times (4 x 46 data points). Each of these frames was screen captured, cropped and loaded into a video editor. Each frame is shown for seven video frames, which is 28 frames per second. As I was finishing up, I realized that 4 does not divide very well into the NTSC standard 29.97 frames per second, but it was too late. The result is that a 45 second incident is shown in 43 seconds, which is still close enough for you to understand what happened. The other limitation was that the only 3D model available was an Airbus A380. Suspend your disbelief and just pretend that a Bearhawk looks like an A380:

Inspection

Immediately after landing and returning to the hangar, the Bearhawk was grounded pending a major inspection. There is no published condition inspection checklist for the Bearhawk, and there most certainly is not an “extreme turbulence encounter inspection” checklist either. Therefore, I started with my personal condition inspection checklist and tailored it with a good amount of thinking about what might be affected in such an event. I have detailed here what I looked at so you can get a feel for the extent of an inspection that I felt was appropriate. I reported my results to Bob Barrows, the Bearhawk designer, and he considered this inspection sufficient.

Wings

The first inspection of the wings was to inspect for new wrinkles in the skins. I reasoned that any permanent deformation of the structure would result in noticeable wrinkles in the skins. No wrinkles were found. Sighting along the spars showed no bends. The wingtips were removed to look through the inside of the wings. All of the lightening holes were still aligned.

I removed access panels to inspect the flight control system for any damage. No damage or deformation was found. I inspected the aileron hinges and flap hinges.

I removed the wing strut fairings for inspection. The wing struts were still straight, in spite of the negative G spike. I inspected all of the end fittings for damage. I used a borescope to inspect inside the struts (and you thought borescopes were just for engine cylinders!). I inspected the straps that connect the wing struts to the wing spars. I inspected the fuselage strut attach fittings and removed the fairings to inspect the landing gear strut fittings at the fuselage. No damage was found.

I removed the wing root fairings and inspected the wing to fuselage attach points. No damage was found.

I did not open the fuel tank bay, which requires removing about 150 screws (each). Since there were no obvious fuel leaks and the drain plugs, vent tubes, filler caps and fuel tubes all showed no dislocation from normal, I assumed the tanks were undamaged.

Fuselage

Our inspection immediately after the event identified small tears in the fabric that forms the cockpit ceiling. These were assumed to be caused by loose items such as the spare tailwheel striking the ceiling during the initial pitch down. This damage does not affect the airworthiness of the airplane and will be repaired at some time in the future.

The immediate post-landing inspection also identified that the mount for the aera 510 GPS was bent up, presumably from being bumped by Karl’s knee. This was repaired simply by unbending the sheet metal mount.

I inspected the wing attach brackets and wing strut attach brackets for any cracks or deformation. The load paths across the fuselage between the attach brackets were also inspected for any cracks or deformation. No damage was found.

When I inspected the windshield, I found the top edge of the windshield had popped out of the upper channel on the fuselage, presumably from fuselage or windshield flexing at some point. I loosened the windshield, reinserted it in the upper channel and reattached it. No damage was found in the Plexiglas of the windshield.

I inspected the fuselage tubes for straightness, including those under the instrument panel and those behind the aft cabin bulkhead. No damage was found.

The hat switch on the right side stick grip was broken off. A replacement switch was ordered and installed.

Tail

My initial inspection of the tail looked for wrinkles in the fabric skin caused by deformation. No wrinkles were found. All of the tail tubes were as originally built. I removed the access panels to inspect the tail attachments to the fuselage and flight control connections. The leading edge strut for the right horizontal stabilizer was slightly bent. After removing the strut, I found the strut to be bent out of straight by 0.4 inches at the center of the strut. I carefully bent this strut back to straight. The left side strut was found to be straight after removal. Upon reinstallation, I found the fuselage mounting tabs at the bottom of both struts were slightly misaligned, causing a slight elastic bend in the struts when installed. A well-placed whack with a mallet bent these mounting tabs just enough to remove the bend from the struts. Prior to the incident, my normal preflight inspection had not included checking these struts for straightness. Because of this oversight and the slight misalignment of the tabs, I could not determine if the bend in the right strut was caused by the incident or was a preexisting condition.

Engine

I checked the engine mount for straightness. No deformation was found. The rubber Lord mounts looked no different from the last condition inspection. I checked the exhaust system for integrity, especially in light of the carbon monoxide detection upon landing. No damage was found in the exhaust system.

Functional Check Flight

After completing the inspection, I cleared the aircraft for return to flight. The test flight revealed no problems. No further carbon monoxide detections have occurred. My assumption is that during the gyrations of the event, some of the exhaust gases were entrained into the cockpit and became trapped there. Such an event has not occurred on multiple subsequent flights.

Resulting Changes

For many years I have flown around with items unsecured in the back of the airplane. I had no reason to fly at anything significantly less than 1 G, so why should I worry about it? Now that I have had one upset to -1 G in 2009 and one to -3.4 G in 2019 (maybe I should be concerned in 2029?), I have taken steps to ensure that more stuff stays where it is supposed to be.

The oxygen bottle (when installed) has always been secured by clamps to the floor under the rear seat. The spare tailwheel that I carry (main gear 6.00×6 tires can be found at almost any FBO—tailwheel tires and tubes are much rarer) is now kept in a mesh bag attached to the rear seat leg with a carabiner. The control locks (made from 550 cord and plastic cutting boards) are kept in a repurposed makeup bag, also now fastened to the rear seat tie-down ring with a carabiner.

A set of emergency tools were stored in a Rubbermaid plastic container under the pilot seat. Survival gear was stored in a similar container under the copilot seat. Both were tied off to the aircraft structure to prevent them from moving around. During this incident, the tool container was forced open, allowing some of the tools to float around the cabin. The handles of the containers are now tied together with avionics lacing cord to prevent their unintentional opening.

For larger loads, cargo nets were purchased from Harbor Freight for less than $10 each. These can be connected to tie-down rings with carabiners. Currently my rear seat is attached with four eyebolts that also serve as tie-down rings. An additional tie-down ring is at the bottom center of the rear bulkhead. This left the two rear corners without good tie-down points. The solution was to fabricate a tube with eyebolts at each end to span across the floor at the rear bulkhead. The tube is held down by a bolt or eyebolt through the current tie-down location in the center. The cargo nets are able to work whether the rear seat remains installed or not.

What Does This Say About the Plane?

Bearhawk N6786E momentarily reached a positive load factor of 4.8 G at 2300 pounds gross weight, just under the stated limit of 5 G at this weight, with no structural damage. While no negative load factor limit is specified, anything less than 0 G is impractical with a carbureted engine with no inverted oil or fuel system as the engine will not continue to run at these conditions. Bearhawk N6786E momentarily reached a negative load factor of -3.4 G with no structural damage, which should be well in excess of any reasonable expectation. Of particular note was that the wing strut was a narrow column in compression at this moment and showed no signs of buckling.

While it is rare that a non-aerobatic airplane would undergo such an extreme structural test, and certainly not in such an unplanned manner, it can be seen that the Bearhawk is designed with a strong structure to withstand expected loads and is also very robust to take unexpected loads as well.

What About the Crew?

It is fine to look at how the airframe weathered this incident, but it is also important to examine how it affected the crew. The physical effects were minor. A couple of days later I noticed a bump on my head that didn’t hurt and I didn’t remember how it got there. Karl had a small cut on each leg, presumably from his legs striking the bottom of the panel or the GPS mount during the negative G spike.

The mental effects will vary from person to person. Karl experienced time dilation, feeling that the event was far longer than the 28 seconds of bucking that we actually experienced. He claimed to have seen a bunch of stuff floating in the cockpit behind me, even though that would have only lasted about 2 seconds. He thus had a very heightened awareness of what was going on, if not why it was going on. For me, since I missed the first few seconds of the event, I started out by trying to figure out what was going on and quickly what to do about it.

When the airplane was finally back under control, I knew that figuring out why it had happened could wait until later. The first priority was to ensure the airplane was in a safe configuration. I did this by running the before landing checklist. If we had been farther away from the airport, I would have run the cruise checklist. Procedures can be comforting—running a checklist has the benefit that when it is complete, you can tell yourself that everything is as it should be, even if it doesn’t feel that way. For the landing, I cleared my mind of everything except carefully following the same procedure that had gotten the airplane on the ground safely so many times before.

Once we were safely on the ground and shut down in front of the hangar, we were able to relax a bit. However, this relaxation released all of those thoughts that run through your head after a traumatic event. We put the airplane away and then I focused on driving us safely 2.5 miles to my house. I suggested that Karl come in and sit with me in the safety of my living room while we both recovered so that he could also safely drive home. Even an hour after the event, we still had effects, such as weak knees, fatigue, exhaustion, and ill feelings. The Air Force has a strong safety culture, which encourages frank discussion of unusual events for the purpose of improving safety. With this background, we found comfort in discussing everything we could about what had just happened. This also helped cement the memories so that we could share them with you. Don’t try to conform to some notion of the unflappable pilot and act like nothing happened—it won’t help you or anybody else.

How Did We Know What to Do?

Training and experience matter. You need to get some before you need it. It is well known that when things go pear-shaped, your immediate response will be, without thinking, to do whatever you have done before in a similar situation. Therefore, it is important to have the experience of responding properly, but generally we avoid putting ourselves in hazardous situations just to practice what to do. This is where training becomes important, learning to work through simulated emergencies. I find it amazing how difficult the simple task of recognizing an emergency, finding the right checklist, then reading and executing the checklist can be, even in a simulated emergency, especially if you’ve never done it before. While it may sound counterintuitive, the feeling that you must do something quickly can actually slow you down. Many people have said “fast is slow, slow is fast,” meaning that it is better to respond methodically than to respond quickly. In multi-engine operations, I have always heard it stressed that both pilots must agree on which engine has failed before anyone feathers a propeller. There are far too many stories of rushing and feathering the good engine. Some emergencies can be simulated safely in an airplane; others are better practiced in a simulator. Aviation training devices (ATDs) are becoming cheaper and more available, and you should consider doing some emergency training in one, perhaps at your next flight review.

As for the subject aircrew, we are both professional flight testers and have been for a long time. In spite of what you may think from old movies, it would seem that one objective of our test planning is to make our flight tests as absolutely boring as possible. That is, the goal of flight test is to find issues without ever having to demonstrate our “superior” flying skills. We do this by predicting exactly what we expect to happen and then thinking of all of the things that can possibly go wrong. When we’ve identified what can go wrong, we form a plan—first for how to prevent it going wrong and second for what we will do if it does go wrong. Excitement comes when something unexpected happens, and we don’t like that kind of excitement. If we’ve done our preparation well, the actual flying is boring to an outside observer. That’s why you don’t see any realistic movies about test pilots.

We also spend a lot of time reviewing mishaps and what could have been done to prevent them. This is common for professional aircrews, be they in the military, the airlines or some other field of aviation. You can build this type of experience too. Besides working with a flight instructor, you can avail yourself of the excellent videos, courses and quizzes made available by AOPA’s Air Safety Institute. The FAA’s Wings program and FAAST programs are other ways to expose yourself to “what would I do” without actually being in danger. If you think safety is boring and you’d rather just go flying, you’ll probably find yourself in a scenario of compromised safety with no idea of what to do! I know of several times when I recognized what looked like an accident chain forming, and I took steps to break the chain. I can’t say for sure that an accident would have occurred had I not stopped, but I can definitely say that no accident occurred.

In our case, our experience and training came to our rescue. Without thinking, we knew that our first priority was to “fly the airplane,” to get the airplane back to something resembling a level flight attitude, but do it without overstressing the airplane. We didn’t have a lot of altitude to work with, as the turbulence encounter started at about 2500 feet agl and ended at 1500 feet agl.

Could This Have Been Avoided?

In a word, no! It’s really hard to decide to change course to avoid something that has absolutely no visual or other indicators. If we had happened to choose a slightly different flight path we might have missed the rotor, but that isn’t avoidance—that’s just luck.

If you fly in areas that are generally flat then you probably have little experience with the vagaries of mountain wave turbulence. However, if you fly near mountainous terrain or into the backcountry, there are many other opportunities to encounter significant turbulence. About the best you can do is to recognize conditions that are conducive to turbulence.

Understanding the wind and resulting turbulence is a topic that doesn’t seem to get a lot of press. Just because the winds are calm at the airport and the sky is clear doesn’t necessarily mean that it is a good day to go flying!

In these conditions, if the winds aloft are light, and especially in the afternoon, you are likely to have a bumpy ride from thermal turbulence. A clear path for sunlight and light winds are perfect conditions for creating thermals. A better choice might be to go fly gliders instead. Gliders thrive on thermals, and their lower speeds mean that the vertical gusts translate into much lower vertical load factors.

If the winds are calm on the ground but high at altitude, realize there is going to be a big wind shear somewhere, and with wind shear comes turbulence. Many depictions of mountain wave show a cloud in the rotor. This may be true if there is sufficient moisture in the air, but in our case there was no cloud because the humidity was too low. This is another form of clear air turbulence that airline pilots talk about—turbulence with no visual markers to identify it.

Backcountry airstrips lined with trees can have significant turbulence, especially when the wind is blowing across the runway. As the wind blows over the trees and then spills into the open area, it is going to rotate and cause turbulence that may upset an airplane close to the ground. As there will probably be no visual markers, these conditions can only be anticipated by careful awareness of the winds, topography and other conditions.

Mitigating the Effects of Turbulence

One final thing we could have done differently was simply to slow below maneuvering speed. We were at as much as 140 knots indicated, while maneuvering speed was below 96 knots. I have slowed below maneuvering speed with great effect in similar circumstances before, but in all of those cases I thought to slow down because the ride was turbulent and bumpy. In this instance, the ride was smooth, so I didn’t think it necessary to slow down. In hindsight, the clues were there (high wind speed at altitude, calm on the ground) to indicate that a large wind shear was possible, and with large wind shear comes significant turbulence.

Slowing down is important to reduce the size of the bump you feel. As you go faster, the change in angle of attack the wing sees caused by a vertical gust decreases somewhat linearly. However, the lift created by the wing still responds to that change in angle of attack by the square of the airspeed. The result is the load factor change caused by a vertical gust increases linearly with airspeed. Thus, if you slow your airspeed by one-third, the bump you feel will only be two-thirds as big.

We talk of slowing below maneuvering speed because we know that an excessive gust will cause the wing to stall before generating enough load factor to damage the structure, thus protecting the airplane. However, slowing down is also about improving aircrew comfort. If the bumps are smaller, the aircrew is less scared. However, as with most things, too much of a good thing is not good. You want to slow below maneuvering speed, but don’t slow so much that the flight controls become sluggish. That would adversely affect your ability to counter unwanted changes in aircraft attitude.

Learn From Others

It has been said before that you should learn from others’ mistakes because you won’t have time to make all of the mistakes yourself. I have been a big fan of learning from others’ experiences because there are many I don’t want to experience myself. Neither Karl nor I want to experience this one again. Learn from what we did and didn’t do because I’m pretty sure you don’t want a similar experience.

Probably fortunate you were flying experimental aircraft, I am thinking negative 3.4 G’s could get expensive in a Cessna/Piper.

I noted that you made it a point about being gentle on the stick when pulling up from a vertical attitude while staring at the ground, and another comment about the most likely immediate response from someone being what they are used to doing without thinking.

Being a flat lander from the Midwest that really got me thinking, and nervous about how I would have handled the situation. Whenever I encounter a real attitude upset condition it is ALWAYS on approach with a crosswind burbling between the hangers and over the trees. The kind of situation where you find yourself in an instant 45 degree bank at maybe 25 or 50 feet off the ground. And a quick smooth near full deflection aileron movement is the answer because of the slow speed and the need for a fast recovery.

I can’t help but think I would have quickly had the stick fully deflected in my lap, and who knows how many positive G’s I would have pulled when the upswing of the rotor combined with the dive speed.

Next time I get my “open your eyes, what a surprise” upset training, I will make it a point to internalize the instruction to recover gently to avoid overstressing the airframe.

Great analysis. You brought back many memories of MY 27 years flying in the Antelope Valley (“AV”).

I lived and worked on Edwards AFB from ’72 to ’88 (instrumentation type) and in Palmdale subsequently until ’99. I kept my airplanes at Southbase, Fox and at my private Mojave hangar variously during all of that time. I remember Rosamond before it was an airpark, too. In those days, Southbase was mostly abandoned.The Aero Club and private aircraft owners occupied T-181 and T-182. The Kern Valley airport is like few other airports around the Country, too.

People reading this article simply cannot comprehend just how bad things can get in the Mojave desert with respect to winds. Over all my years there, there were numerous crashes of light GA airplanes caused by the incessant winds, rotors and turbulence in general. Beech Bonanzas crossing the Tehachapi’s seemed especially prone to structural failures because of what you described. MY favorite breakfast locations were Woodlake (O42) and Columbia (O22). I can remember dozens of days when I’d leave Mojave in the AM in calm conditions and — on the afternoon return — hearing ferocious winds blowing and that first ‘feel’ of turbulence in the area over the Kern canyon. On one occasion, I remember seeing every windsock on Mojave blowing in a different direction AND sticking straight out. I’ve landed my 172 on one wheel more times than not because of it. I once had to get ground help to taxi between hangars there. If you can fly at Mojave, winds will never be an issue for you.

One of your sentences resonated with me … “Just because the winds are calm at the airport and the sky is clear doesn’t necessarily mean that it is a good day to go flying!” I’d say this was one of the first things I learned when I showed up on Base. There were plenty of days when you’d look out the window and see clear blue sky but develop cabin fever because you couldn’t stand up straight when outside. I once got the Aero Club T-34 in a situation where it was trying to blow over on the imaginary axis between one MLG and the NLG with a quartering tailwind while taxiing. And, I’ve seen a Cub headed for L00 climb straight up at Southbase as if it were on an elevator. I learned to hate the wind in the desert … still do.

From my perspective and experience, you guys woulda been better off flying further east and keeping it at altitude until you made your turn for the airpark. Then again, hindsight is 20/20. I’ll bet you’ll do that next time.

Two off topic comments: When I joined the Aero Club in ’72. the T-34A cost $8/hr WET !! For most my years on Base, I was on the Club BOG. I was the person who convinced them to buy a used R182 (N1668R) as opposed to a new Cutlass. I see it’s still there and I’ve heard it’s part of the TPS curriculum. Is that so? Circa 1981, I found the airplane at Santa Monica; the USAF paid $43K for it with 600 hrs TTSN !! Inflation!